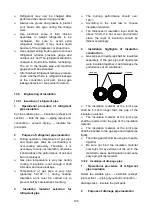

131

off and restart 30s later, if protection happened

3 times when fan motor restarts continuously,

the unit will stop and the LED will display the

failure.

When outdoor fan speed keeps too low (lower

than 100RPM) or too high (higher than

1500RPM) for 60s, the unit will stop and the

LED will display the failure. Malfunction is

cleared 30s later.

For A6 Duct& HESP Duct:

If a fault occurs on the air volume regulator or

the regulator enters protection mode, it sends

the error message CF and an instruction to

reduce fan speed to the master. The message

and the instruction can be inquired with the

remote controller or the wired controller. (Fault

and protection information are displayed for

one minute). After a fault occurs, the master

unit shows the error code E3 and the fault count

for one minute. If the fault occurs three times,

then the fan is unable to resolve the problem

independently. External shutdown by a remote

controller, wired controller, or central controller

must be used to clear the fan fault and fault

count. The fan runs normally for 5 minutes

while clearing fault count.

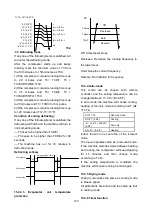

0:

No malfunction

1:P0 Overcurrent

2:Overpressure

3:

Overload

4:Overspeed

5:Startup malfunction

6:Lack of phase

7:DC voltage too low

8:Communication fault

9:Parameter fault

10:L3 Current limited

11:L5 Voltage limited

12:Target speed cannot be met during the

static pressure calculation process.

15.3.5 Inverter module protection

The Inverter module has a protection function

about current, voltage and temperature. If these

protections happen, the corresponding code

will display on indoor unit and the unit will stop

working.

15.3.6 Indoor fan delayed open function

When the unit starts up, the louver will be active

immediately and the indoor fan will open 7s

later.

If the unit runs in heating mode, the indoor fan

will be also controlled by anti-cold wind

function.

15.3.7 Compressor preheating functions

Preheating permitting condition:

If T4

<

3

℃

(37.4°F) and the machine connects

to power supply newly within 5 seconds or if T4

<

3

℃

(37.4°F) and compressor has stopped for

over 3 hours, the compressor heating cable will

work.

Preheating mode:

A weak current flow through the coil of

compressor from the wiring terminal of the

compressor, then the compressor is heated

without operation.

Preheating release condition:

If T4≥5

℃

(41°F) or the compressor starts

running, the preheating function will stop.

15.3.9 Condenser high temperature T3

protection

---55°C(131°F)<T3<60°C(140°F),

the

compressor frequency will decrease to the

lower level until to F1 and then runs at F1.If

T3<54°C(129.2°F), the compressor will keep

running at the current frequency.

---T3<52°C(125.6°F), the compressor will not

limit the frequency and resume to the former

frequency.

---T3>60°C(140°F) for 5 seconds, the

compressor will stop until T3<52°C(125.6°F).

15.3.10 Evaporator low temperature T2

protection

---T2<0°C(32°F), the compressor will stop and

restart when T2

≧

5°C(41°F).

---0°C(32°F)

≦

T2<4°C(39.2°F), the compressor

frequency will be limited and decreased to the

lower level

Summary of Contents for KDIP012-H2

Page 8: ...5 2 2 Part names of Indoor Outdoor units Cassette Units ...

Page 9: ...6 KDIR Duct Units ...

Page 10: ...7 KDIP Duct Units ...

Page 11: ...9 Ceiling floor Units ...

Page 12: ...10 HESP DUCT Units ...

Page 19: ...19 2 3 4 7 Outside Water Pump for Optional When Ceiling Installation ...

Page 31: ...33 KSIE024 H220 O KSIR036 H218 inch 37 2 16 1 31 9 40 6 26 5 15 9 ...

Page 34: ...36 Ceiling floor Units ...

Page 39: ...41 KTIR036 H2G1 KTIR048 H2G1 ...

Page 40: ...43 KUIR18 H2 KUIR24 H2 ...

Page 41: ...44 KFUF036 H2G1 KFUF048 H2G1 ...

Page 42: ...45 KFUF060 H2G1 ...

Page 43: ...46 KFUF036 H2G1 KFUF048 H2G1 ...

Page 44: ...47 KDIP090 H2 KDIP012 H2 KDIP018 H2 KDIP24 H2 ...

Page 69: ...74 6 2 Outdoor Unit KSIE018 H220 O KSIE024 H220 O ...

Page 70: ...75 KSIE009 H221 O KSIE012 H220 O ...

Page 71: ...77 KSIR036 H218 ...

Page 77: ...83 KDIR09 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 78: ...84 KDIR12 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 79: ...85 KDIR18 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 80: ...86 KDIR24 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 96: ...104 12 Field Wiring 9K 24K 36K 48K 60K ...

Page 97: ...105 ...

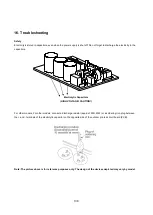

Page 147: ...155 P U P V ...

Page 148: ...156 P W P N ...

Page 181: ...191 4 Remove the evaporator fixing clamps to disassemble the evaporator Fixing clamps 1 screw ...

Page 188: ...221 5 Remove the four fixing screws of the fan motor then remove the motor 5 ...