38

6.0 Lubrication

6.1

Air Hoist Lubrication

6.1.1

This hoist is equipped with a lube-free vane motor that does not require lubrication of the supply air for

operation. However, if the hoist supply air is lubricated, there is no disadvantage. See Section 3.0 for

lubrication requirements

6.1.2

!

CAUTION

Lubrication to the motor will be provided primarily by the air supply lubricator. The

recommended amount is 10-15 drops/minute (0.2-0.3 cc/min). Refer to Table 6-1 below for the

approved lubricant for use with your air hoist.

6.1.3

Additional lubrication to the reduction gears is not necessary. When disassembling the hoist for service

or repair, apply new grease to the gears before reassembling the hoist.

6.2

Load Chain Lubrication

6.2.1

For longer life, the load chain should be lubricated.

6.2.2

The load chain lubrication should be accomplished after cleaning the load chain with an acid free

cleaning solution.

6.2.3

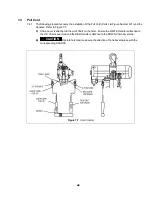

Apply KITO lubricating grease (Part No. ER1BS1951) or an equivalent to industrial general lithium

grease, NLGI No. 0, to the bearing surfaces of the load chain links as indicated by the shaded areas in

Figure 6-1. Also apply the grease to the areas of the load chain that contact the load sheave. Ensure

that the grease is applied to the contact areas in the load sheave pockets.

6.2.4

Machine or gear oil (grade ISO VG 46 or 68 oil or equivalent) may be used as an alternative lubricant

but must be applied more frequently.

Figure 6-1

Chain Grease Application

6.2.5

The chain should be lubricated every 3 months (more frequently for heavier usage or severe

conditions).

6.2.6

For dusty environments, it is acceptable to substitute a dry lubricant.

6.3

Hooks and Suspension Components

6.3.1

Hooks - Bearings should be cleaned and lubricated at least once per year for normal usage. Clean and

lubricate more frequently for heavier usage or severe conditions.

6.3.2

Suspension Pins - Lubricate at least twice per year for normal usage; more frequently for heavier usage

or severe conditions.

Summary of Contents for TCL Series

Page 43: ...43 Figure 7 4 Single Fall Chain Connections Figure 7 5 Double Fall Chain Connections ...

Page 52: ...10 1 Motor Valve Body and Controls 52 Figure 10 1 Motor Valve Body and Controls ...

Page 55: ...55 This Page Intentionally Left Blank ...

Page 61: ...61 NOTES ...

Page 62: ...62 NOTES ...

Page 63: ...63 NOTES ...