KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

57

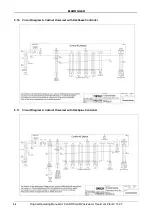

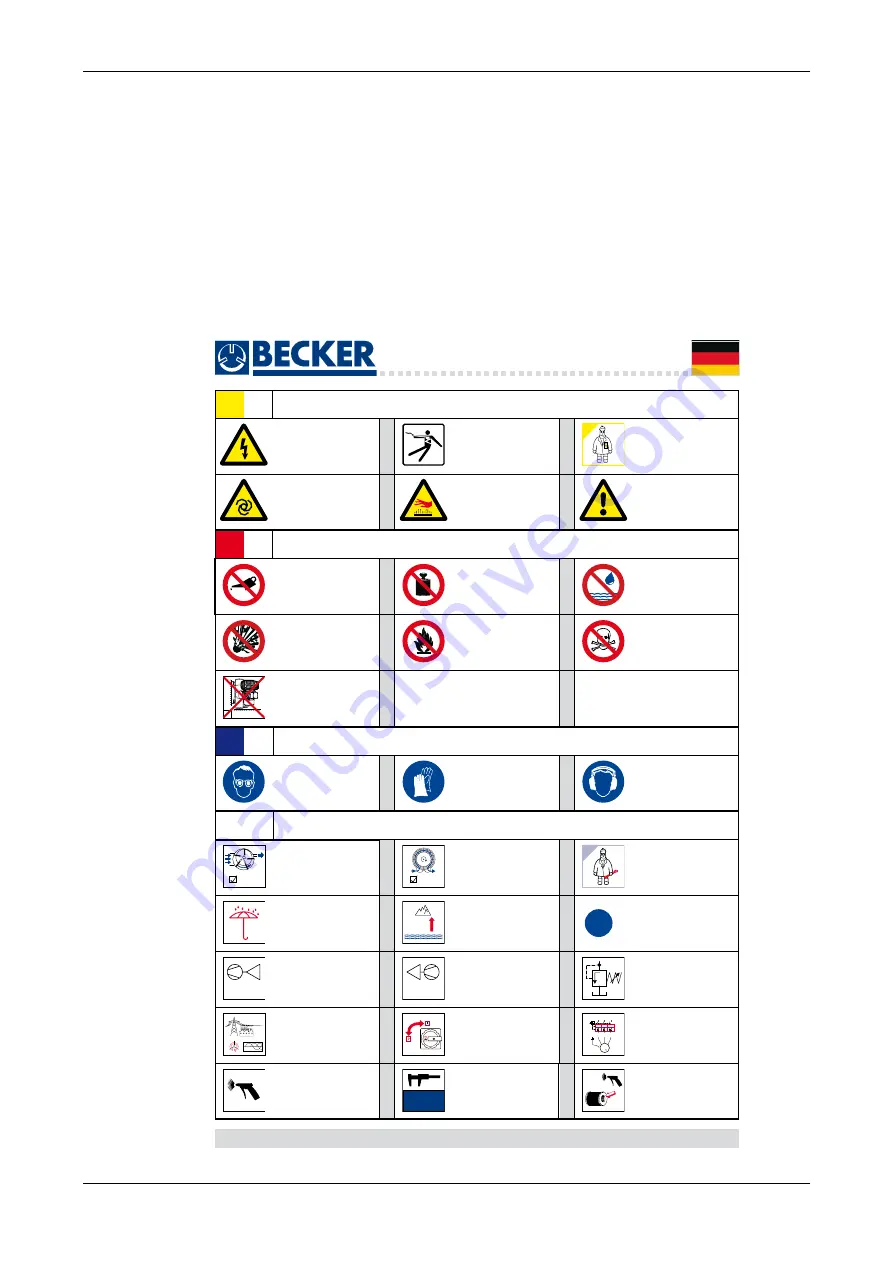

13.2. Rotary Vane Compressor Becker and Rietschle

Note:

The Becker rotary vane compressor we use are equipped with a pressure relief valve, which is factory set to

a maximum pressure of 0.5 bar.

With our plants, an operating pressure of <0.3 bar is common. If a pressure > 0.5 bar occurs in the plant

(e.g., in case of a kinked air hose), a portion of the air is released through the relief valve. The compressor is

thus protected from damage or excessive wear.

www.becker-international.com

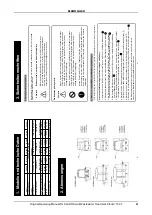

Warnhinweise

1.

Verbote

2.

Oil

Gebote

3.

Hinweise

4.

Schutzhandschuhe

tragen

Gehörschutz aufsetzen

Info über Schallpegel

z.B. 85 dB(A)

Schutzbrille aufsetzen

AIR

$,5

max.

