Instruction

Manual

page

8

______________________________________________________________________________________________________________________

Instruction Manual

for the mains driven electric-hydraulic universal unit,

Serial-No. ..........................

Index

1

Introduction

2

Labels

3

Warranty

4

Description of the electric-hydraulic universal unit

4.1

Description of the components

4.2

Brief description of the important features of the unit

5

Remarks in respect of the determined use

5.1

Operation of the unit

5.1.1

Use of the crimping dies

5.1.2

Use of the cutting dies

5.1.3

Use of the punch adapter

5.2

Explanation of the application range

5.3

Mounting instructions

5.4

Service and Maintenance instructions

5.5

Storage and transport of the crimping unit.

6 Troubleshooting

7

Putting out of operation/waste disposal

8 Technical

data

Symbols

Safety warnings

Please do not disregard these instructions in order to

avoid human injuries and environmental damages.

Operational warnings

Please do not disregard them to avoid damaging the

pump unit.

1. Introduction

Before starting to use the tool please read the

instruction manual carefully.

Use this tool exclusively for its determined use.

Mounting and assembly of connecting material with the help of this

tool must only be performed by specially trained personnel. The

minimum age is 16 years.

This instruction manual has to be carried along during the entire life

span of that tool.

The operator has

- to guaranty the availability of the instruction manual for the user and

- to make sure, that the user has read and understood the instruction

manual.

2. Labels

On the labels fixed on the housing of the tool you’ll find the type

specification, name of the manufacturer and the company logo. On the

opposite side of the housing you’ll find a label with technical data. The

serial number is on the hydraulic cylinder between the housing and the

head. On the head you’ll find a warning against crimping and cutting

hazards.

3. Warranty

If correct operation is guaranteed our warranty is 12 months from the

time of delivery.

4. Description of the electric-hydraulic universal unit

4.1. Description of the components

The electric-hydraulic universal unit is a hand held tool and consists of

the following components:

