RAMHD-230/734

Installation and Operation Manual

PG 16/41

REV: B (4/8/2021)

7.

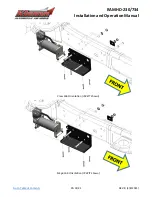

Bench Assembly Steps

Complete following steps off vehicle to facilitate final installation.

7.1

Unpack and Layout Kit Parts

Unpackage RAMHD-230/734KIT and verify all parts are included per above Parts List. Contact Kleinn support if

any questions arise.

It is recommended to layout and organize parts across a large work bench, or table in following order:

1.

Review train horn box and included hardware

2.

Review air compressor box and included hardware

3.

Review air tank box and included hardware

4.

Review kit mounting brackets and included hardware

5.

Review electrical/air fittings and included wiring and tubing

7.2

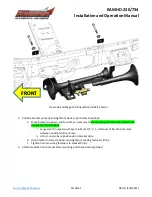

Disassemble Train Horn Kit

1.

Remove trumpets from drivers and set aside.

a.

Starting with largest trumpet, tightly grasp trumpet with both hands and unscrew counter

clockwise; trumpet may be very tight. Repeat on medium trumpet, then small.

i.

Drivers are identical and do NOT require marking Small, Medium, Large

b.

If necessary, clamp horn mounting plate to rigid table, in vise, or seek help to hold plate.

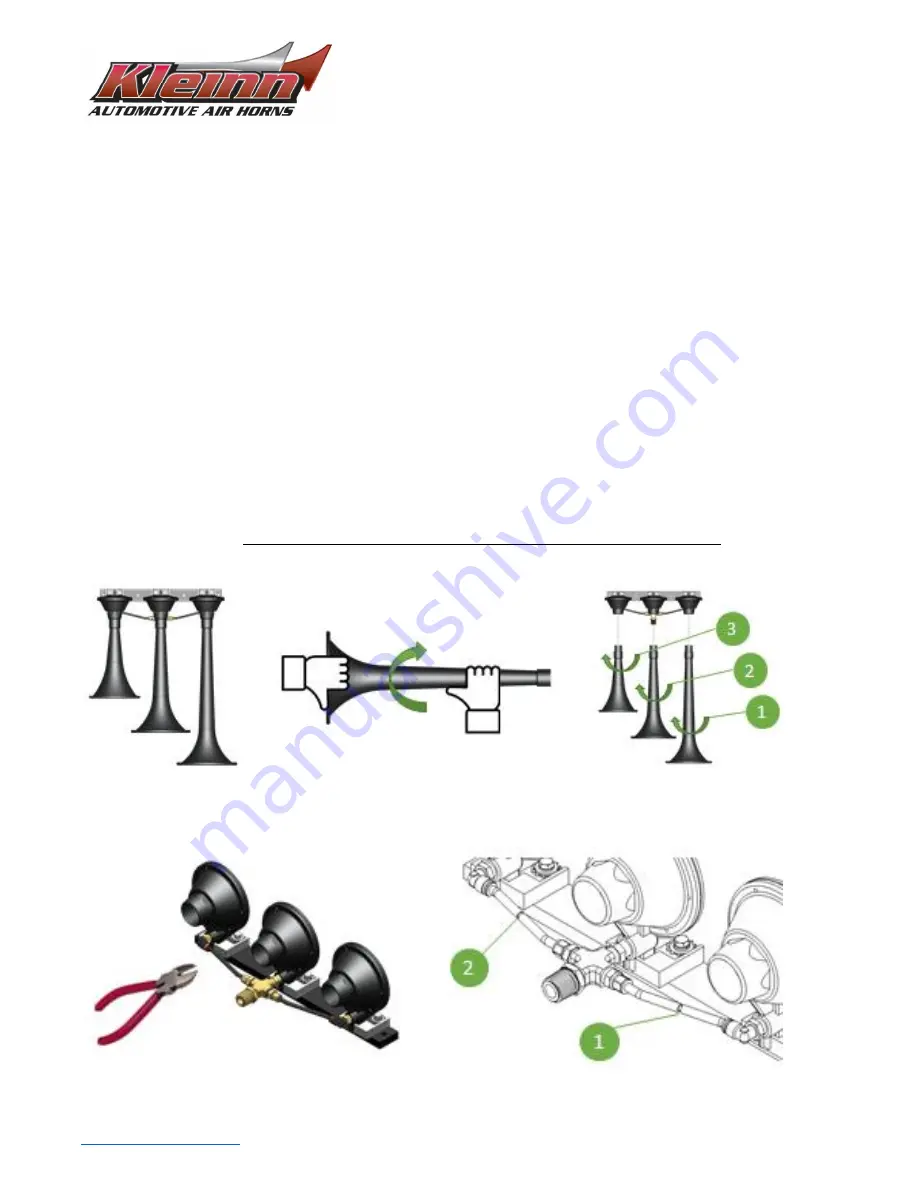

2.

Cut semi-rigid plastic air tubing between horns.

a.

Use sharp side/diagonal cutters, or equivalent to safely sever tubing.