trOubleshOOting

Possible problems could arise in the operation of your hydraulic pallet truck. Their probable cause(s) and

corrective action(s) follow:

Condition

Probable Causes

Corrective Action

Hydraulic unit does

not lift

Oil low in tank

Make sure there is no till leakage from valve and add oil.

Relief valve not seated properly or air in the

system

See “Cleaning Relief Valve" in this manual.

Defective pressure seal in main cylinder

Consult authorized service centre.

Relief valve not adjusted properly

Adjust valve by pressure adjustment screw

Once lifted truck

lowers by itself

Relief valve not seated properly

See “Cleaning Relief Valve" in this manual.

Defective pressure seal in main cylinder

Consult authorized service centre

Relief valve not adjusted properly

Adjust valve by pressure adjustment screw

Oil leakage

Consult authorized service centre

Fork does not lower

Cam chain broken

Replace cam chain.

UP-DOWn cam nut out of adjustment

Refer to “Adjusting UP-DOWn Cam" in this manual.

Broken fork rods and linkage

Consult authorized service centre

Cam chain lock-nut fallen off

Replace cam chain lock-nut

Lever does not set at

NEUTRAL position

Relief valve not adjusted properly

Adjust valve by pressure adjustment screw

Cleaning Relief Valve

Over time, relief valve may become clogged with debris and will not work properly.

To clean relief valve, flush the hydraulic system as follows:

Hold the UP/DOWn lever to the DOWn position and move the handles up and down several times.

Adjusting UP-DOWN Cam

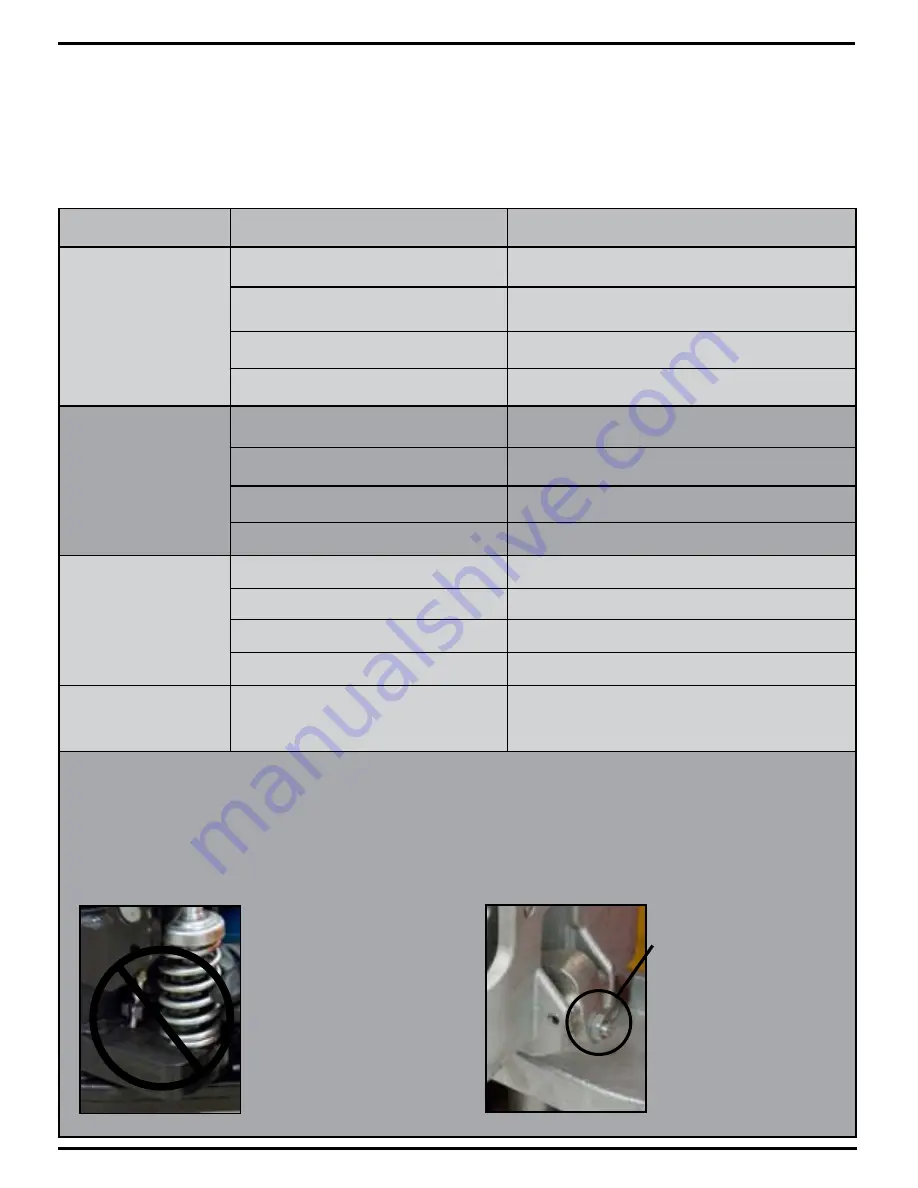

DO NOT

adjust the up/down

lever control using the lock

nut at the end of the handle

chain. If nylon locking threads

are removed from the screw

threads, rolling vibration will

cause the nut to unscrew and

fall off, leaving the up/down

lever unusable.

Use proper set screw

and lock nut adjustment

located on the side of the

pump. This feature was

designed to ease the pallet

truck adjustment.

Tools required are:

flat screwdriver and a

14mm wrench.