36465D3-1 (08-06)

14

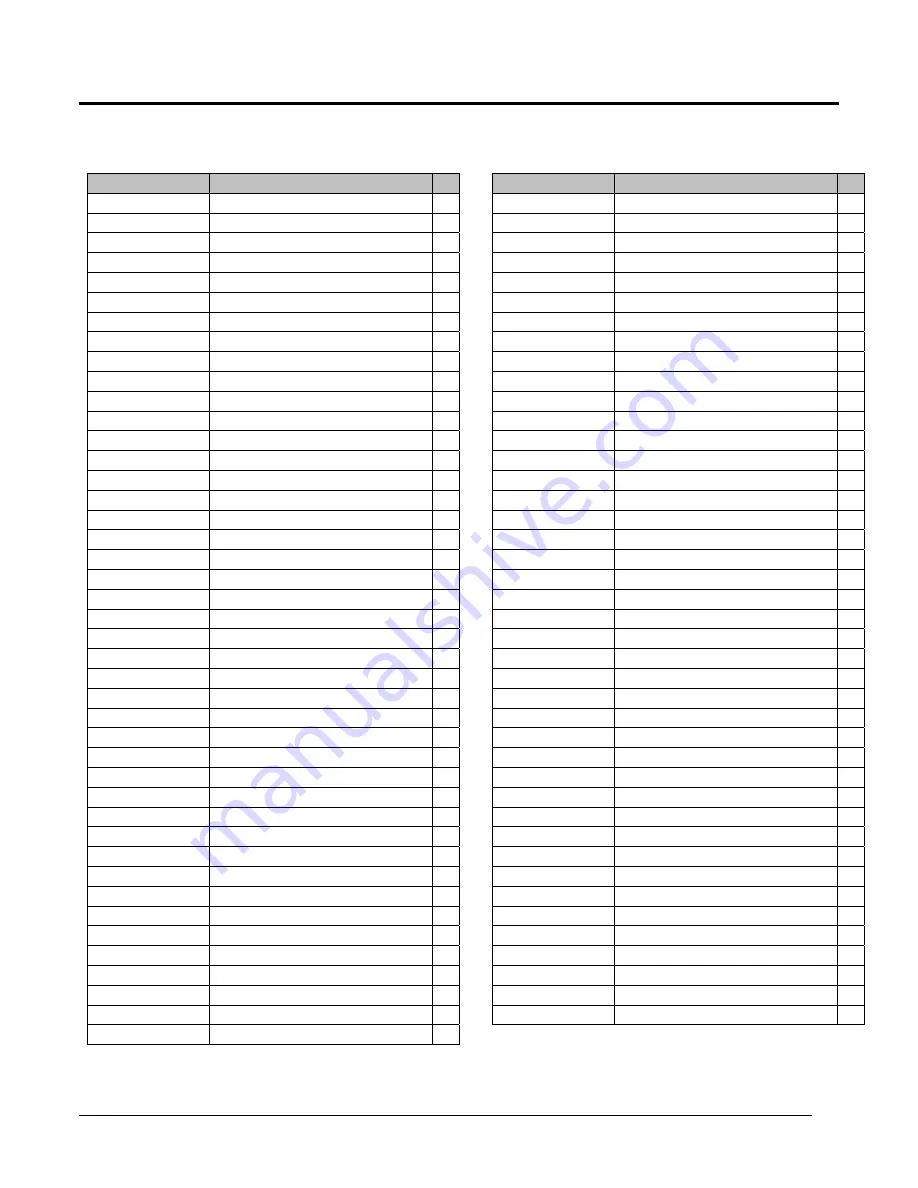

PARTS

LIST

36465D3-1

BASE GROUP

Part #

Description

Qty.

B-09.1

6-32 X 3/8 PHXSS

4

B-10

6-32 X 1/2 PHXSS

8

B-14

NUT 6-32 HEX SS

8

B-16.2

8-32 X 3/8 PHXSS

4

B-17.6

8-32 X 3/4PHX ZINC

4

B-18.02

NUT 8-32 NYLOK, ZINC

4

B-21

10-32 X 5/16 PHXSS

7

B-22

10-32 X 7/16 PHXSS

3

B-23

10-32 X 1/2 PHXSS

1

B-23.17

10 X 1/2 SELF TAP HEX

1

B-23.7

10-32 X 5/8 PHXSS

1

B-26.7

10-32 X 1 1/2 PHXZINC

2

B-28.01

NUT 10-32 HEX ZINC

7

B-29.1 WASHER,#10

SS

6

B-31.5

1/4-20 X 1/2 HEX CP

4

B-32

1/4-20 X 3/4 HEX HD CP

12

B-33.4

1/4-20 X 3 3/4 HEX CP

6

B-36.01

NUT 1/4-20 NYLOK ZINK

14

B-38.5

WASHER, 1/4 FLAT CP

20

B-42

WASHER 9/16 x 1 1/4 FLAT

6

B-45

NUT, 9/16-18 JAM NUT

1

C-02.3

CASTER 3 1/2"

