73 / 77

83000102.Kf

II.

II.

II.

II.

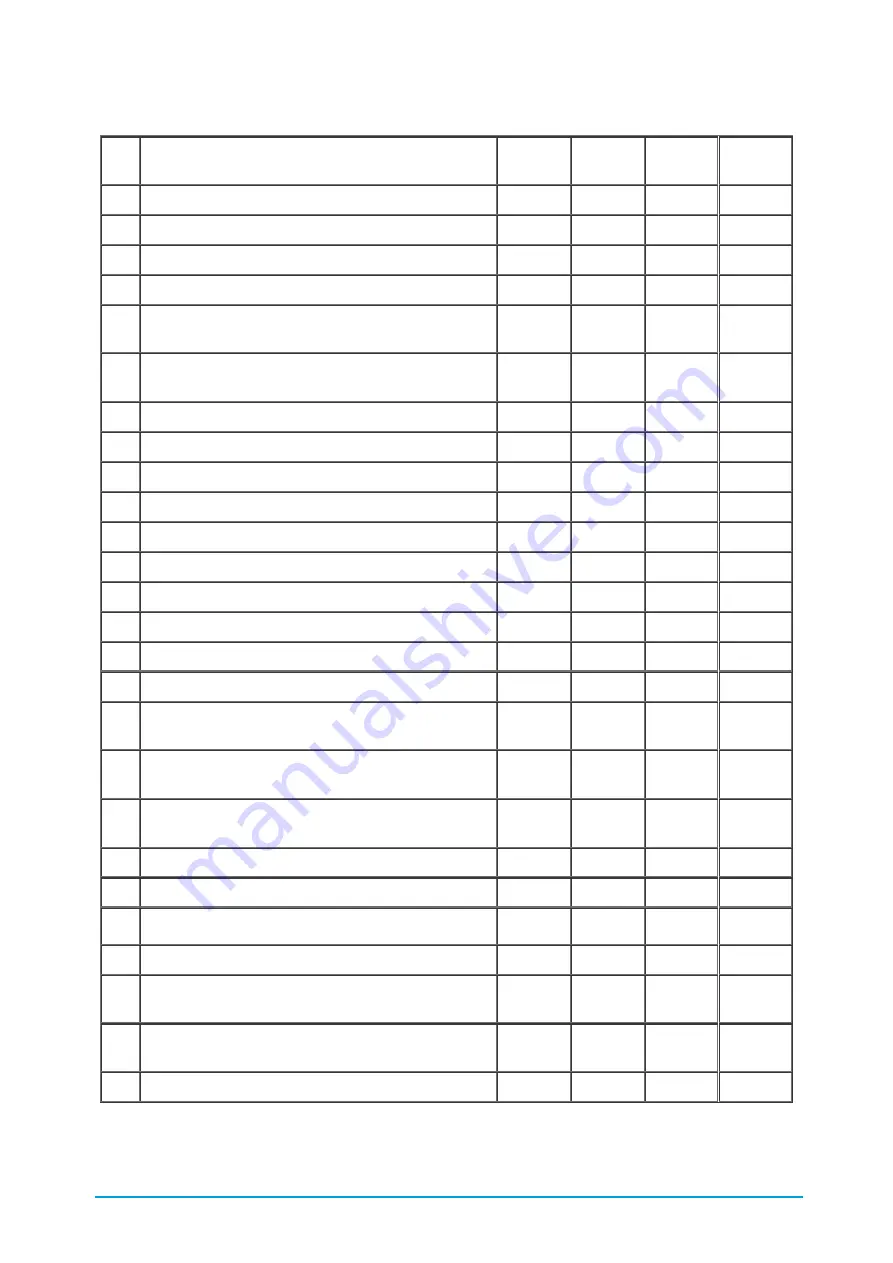

Maintenance intervals in accordance with the VDMA

Maintenance intervals in accordance with the VDMA

Maintenance intervals in accordance with the VDMA

Maintenance intervals in accordance with the VDMA

Explanation

Explanation

Explanation

Explanation

Annual

Annual

Annual

Annual

Six

Six

Six

Six----

monthly

monthly

monthly

monthly

as

as

as

as

required

required

required

required

Remark

Remark

Remark

Remark

Compressor

Compressor

Compressor

Compressor

1

Optical check for dirt, damage and corrosion

x

x

2

Check fixing, check running noises

x

3

Measure the intake pressure

x

4

Measure the suction gas temperature upstream

of the compressor

x

5

Measure the compression end temperature at

the discharge port

x

6

Check the oil level

x

7

Check the acid content of the oil (acid test)

x

8

Oil change

x

9

Check that the crankcase heater is working

x

10

Check that the output control is working

x

11

Check the refrigerant side for leaks

x

12

Check high/low pressure switching equipment

x

Air

Air

Air

Air----cooled condenser

cooled condenser

cooled condenser

cooled condenser

20

Optical check for dirt, damage and corrosion

x

x

21

Measure the condensing temperature

x

22

Measure the refrigerant side supercooling

temperature at the condenser outlet

x

23

Measure the medium temperature at condenser

inlet and outlet

x

24

Check that the condensation pressure control is

functioning properly

x

25

Check the refrigerant side for leaks

x

Evaporator

Evaporator

Evaporator

Evaporator

30

Optical check for dirt, damage and corrosion

x

31

Measure refrigerant overheating temperature

x

32

Measure the medium temperature at the

evaporator inlet and outlet

x

33

Measure the anti-freeze temperature (freezing

point) of the heat transfer media

x

34

Check the water and refrigerant side for leaks

x