37

Table 5-3

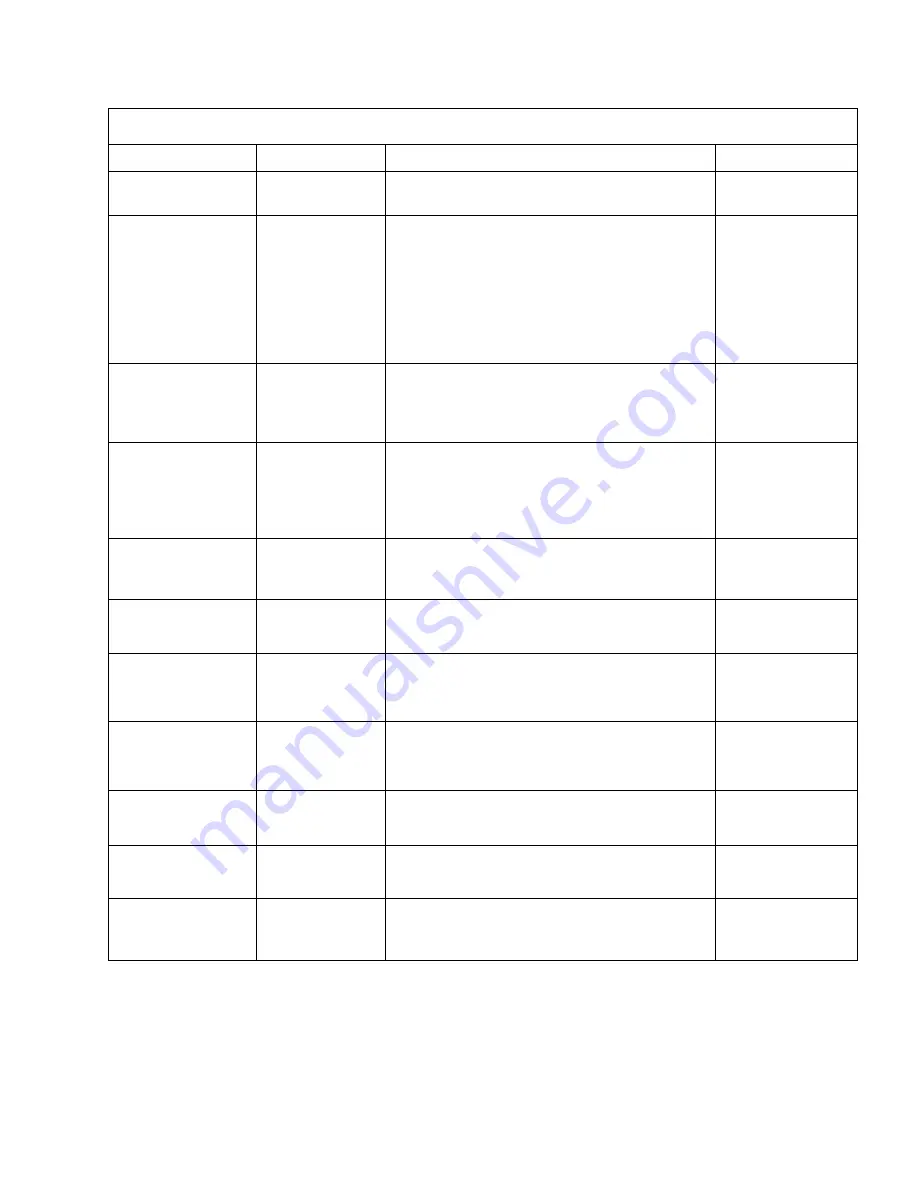

Hoist Inspection Methods and Criteria

Item

Method

Criteria

Action

Bolts, Nuts and

Rivets

Visual, Check

with Proper Tool

Bolts, nuts and rivets should not be loose.

Tighten or replace

as required.

Housing and

Mechanical

Components

Visual, Auditory,

Vibration,

Function

Hoist components including load blocks,

suspension housing, chain attachments, clevises,

yokes, suspension bolts, shafts, gears, bearings,

pins and rollers should be free of cracks,

distortion, significant wear and corrosion.

Evidence of same can be detected visually or via

detection of unusual sounds or vibration during

operation.

Replace

Chain Separator

Visual, Measure

The Chain Separator should be free of cracks,

distortion, significant wear and corrosion. The “L”

and "W" dimension should not be greater than

maximum value listed in

Table 5-5

.

Replace

Motor Brake

Measure, Visual

Motor brake dimension should be within the

allowable limits of

Table 5-4

. See

Section 7.2

for

gaining access to motor brake. Braking surfaces

should be clean, free of grease/oil and should not

be glazed.

Replace

Load Sheave

Visual

Pockets of Load Sheave should be free of

significant wear. See

Section 7.5

to gain visual

access to the load sheave.

Replace.

Pendant Control

Levers

Visual,

Function

Depressing and releasing pendant control levers

should cause hoist to operate.

Repair or replace

as necessary.

Pendant - Housing

Visual

Pendant housing should be free of cracks and

mating surfaces of parts should seal without gaps.

Replace.

Pendant - Tubing

Visual, auditory

Tubing to pendant control switches should not be

loose or be leaking air.

Repair or replace

as necessary.

Pendant - Labels

Visual

Labels denoting functions should be legible.

Replace.

Warning Labels

Visual

Warning Labels should be affixed to the hoist (see

Section 1.2

) and they should be legible.

Replace

Hoist Capacity Label Visual

The label that indicates the capacity of the hoist

should be legible and securely attached to the

hoist.

Replace.

Summary of Contents for TCR Series

Page 12: ...12 Figure 2 3 Dimensions for Manipulator TCR250 Air Hoist inches...

Page 13: ...13 2 3 Part Names Figure 2 4 Hoist Part Identification Diagrams TCR500P 500C 1000P 1000C...

Page 14: ...14 Figure 2 5 Hoist Part Identification Diagrams TCR 1000P2 1000C2 2000P2 2000C2...

Page 16: ...16 Top hook Bottom hook Figure 2 8 Hoist Part Identification Diagrams TCR250C...

Page 17: ...17 Top hook Bottom hook Figure 2 9 Hoist Part Identification Diagrams TCR250P...

Page 18: ...18 Top hook Bottom hook Figure 2 10 Hoist Part Identification Diagrams TCR250M...

Page 51: ...Kito Air Hoists Parts List...

Page 52: ...TCR250 MAIN BODY 52 9 0 Parts List TCR250 Main Body...

Page 54: ...TCR250 VALVE BODY 54 TCR250 Valve Body...

Page 56: ...TCR250 MANIPULATOR CONTROL 56 TCR250M Manipulator Control...

Page 58: ...TCR500 MAIN BODY TCR500 Main Body TCR500 Main Body 58...

Page 60: ...TCR1000 2 Main Body TCR1000 2 Main Body 60...

Page 62: ...TCR1000 Main Body TCR1000 Main Body 62...

Page 64: ...TCR2000 2 Main Body TCR2000 2 Main Body 64...

Page 66: ...TCR3000 Main Body TCR3000 Main Body 66...

Page 68: ...TCR6000 2 Main Body TCR6000 2 Main Body 68...

Page 70: ...Cord Control Valve Body Cord Control Valve Body 70...

Page 72: ...Pendant Control Valve Body 72 Pendant Control Valve Body...