2

C-03.3

CLAMP, HOSE 2 1/4 #32

4

C-04.1

COTTER, HAIRPIN 7/16-9/16

2

•

C-06

GASKET, BLOWER/ARLON 1/4"

2

C-07.3

GASKET,VAC SEAL EDGE BASE

1

C-23.8

WHEEL 10" - 1/2"BORE

2

C-30.2

GAUGE, PRESSURE 0-600 PSI

1

C-51

MUFFLER, FOAM EDGE

1

C-59

PUSHNUT FASTNER, 1/2 CAP

2

C-95

VELCRO, ONE WRAP STRAP 1/2" X

1

D-04

BUSHING 3/8 X 1/4 NPT BR.

2

D-15.2

45 ST ELBOW 1/4 NPT

3

D-17

90 ST ELBOW 1/4" NPT

4

D-18

90 ELBOW 1/4MPT x 1/4 MPT

1

D-20.015

ELBOW 90 1/4NPT X -6 SAE

1

D-43

NIPPLE, 1/4 HEX BRASS

1

D-44.03

NIPPLE, 1/4 X 2.5 BRASS

1

D-45.5

PLUG, 3/8" MPT BRASS

2

D-48.1

TEE,1/4 NPT BRASS

1

D-48.2

TEE,3/8 NPT BRASS

1

E-04.6

HOSE,1/4" PULSE W/SWVL

2

Part #

Description

Qty.

F-09

Q/C 1/4" PLUG BR SHUT OFF

1

G-37

VALVE,VAC SHUT OFF DUAL

1

J-45.6BLK

PMP MNT,DRLD 2 VAC FAN SILNCE B

1

K-17.4 CLAMP,NYLON

CABLE

1/4"

2

K-17.5

CLAMPS, NYLON CABLE 3/8

2

K-25.82 THERMOSTAT,

190

SPST 1

K-25.83 THERMOSTAT,

230

SPST 1

M-0563.85

BRACKET, MTR STARTER CAP 500PSI

1

M-0790.5

AXIL, ROD 1/2 EDGE ECONO

1

M-0791

AXIL, ROD 1/2 EDGE

1

M-0791.01

BRACKET,PRES RELFVAL EDGE

1

M-0791.01A

BRACKET,PRES RELFVAL 300PSI ED

1

M-0791.3

PIVOT, TUBE EDGE 3.400"

2

M-0792.01

PLATE,VAC MNT 2 VAC PARALL - QUI

1

M-0792.3 PLATE,HTR

MNT

EDGE

1

M-0792.4

PLATE,ASM HTR COVER EDGE 4 THE

1

M-0792.51 PLATE,FLAPPER

VALVE-EDGE

1

M-0792.6

PLATE, MUFFLER/PMP MOUNT COVE

1

M-0792.7

BRACKET, MANIFOLD DIV

1

M-31.17

STAND-OFF 5.7 EDGE 2.260”

6

M-72

SPACER, QUICK CONNECT

1

SE-06.7/24

HOSE,1/4 BLU 1/4NPTX1/8NP

1

SE-06.9/23

HOSE, -6SAE X 1/4NPT 21

1

SE-09.1/14A

HOSE,1/2GPH 14" 3/8NPTX3/8NPT

1

SE-09.1/25 HOSE,1/2"GPH

25"

3/8NPTX3/8NPT

1

SE-09.1/8A

HOSE,1/2GPH 8" 3/8NPTX3/8NPT

1

SE-12.5/5

HOSE,2" FLEX EXH 5"

1

SE-12.5/6

HOSE, 2" FLEX EXH 6"

1

SG-37

VALVE,DUAL FLPR MODI EDGE

1

SG-46.9

VALVE,PRESS RELF 500PSI MACH

1

SJ-02.3

EXCHG, CASTING COMP EDGE

1

SJ-40BLK101206210 BASE,BLK DRLD E2/3,PAR,QT,300PSI

1

SJ-45BLKCOV COVER,HTR

EDGE

1

SJ-46BLK

MANIFOLD,ASM VAC EDGE

1

SK-12.7

HTR,CRT 1750 120V COM EDG

1

SK-85K/BASE

HARNESS,BASE EDGE C2H CI C1PFV

1

•

SL-004.5

BLOWER,2STG 120 5.7W/PLUG

2

•

SL-28.500

PUMP, 500PSI CMP 110V

1

SM-0277.1

EXCHG,HT EDGE 110V 1750

1

SR-08/6 INSULATION,HTR

EDGE

1

•

RECOMMENDED STOCK ITEMS