800m

-

p

VACUUM

+

p

PRESSURE

L1

L2

L3

L1

L3

L2

50/60 Hz

=OFF

=ON

3000 h

i

+

L2 L1 L3

I

>

I

>

I

>

M

3

U1 V1 W1

Gefährliche Spannung

nach

ANSI

Z535

(

A

merican

N

ational

S

tandards

I

nstitute)

Elektrofachkraft

gekennzeichnete Arbeits-

schritte dürfen nur durch

ausgebildete Elektrofach-

kraft erfolgen

Elektrische Spannung

kann tödlich sein.

Arbeiten an der Elektrik

nur durch ausgebildete

Elektrofachkraft

Automatischer Anlauf

möglich. Bei Service-

arbeiten das Gerät stets

stromlos schalten.

Heiße Oberflächen

führen zu Verbrennungen.

Vor Wartungarbeiten

Gerät abkühlen lassen.

Achtung

Bei Nichtbeachtung kann

die Pumpe erheblich

beschädigt werden

Pumpe arbeitet ölfrei

Ansaugung von Ölnebel

vermeiden

Gekennzeichnete Stellen

nicht belasten

Explosive Stoffe

dürfen nicht gefördert

werden

Giftstoffe

dürfen nicht gefördert

werden

Brennstoffe

dürfen nicht gefördert

werden

Flüssigkeiten

dürfen nicht gefördert

werden

Aufstellung

unzulässige Einbaulage

Wirkprinzip

Drehschieberpumpe

Nur Luft ist als Förder-

medium zulässig

Wirkprinzip

Seitenkanalgebläse

Nur Luft ist als Förder-

medium zulässig

Wartungsarbeiten

gekennzeichnete Arbeits-

schritte regelmäßig

ausführen.

Sicherheitsventil

Ausführung

Vakuumpumpe

Ausführung

Verdichter

werksseitiges

Drehfeld

rechtsdrehend

als Voraussetzung für

Pumpenanschluß

Schaltintervall

nicht mehr als

10x

pro Stunde

Wartung (Filter)

je nach Staubanfall reinigen

verstopfte Patronen erneuern

alte Patrone entsorgen

gekennzeichnete

Bereiche mit Druckluft

ausblasen

Wartungsintervall

hier für Schiebermessung

nach 3.000 Betriebstunden.

(Mindestmaß beachten)

Motorschutzschalter

vorsehen

Lagerung / Aufstellung

Pumpe

vor Nässe

schützen

Aufstellung

Kenndaten

gelten bis zu

einer Höhe von 800m

weitere Informationen

(optionale Daten)

- Typenschilder

- Internet

KLARO GmbH

2

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

IMPORTANT:

•

This Operating Manual contains information about the plant, from installation

to maintenance, and must therefore be read before commissioning of the

plant!

•

All safety instructions must be observed!

•

The Operating Manual must be kept readily available during the operation of

the plant!

Plant Specifications

For any questions in the course of the operation of the plant, the specifications of your plant should

be noted as follows. With the help of this information, our staff will be able to help you more quickly

in the event of a malfunction. The specifications can be found on the nameplate, which is located

on the outside of the cabinet door for indoor cabinets, and inside the cabinet for outdoor cabinets.

Small Wastewater Treatment

Plant

PT

Sludge storage

Buffer

SB-Reactor

Approval No.:

Process class:

Certified:

Cabinet:

Controller:

Compressor:

Denomination:

Serial No.:

Article No.:

Additional module:

Article No.:

El. Connected load:

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

3

CONTENTS

Page

1.

About this Operating Manual

6

1.1.

Original Language of Documentation

6

1.2.

Completeness

6

1.3.

Liability

7

2.

Safety

7

2.1.

Explanation of Warnings and Prohibitions

7

2.2.

Hazard statements

8

2.3.

Warnings

9

2.4.

Exclusion for Use

10

3.

Warranty

10

4.

Function of the SBR Plant

10

4.1.

Plants for carbon elimination (process classes C)

11

4.2.

Systems with Additional Nitrogen Removal (Process Classes N and D)

13

4.3.

Systems with Additional Phosphate Elimination (Process Class +P)

13

4.4.

Systems with Additional Sanitation (Process Class +S)

13

5.

Control of the Small Wastewater Treatment Plant

13

5.1.

Connections to the KL-controls (230V option for solenoid valves)

16

5.2.

Connections to the KL24 controller(24V option for stepper motor valves)

16

5.3.

Operating the Controller

18

5.3.1.

Querying Operating Hours

18

5.3.2.

