GMTRK4

Installation and Operation Manual

PG 37/42

REV: BETA (4/4/2020)

10.

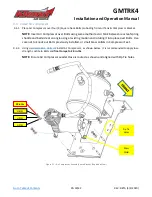

On-Vehicle Electrical Installation

CAUTION:

Follow all recommended safety precautions for working on vehicle’s electrical system;

consult vehicle

owner’s manual for further instruction.

10.1.

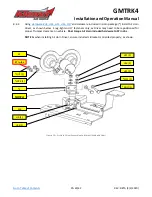

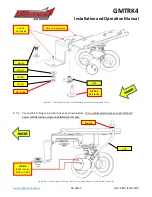

Relay and Fuse Diagram for Air Horn System

Figure 32

–

Suggested Ignition Relay Diagram for Air Horn System (Single 220 Horn Shown)

PRESSURE

SWITCH

(either wire

can go to

Relay or

Ignition)

AIR HORN

SOLENOID

(either wire

can be PWR

or GND)