3

THEORY OF OPERATION

Section Two

TRIZONE™ COOLING SYSTEM

The KitchenAid Wine Cellar features a TriZone™ Cooling System that allows storage of red wine in

the top racks at 60°F, white or blush wines in the middle racks at 50°F - 55°F, and sparkling wines in

the lower racks at 45°F in the same compartment without changing temperature settings.

Cooling is accomplished through a combination of thermostat cut-in and cut-out temperature settings,

placement of the evaporator and natural circulation of the air inside the compartment. The wine cellar

does not have an evaporator fan typically found in most refrigerator/freezers. Natural convection is

used to allow the warmer air in the compartment to "rise" while the colder air "falls". This causes a

temperature difference of approximately 15°F between the upper portion of the compartment and the

bottom. Temperatures in the middle of the compartment will be approximately 5°F to 10°F higher than

the temperature at the bottom..

The temperature control is factory preset at a mid point setting of 4½. This should allow the recom-

mended temperature range in a room with an ambient temperature of 72°F. Turning the control counter-

clockwise (a lower number) to raise the temperature inside the wine cellar. Turning the control clock-

wise (a higher number) will lower the temperature.

A number of factors will affect the internal temperatures of the cabinet:

1. Setting of the temperature control

2. Ambient room temperature

3. The number of times the door is opened and closed

4. The length of time the internal light is ON. (This affects wines primarily on the top rack.)

5. If installed in direct sun light or near a heat source

STORAGE SYSTEM

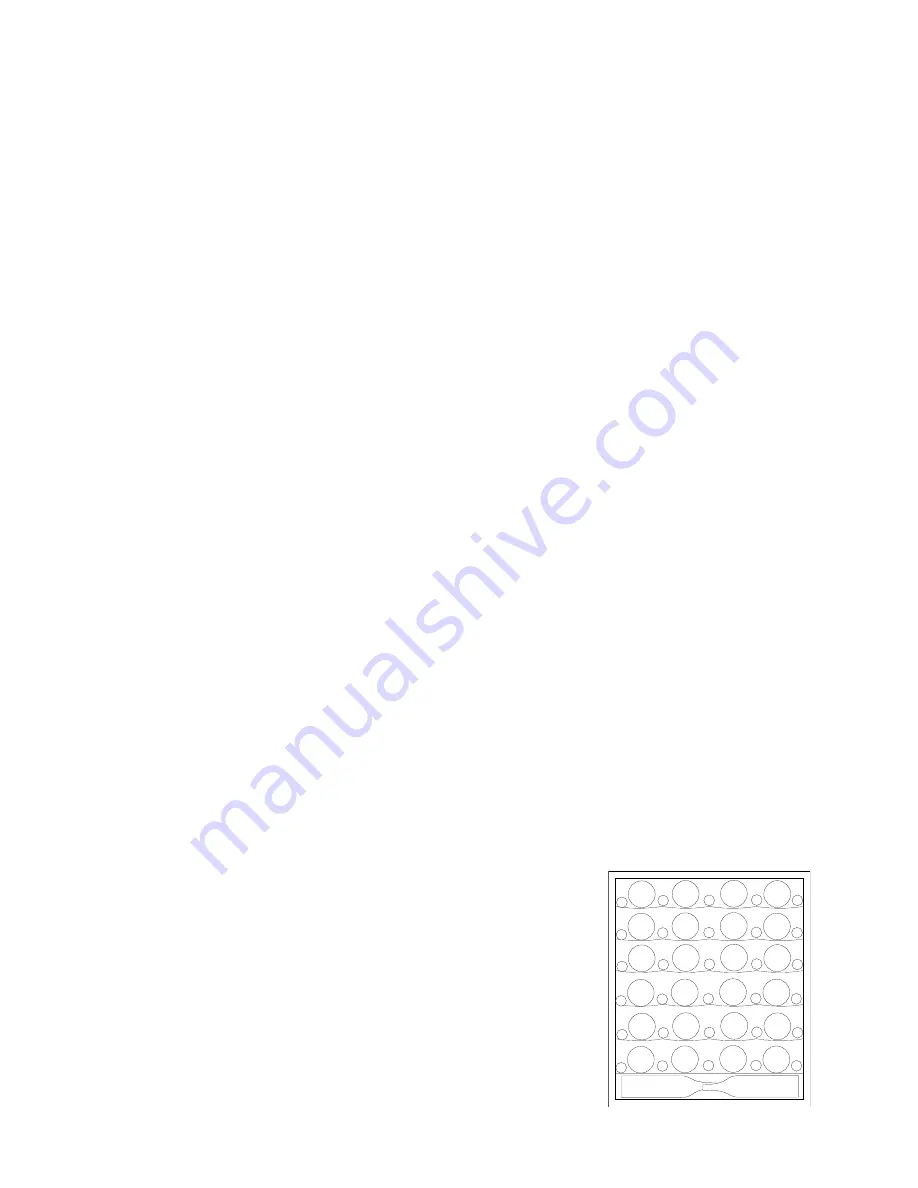

The wine racks allow for the proper horizontal storage of up to 60 bottles of wine. The bottles are

properly positioned so that the wine remains in contact with the cork to assure that the cork does not

become dry.

The racking system is designed with three parallel braces (rear, middle and front) per shelf. The

procedure for loading the rack is as follows:

1. Start at the left hand side of the rack and place the first

bottle on the rear and middle parallel braces with the

neck facing towards the front of the unit.

2. The next bottle should be placed on the front and middle

parallel braces with the neck facing towards the rear.

3. Alternate this stocking sequence moving from left to right

on each rack.

4. Flat storage is avaliable at the bottom of the

compartment.