TJXTREME

Installation and Operation Manual

PG 27/36

REV: A (5/8/2020)

9.5.

Install Horn & Compressor Sub-Assembly (TJ-101)

9.5.1.

Lift Horn and Compressor Sub-Assembly into place, by first inserting Flange Nuts from earlier step

through Bracket key slot holes, then slide Bracket forward until contacting Tank Bracket.

NOTE A:

If installing kit solo and Carriage Bolts are pushing up out of floor, temporarily re-install Guide

Plate (TJ-001) in place over Bolt heads to keep them from lifting during this step.

NOTE B:

Rear axle vent hose may need to be temporarily moved if it interferes with Bracket install.

9.5.2.

While holding Sub-Assembly in place, install

, as shown below. It is

recommended to apply medium-strength Loctite to fasteners.

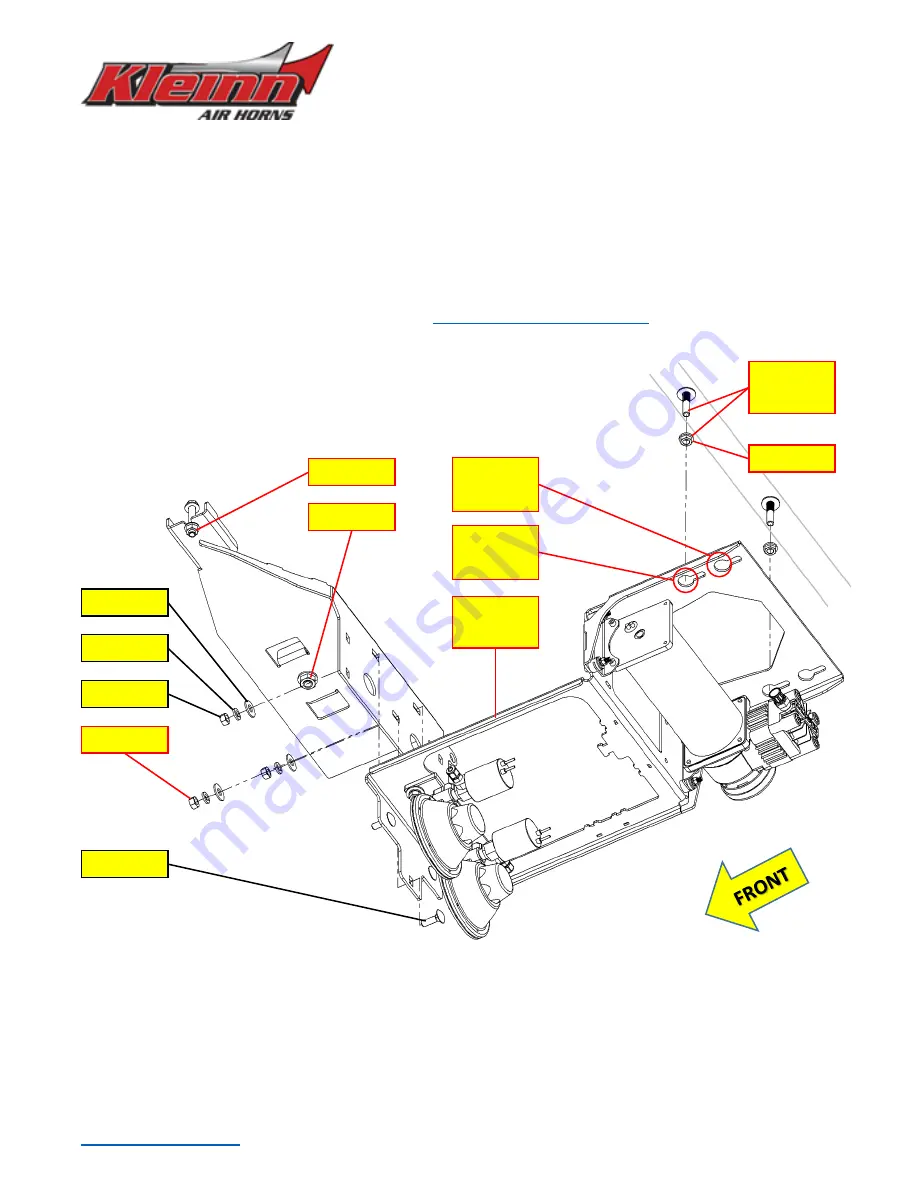

Figure 16

–

Installing Horn & Compressor Sub-Assembly, Exploded View (Air Tubing not Shown)

9.5.3.

Adjust Air Tank Bracket (TJ-201) laterally, to ensure Brackets align and provide at least 1/

4”

clearance

between all moving Brake Cables, Lines, Tubing, or Wiring.

Final torque fasteners, as shown above

.

CAUTION

: Do not over-torque Flange Nuts on Seat Bolts or Carriage Bolts; this may cause excessive

Bracket deformation or crushing of Rear Floor.

H10 (3)

H9 (3)

H11 (3)

H12 (3)

Previous

Step

75 in-lbs

50 in-lbs

TJ-101

Sub-Assy

12 ft-lbs

17 ft-lbs

Key Holes

for LJ

Key Holes

For TJ