KLARO GmbH

10

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

2.4. Exclusion for Use

The controller has been specially developed for use in SBR small wastewater treatment plants. The

controller must not be used in areas that pose a threat to life and limb:

•

Control of machines, vehicles, and safety processes,

•

Research technology in handling of hazardous substances,

•

Medical technology,

•

Nuclear power engineering,

•

etc.

3.

Warranty

The plant/conversion kit has been dimensioned and manufactured according to the state of the art. The

product has left the factory in a faultless condition. As part of the warranty, defects due to manufacturing

or the material will be repaired free of charge. These defects must have demonstrably occurred in spite

of correct installation and compliance with the conditions of use in accordance with these installation

instructions. After delivery, please inspect the controller for any damage. In the event of defects, please

contact your contractors/dealer immediately with a description of the defect and the plant identification.

Our terms and conditions are binding.

We expressly state that the warranty is void in the event of:

•

Improper installation,

•

Unconventional use,

•

Deluge,

•

Lightning and other overvoltages.

4.

Function of the SBR Plant

KLARO and KLARO Easy are fully biological small wastewater treatment plants, operating on the

principle of the SBR process (activated sludge plant with sequencing batch reactor) . The SBR plant is

designed for the treatment of the entire household wastewater. The introduction of other wastewater, for

example, the wastewater from restaurants and/or business entities, etc., is permissible if this use was

already known and taken into account during the design of the plant.

Biocides, toxic, or biologically incompatible substances must not enter into the system as they interfere

with bacteria, important for wastewater treatment, and cause biological process problems (detailed

information found on the following pages).

Operation in accordance with our operating and maintenance instructions is essential for compliance with

regulatory treatment requirements. You can find these instructions on the following pages.

The system essentially consists of 2 stages: A sludge storage with integrated pre-buffer and an activated

sludge stage in a closed sequencing batch reactor (SBR).

The upstream sludge storage with integrated buffer has the following functions:

- Storage of primary and secondary sludge,

- Retention of settling solids and floating substances,

- Storage of feed water,

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

11

- Balance of volume and concentration-related fluctuations in the wastewater inflow.

The wastewater treatment plant operation takes place via a microprocessor controller, which controls the

air compressor and the air distributor for the various lifters via solenoid valves.

Your responsible Commissioner for Water Authority has established limit values for the water quality of

the treated wastewater. Accordingly, you have purchased a system with the process class that safely

complies with those limits.

