english 11

21

ATTENTION!

–

The use of other insertion tools and other acces-

sories can entail a risk of injury.

22

Have your electric tool repaired by a qualified

electrician

–

This electric tool conforms to the applicable safe-

ty regulations. Repairs may only be performed by

an electrician using original spare parts. Other-

wise accidents can occur.

Additional safety rules for the belt and disc sanding machine

•

WARNING:

Do not use your machine until it is completely

assembled and installed according to the instructions.

• If you are not familiar with the operation of the sanding

machine, ask the head of the department, your teacher,

or any other qualified person.

•

ATTENTION:

This machine has only been designed for

sanding wood or similar materials. The sanding of other

materials can cause fire, injuries, or damage the prod-

uct.

• Always wear safety goggles.

• This machine may only be operated indoors.

•

IMPORTANT:

Mount and use the machine on a horizontal

surface. A non-horizontal surface can damage the motor.

• If the machine tends to tilt or walk (especially when

sanding long and heavy panels), it must be fastened to a

solid surface of sufficient carrying force.

• Make sure the sanding belt runs in the correct direction

– see arrows at the back of the belt.

• Make sure the sanding belt is running correctly so that it

cannot come off the drive pulleys.

• Make sure the sanding belt is not twisted or loose.

• Firmly hold the workpiece when sanding.

• Always use the fence when using the sanding machine

in horizontal position.

• Always hold the workpiece firmly to the table when using

the sanding disc.

• Always hold the workpiece to the side of the sanding

disc running downwards, in order to maintain the work-

piece pressed to the table. By using the upward-running

side of the sanding disc, the workpiece could be ejected

and cause injury to persons.

• Always keep a minimum distance of about 1.5 mm or

less between the table or fence and the sanding belt or

disc.

• Do not wear gloves. Do not hold the workpiece with a

cloth during sanding.

• Use sanding belt or disc of the correct grit corresponding

with the wood.

• Never sand workpieces too small to be held safely.

• Avoid awkward hand positions where a sudden slip could

cause your hand to touch the sanding belt or disc.

• When sanding a large piece of material, provide an ad-

ditional support at table height.

• Never sand an unsupported workpiece. Secure the work-

piece with the table or the fence. Exceptions are the

sanding of curved workpieces on the outside of the sand-

ing disc.

• Always clear the table, fence or sanding belt of scraps or

other objects, before turning the machine on.

• Do not perform any layout assembly or set-up work on

the table while the sanding machine is in operation.

• Switch the machine off and pull the power plug from the

socket when fitting or removing accessories.

• Never leave the working area of the sanding machine

while the tool is running, or as long as it has not come to

an absolute standstill.

m

Proper Use

The machine meets the currently valid EU machine directive.

• The manufacturer’s safety, operation and maintenance

instructions as well as the technical data given in the

calibrations and dimensions must be adhered to.

• Relevant accident prevention regulations and other gen-

erally recognized safety and technical rules must also be

adhered to.

• The machine may only be used, maintained or repaired

by trained persons who are familiar with the machine

and have been informed about the dangers. Unauthor-

ized modifications of the machine exclude a liability of

the manufacturer for damages resulting from the modifi-

cations.

• The machine is intended for use only with original spare

parts and original tools from the producer.

• Any other use is considered to be not intended. The

manufacturer excludes any liability for resulting dam-

ages, the risk is exclusively borne by the user.

Please note that our equipment has not been designed

for use in commercial, trade or industrial applications.

Our warranty will be voided if the equipment is used

in commercial, trade or industrial businesses or for

equivalent purposes.

m

Remaining hazards

The machine has been built using modern technology and

in accordance with recognized safety rules.

Some hazards, however, may still remain.

• The grinding wheel poses a danger of injury to fingers

and hands by improper feeding or placement of tools.

• Danger of injury from thrown tools due to improper hold-

ing or feeding.

• The use of incorrect or damaged mains cables can lead

to electrical injuries.

• Although having regarded all considerable rules there

may still remain not obvious remaining hazrds.

• Minimize remaining hazards by following the instruc-

tions in ”Safety Rules”, ”Use only as authorized” and in

the entire operating manual.

Commissioning

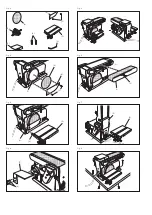

Installing sanding disc and disc guard, Fig. 4

WARNING:

Do not connect to power supply until assembly

is complete. Failure to comply could result in accidental

starting and possible serious injury.

• Align perimeter of sanding disc with plate and press

firmly into position.

• Position disc guard against the lower one-third of the

disc, aligning holes as shown in figure 4.

• Using the two phillips head screws, securely tighten the

disc guard into place.

Installing/Replacing sanding belt, Fig. 5.

On the smooth side of the sanding belt, there is a direc-

tional arrow. The sanding belt must run in the direction of

the arrow.

• Pull the tension lever toward you to release belt tension.

• Place the sanding belt over the drive drum and idler drum

with the directional arrows running counterclockwise. Be

sure the sanding belt is centered on both drums.

• Push the tension lever back into place to apply the belt

Summary of Contents for 3403301901

Page 26: ......