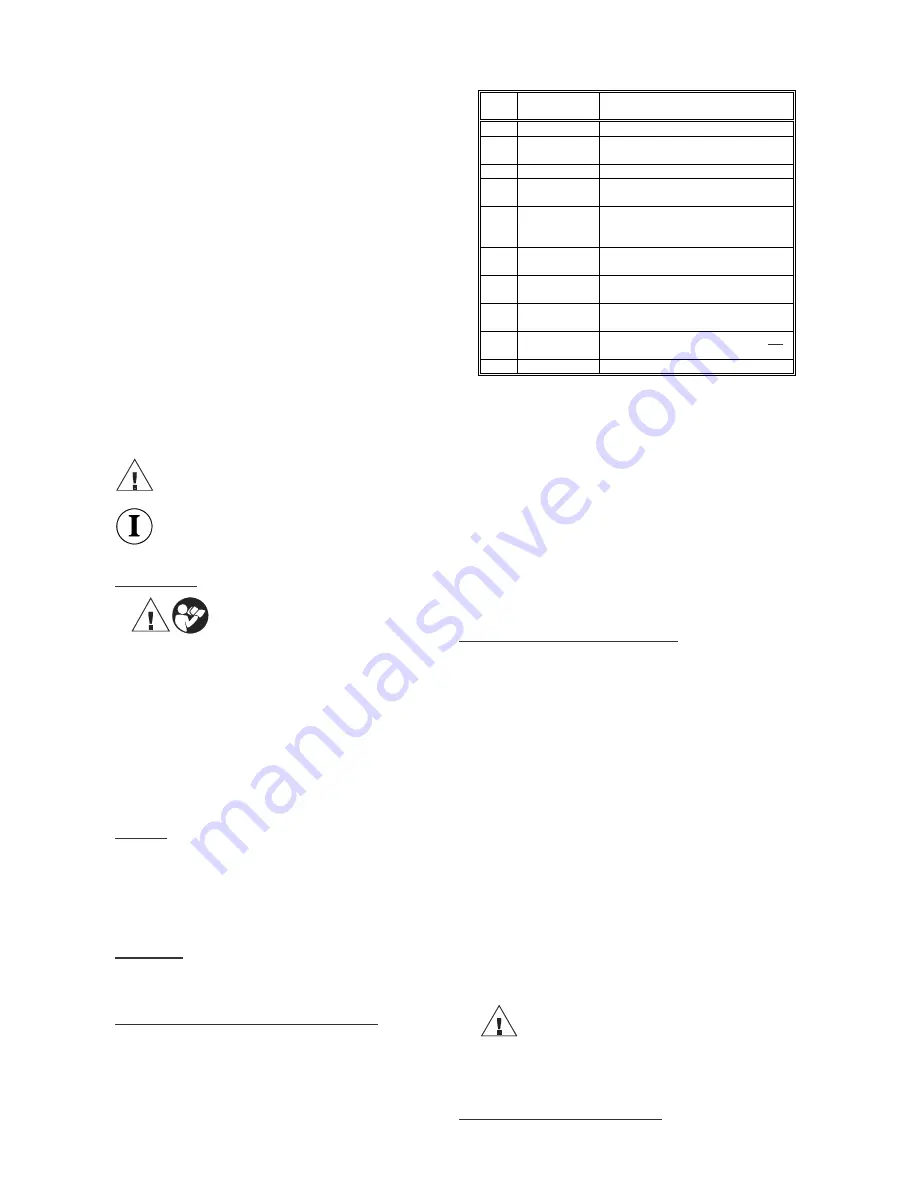

Table 1 (see Picture 1 page 2)

Pos.-

No.

Description Function

1

Trigger

switch to start working cycle

2

Retract button

button to retract the piston in case of

error or emergency

3

Latch

device to open/close the head

4

Adapter

Provides the use of different common

crimping dies

5

Housing

ergonomically formed plastic housing

for perfect handling with a detachable

lid

6

Locking pin

Adapter and cutting blades must be

locked with this pin prior to operation

7 Bending

protection

Protection device for mains cord to

prohibit conductor breakage

8

Ring

Loop to secure the tool and/or for

assembly purposes

9 Removable

hand guard

guard to protect the operating hand, not

for transportation

10

Dies (example) interchangeable 22 style crimping dies

4.2. Brief description of the important features of the unit

-

The hydraulic unit incorporates an automatic retraction which returns

the piston into its starting position when the required maximum force

is reached.

-

The unit is equipped with a special brake which stops the forward

motion of the piston when the trigger (Pos.-No. 1) is released.

-

The unit is equipped with a double piston pump which is characterised

by a rapid approach of the crimping/cutting dies (Pos.-No. 4+10, chart

2) towards the connector and a slow working motion.

-

The head can be smoothly turned by 360° around the longitudinal axis

in order to gain better access to tight corners and other difficult

working areas.

-

Compatability to all common crimping dies (60kN) by using special

adapters

-

Use of special dies and adapters including customer specific die

designs.

5. Remarks in respect of the determined use

Before starting any work on electrical appliances it must be safeguarded

that there are no live parts in the immediate assembly area of the user. Is

this not possible special precaution measures

1

for working near live parts

must be provided.

5.1. Operation of the unit

First the mains voltage must checked whether it matches with the

required tool voltage and then the mains plug must be plugged into the

socket. Since the unit is dooble insulated you can also use a not

grounded socket to connect the tool the te mains supply.

Then you have to select the right adapter for the type of dies (Pos.-No. 4,

10) you intend to use respectively the cutting blades. Afterwards the

head has to be opened by unhooking the latch (Pos.-No. 3 & Picture 2

Pos. A).

The adapters will be inserted into the universal head. Please follow

pictures 8-13 vicariously for all adapters and dies. Please make sure that

the locking pins (Pos.-No. 11) are always fully engaged.

After having completely closed the universal head the crimping/cutting

procedure is initiated by actuating the trigger (Pos.-No. 1 & Picture 2

Pos. C). The working cycle is defined by the closing motion of the

dies/blades.

Attention

The crimping process can be interrupted at any moment

by releasing the trigger.

In case of error or emergency the dies/blades can be returned into the

starting position by actuating the retract button (Pos.-No. 2 & Picture 2

Pos. B).

1

See EN 50110-1