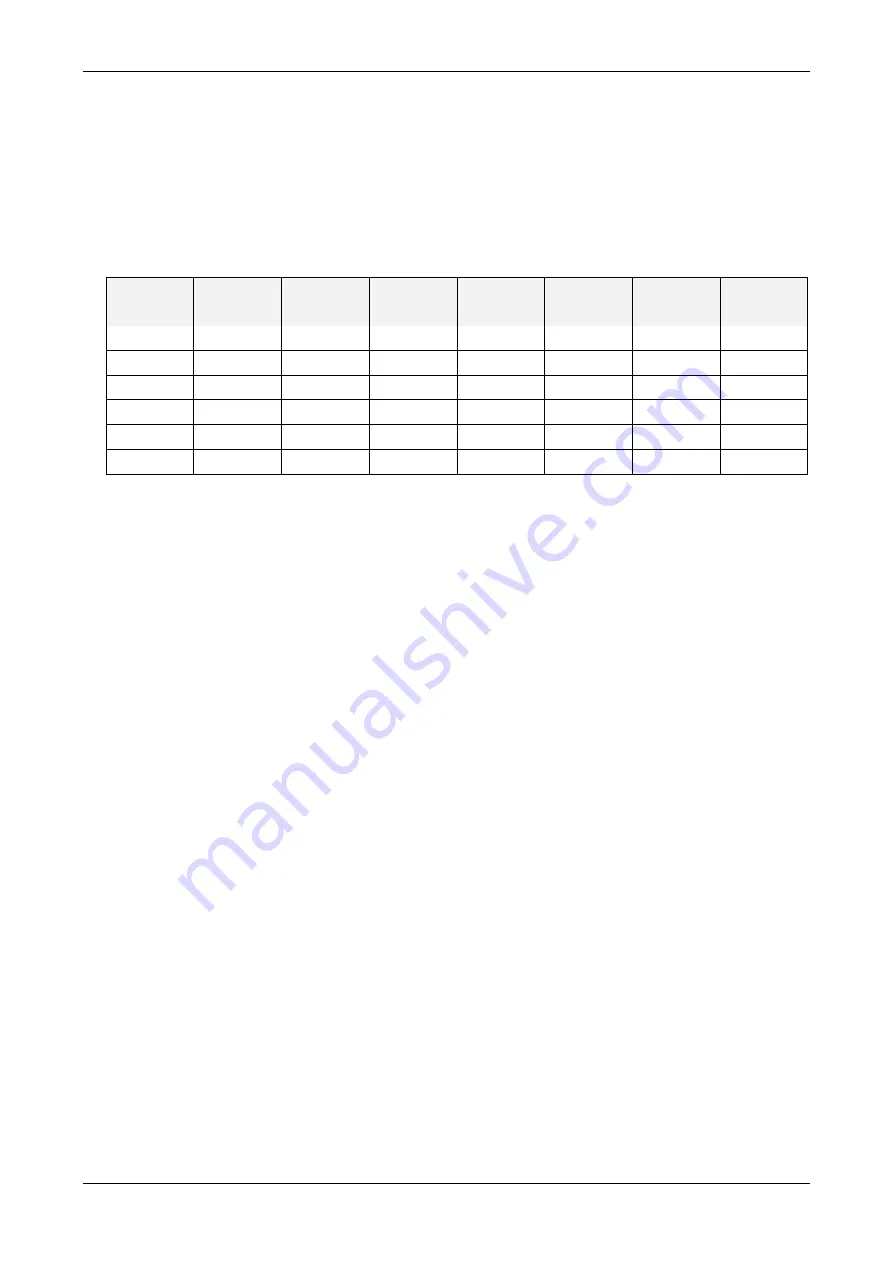

Process

Class

CSB

BOD

5

NH

4

-N

N

anorg

AFS

FC germs

P

tot

[mg/l]

[mg/l]

[mg/l]

[mg/l]

[mg/l]

[ml]

[mg/l]

C

≤ 150

≤ 40

-

-

≤ 75

-

-

N

≤ 90

≤ 20

≤ 10

-

≤ 50

-

-

D

≤ 90

≤ 20

≤ 10

≤ 25

≤ 50

-

-

+S

-

-

-

-

-

≤ 100/100

-

+P

-

-

-

-

-

-

≤ 2

•

Process class C: Carbon reduction

•

Process class N: Carbon reduction and additional nitrification

•

Process class D: Carbon reduction, nitrification, and denitrification

•

Process class P: with additional means for phosphorus elimination

•

Process class H: with additional means for sanitation of effluent water

4.1. Plants for carbon elimination (process classes C)

The process is a sequence of 5 steps, which take place successively in time and are repeated several

times a day (usually 4 times).

-

Step 1 (valve 1): Charging

-

The raw wastewater temporarily stored in the sludge storage is fed to the SBR via an airlift. The

airlift is positioned so that only solid-free water is pumped. Through the special design of the

lifter, a minimum water level is guaranteed in the sludge storage. Limiting the water level through

other components (e.g., a float switch) is therefore not required.

KLARO GmbH

2

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

IMPORTANT:

•

This Operating Manual contains information about the plant, from installation

to maintenance, and must therefore be read before commissioning of the

plant!

•

All safety instructions must be observed!

•

The Operating Manual must be kept readily available during the operation of

the plant!

Plant Specifications

For any questions in the course of the operation of the plant, the specifications of your plant should

be noted as follows. With the help of this information, our staff will be able to help you more quickly

in the event of a malfunction. The specifications can be found on the nameplate, which is located

on the outside of the cabinet door for indoor cabinets, and inside the cabinet for outdoor cabinets.

Small Wastewater Treatment

Plant

PT

Sludge storage

Buffer

SB-Reactor

Approval No.:

Process class:

Certified:

Cabinet:

Controller:

Compressor:

Denomination:

Serial No.:

Article No.:

Additional module:

Article No.:

El. Connected load:

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

3

CONTENTS

Page

1.

About this Operating Manual

6

1.1.

Original Language of Documentation

6

1.2.

Completeness

6

1.3.

Liability

7

2.

Safety

7

2.1.

Explanation of Warnings and Prohibitions

7

2.2.

Hazard statements

8

2.3.

Warnings

9

2.4.

Exclusion for Use

10

3.

Warranty

10

4.

Function of the SBR Plant

10

4.1.

Plants for carbon elimination (process classes C)

11

4.2.

Systems with Additional Nitrogen Removal (Process Classes N and D)

13

4.3.

Systems with Additional Phosphate Elimination (Process Class +P)

13

4.4.

Systems with Additional Sanitation (Process Class +S)

13

5.

Control of the Small Wastewater Treatment Plant

13

5.1.

Connections to the KL-controls (230V option for solenoid valves)

16

5.2.

Connections to the KL24 controller(24V option for stepper motor valves)

16

5.3.