Manual Control of the Valves and the Cabinet Fan in "Manual Mode"

19

5.3.3.

Setting Date/Time

20

5.3.4.

Set Holiday Mode

20

5.3.5.

Query Malfunctions - Query Old Malfunctions

21

5.3.6.

Display Settings

21

5.3.7.

Service Menu and Action Code

21

5.4.

Changing the Fuses

22

5.5.

Operation of Power Failure Detector

22

6.

Additional functions of the Controllers KLplus/ KL24plus and KLbasic/KL24base

23

6.1.

Underload detection (KLplus/KL24plus)

23

6.1.1.

Mode of Operation

24

6.1.2.

Commissioning

24

6.1.3.

Switching Off the Level Measurement

25

6.1.4.

Safety and Fault Messages

25

6.2.

Optional Functions

26

6.2.1.

Connection of an external alarm device

26

6.2.2.

Connection of a contactor for switching the compressor

26

6.2.3.

Connection of a UV reactor

26

6.2.4.

Phosphate precipitation with metering pump

26

7.

Maintenance, Repair and Operation

28

7.1.

Sludge Evacuation

28

7.2.

Operating Instructions

29

8.

Fault Messages and Troubleshooting

31

8.1.

Fault Message on the Display

32

8.2.

Unusual Water Levels - Troubleshooting

33

KLARO GmbH

2

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

IMPORTANT:

•

This Operating Manual contains information about the plant, from installation

to maintenance, and must therefore be read before commissioning of the

plant!

•

All safety instructions must be observed!

•

The Operating Manual must be kept readily available during the operation of

the plant!

Plant Specifications

For any questions in the course of the operation of the plant, the specifications of your plant should

be noted as follows. With the help of this information, our staff will be able to help you more quickly

in the event of a malfunction. The specifications can be found on the nameplate, which is located

on the outside of the cabinet door for indoor cabinets, and inside the cabinet for outdoor cabinets.

Small Wastewater Treatment

Plant

PT

Sludge storage

Buffer

SB-Reactor

Approval No.:

Process class:

Certified:

Cabinet:

Controller:

Compressor:

Denomination:

Serial No.:

Article No.:

Additional module:

Article No.:

El. Connected load:

KLARO GmbH

Original Operating Manual for KLARO Small Wastewater Treatment Plant V.15.07

3

CONTENTS

Page

1.

About this Operating Manual

6

1.1.

Original Language of Documentation

6

1.2.

Completeness

6

1.3.

Liability

7

2.

Safety

7

2.1.

Explanation of Warnings and Prohibitions

7

2.2.

Hazard statements

8

2.3.

Warnings

9

2.4.

Exclusion for Use

10

3.

Warranty

10

4.

Function of the SBR Plant

10

4.1.

Plants for carbon elimination (process classes C)

11

4.2.

Systems with Additional Nitrogen Removal (Process Classes N and D)

13

4.3.

Systems with Additional Phosphate Elimination (Process Class +P)

13

4.4.

Systems with Additional Sanitation (Process Class +S)

13

5.

Control of the Small Wastewater Treatment Plant

13

5.1.

Connections to the KL-controls (230V option for solenoid valves)

16

5.2.

Connections to the KL24 controller(24V option for stepper motor valves)

16

5.3.

Operating the Controller

18

5.3.1.

Querying Operating Hours

18

5.3.2.

Manual Control of the Valves and the Cabinet Fan in "Manual Mode"

19

5.3.3.

Setting Date/Time

20

5.3.4.

Set Holiday Mode

20

5.3.5.

Query Malfunctions - Query Old Malfunctions

21

5.3.6.

Display Settings

21

5.3.7.

Service Menu and Action Code

21

5.4.

Changing the Fuses

22

5.5.

Operation of Power Failure Detector

22

6.

Additional functions of the Controllers KLplus/ KL24plus and KLbasic/KL24base

23

6.1.

Underload detection (KLplus/KL24plus)

23

6.1.1.

Mode of Operation

24

6.1.2.

Commissioning

24

6.1.3.

Switching Off the Level Measurement

25

6.1.4.

Safety and Fault Messages

25

6.2.

Optional Functions

26

6.2.1.

Connection of an external alarm device

26

6.2.2.

Connection of a contactor for switching the compressor

26

6.2.3.

Connection of a UV reactor

26

6.2.4.

Phosphate precipitation with metering pump

26

7.

Maintenance, Repair and Operation

28

7.1.

Sludge Evacuation

28

7.2.

Operating Instructions

29

8.

Fault Messages and Troubleshooting

31

8.1.

Fault Message on the Display

32

8.2.

Unusual Water Levels - Troubleshooting

33

57