15

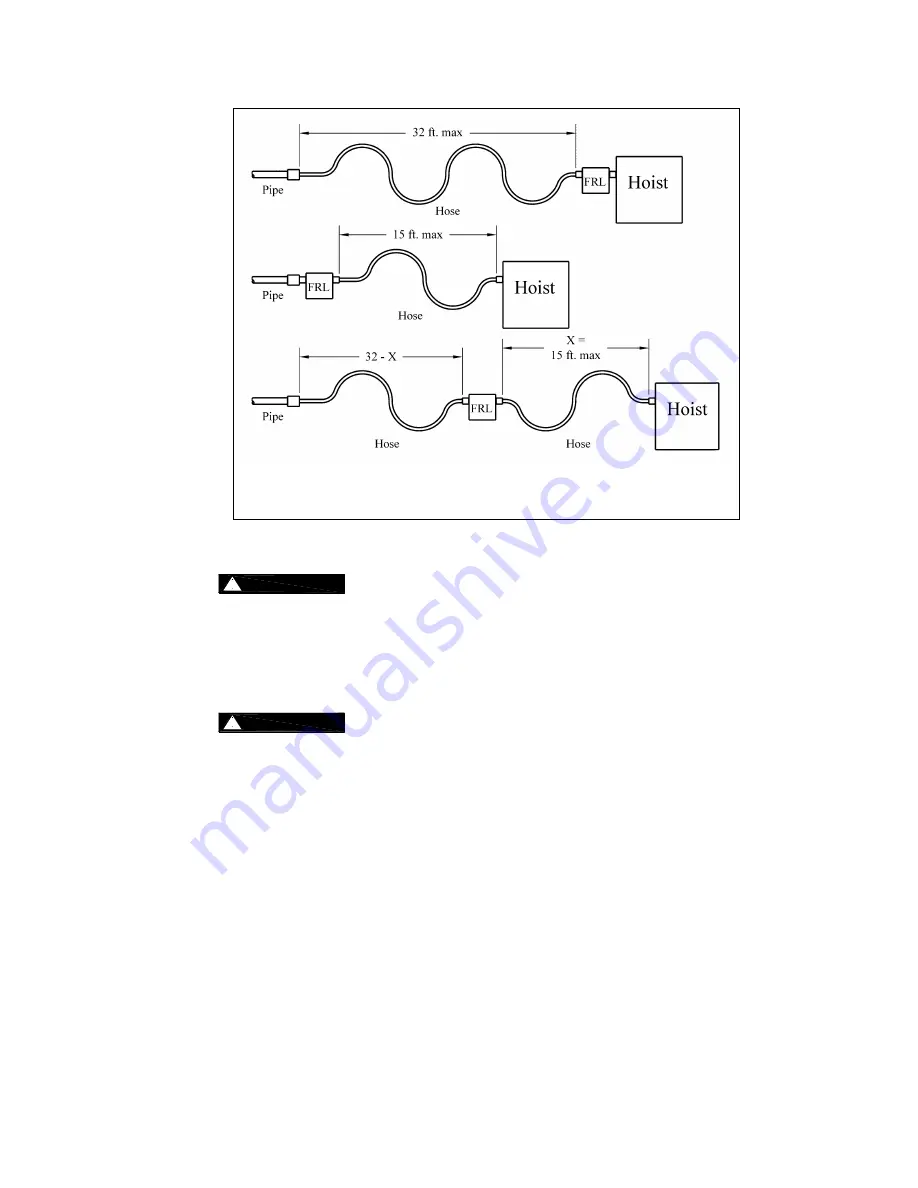

Figure 3-3

Typical Arrangements of Filter, Regulator and Lubricator and

Maximum Air Supply Hose Lengths

3.6.4

!

CAUTION

Fittings

– Important considerations regarding fittings in the hoist's air supply

include:

◼

When connecting air supply components, remove all dirt or debris from the connecting surfaces of

the hoses, pipes, fittings, or threaded fasteners to prevent contaminants from entering the hoist.

◼

Keep airflow restrictions such as quick disconnect fittings, bends, elbows, and adapters to a

minimum.

3.6.5

!

CAUTION

Before connecting the hoist to its air supply line; perform the proper draining and

purging procedures to prevent contaminants or moisture from entering the hoist.

3.7

Exhaust Control

3.7.1

Some hoist applications require the hoist exhaust to be expelled outside the immediate environment.

To accommodate this need it is possible to extend the hoist exhaust to another area. Figure 3-4

describes the method to extend the hoist exhaust.