Operating the Controller

18

5.3.1.

Querying Operating Hours

18

5.3.2.

Manual Control of the Valves and the Cabinet Fan in "Manual Mode"

19

5.3.3.

Setting Date/Time

20

5.3.4.

Set Holiday Mode

20

5.3.5.

Query Malfunctions - Query Old Malfunctions

21

5.3.6.

Display Settings

21

5.3.7.

Service Menu and Action Code

21

5.4.

Changing the Fuses

22

5.5.

Operation of Power Failure Detector

22

6.

Additional functions of the Controllers KLplus/ KL24plus and KLbasic/KL24base

23

6.1.

Underload detection (KLplus/KL24plus)

23

6.1.1.

Mode of Operation

24

6.1.2.

Commissioning

24

6.1.3.

Switching Off the Level Measurement

25

6.1.4.

Safety and Fault Messages

25

6.2.

Optional Functions

26

6.2.1.

Connection of an external alarm device

26

6.2.2.

Connection of a contactor for switching the compressor

26

6.2.3.

Connection of a UV reactor

26

6.2.4.

Phosphate precipitation with metering pump

26

7.

Maintenance, Repair and Operation

28

7.1.

Sludge Evacuation

28

7.2.

Operating Instructions

29

8.

Fault Messages and Troubleshooting

31

8.1.

Fault Message on the Display

32

8.2.

Unusual Water Levels - Troubleshooting

33

KLARO GmbH

2

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

IMPORTANT:

•

This Operating Manual contains information about the plant, from installation

to maintenance, and must therefore be read before commissioning of the

plant!

•

All safety instructions must be observed!

•

The Operating Manual must be kept readily available during the operation of

the plant!

Plant Specifications

For any questions in the course of the operation of the plant, the specifications of your plant should

be noted as follows. With the help of this information, our staff will be able to help you more quickly

in the event of a malfunction. The specifications can be found on the nameplate, which is located

on the outside of the cabinet door for indoor cabinets, and inside the cabinet for outdoor cabinets.

Small Wastewater Treatment

Plant

PT

Sludge storage

Buffer

SB-Reactor

Approval No.:

Process class:

Certified:

Cabinet:

Controller:

Compressor:

Denomination:

Serial No.:

Article No.:

Additional module:

Article No.:

El. Connected load:

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

3

CONTENTS

Page

1.

About this Operating Manual

6

1.1.

Original Language of Documentation

6

1.2.

Completeness

6

1.3.

Liability

7

2.

Safety

7

2.1.

Explanation of Warnings and Prohibitions

7

2.2.

Hazard statements

8

2.3.

Warnings

9

2.4.

Exclusion for Use

10

3.

Warranty

10

4.

Function of the SBR Plant

10

4.1.

Plants for carbon elimination (process classes C)

11

4.2.

Systems with Additional Nitrogen Removal (Process Classes N and D)

13

4.3.

Systems with Additional Phosphate Elimination (Process Class +P)

13

4.4.

Systems with Additional Sanitation (Process Class +S)

13

5.

Control of the Small Wastewater Treatment Plant

13

5.1.

Connections to the KL-controls (230V option for solenoid valves)

16

5.2.

Connections to the KL24 controller(24V option for stepper motor valves)

16

5.3.

Operating the Controller

18

5.3.1.

Querying Operating Hours

18

5.3.2.

Manual Control of the Valves and the Cabinet Fan in "Manual Mode"

19

5.3.3.

Setting Date/Time

20

5.3.4.

Set Holiday Mode

20

5.3.5.

Query Malfunctions - Query Old Malfunctions

21

5.3.6.

Display Settings

21

5.3.7.

Service Menu and Action Code

21

5.4.

Changing the Fuses

22

5.5.

Operation of Power Failure Detector

22

6.

Additional functions of the Controllers KLplus/ KL24plus and KLbasic/KL24base

23

6.1.

Underload detection (KLplus/KL24plus)

23

6.1.1.

Mode of Operation

24

6.1.2.

Commissioning

24

6.1.3.

Switching Off the Level Measurement

25

6.1.4.

Safety and Fault Messages

25

6.2.

Optional Functions

26

6.2.1.

Connection of an external alarm device

26

6.2.2.

Connection of a contactor for switching the compressor

26

6.2.3.

Connection of a UV reactor

26

6.2.4.

Phosphate precipitation with metering pump

26

7.

Maintenance, Repair and Operation

28

7.1.

Sludge Evacuation

28

7.2.

Operating Instructions

29

8.

Fault Messages and Troubleshooting

31

8.1.

Fault Message on the Display

32

8.2.

Unusual Water Levels - Troubleshooting

33

11