106

13 Installation Details

13.1Location selection

13.1.1

Indoor unit location selection

The place shall easily support the indoor

unit’s weight.

The place can ensure the indoor unit

installation and inspection.

The place can ensure the indoor unit

horizontally installed.

The place shall allow easy water drainage.

The place shall easily connect with the

outdoor unit.

The place where air circulation in the room

should be good.

There should not be any heat source or

steam near the unit.

There should not be any oil gas near the unit

There should not be any corrosive gas near

the unit

There should not be any salty air neat the

unit

There should not be strong electromagnetic

wave near the unit

There should not be inflammable materials

or gas near the unit

There should not be strong voltage vibration.

13.1.2

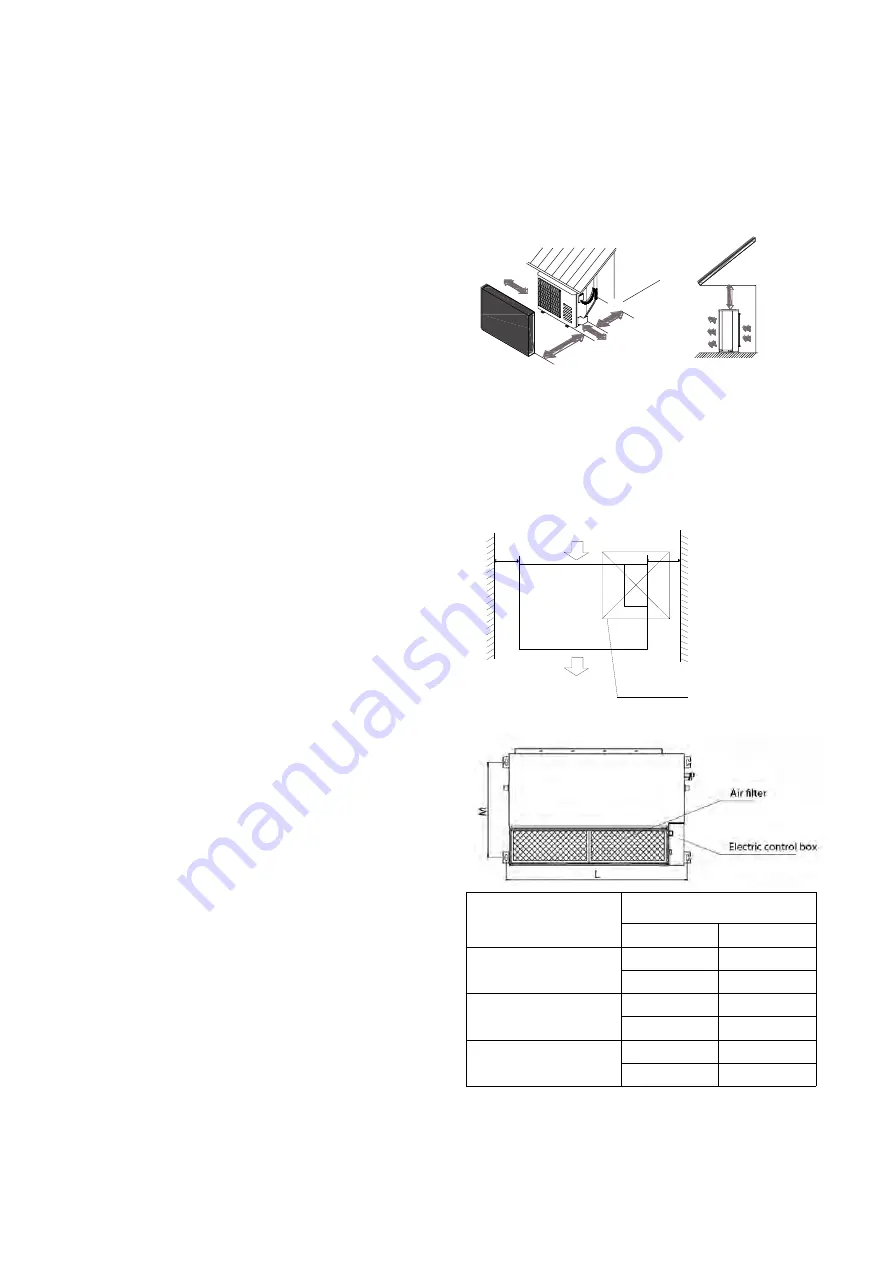

Outdoor unit location selection

The place shall easily support the outdoor

unit’s weight.

Locate the outdoor unit as close to indoor

unit as possible

The piping length and height drop cannot

exceed the allowable value.

The place where the noise, vibration and

outlet air do not disturb the neighbors.

There is enough room for installation and

maintenance.

The air outlet and the air inlet are not

impeded, and not face the strong wind.

It is easy to install the connecting pipes and

cables.

There is no danger of fire due to leakage of

inflammable gas.

It should be a dry and well ventilation place

The support should be flat and horizontal

Do not install the outdoor unit in a dirty or

severely polluted place, so as to avoid

blockage of the heat exchanger in the

outdoor unit.

If is built over the unit to prevent direct

sunlight, rain exposure, direct strong wend,

snow and other scraps accumulation, make

sure that heat radiation from the condenser

is not restricted.

More than 30cm/11.81in

More than 60cm/23.62in

More than 200cm/78.74in

More than 30cm/11.81in

More than

60cm/23.62in

(Service space

)

Fence

or

obst

acles

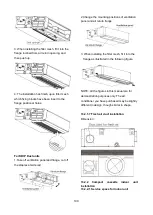

13.2 Indoor unit installation

13.2.1

KDIR

&

KDIP

Duct indoor

unit installation

13.2.1.1 Service space for indoor unit

A5/A6 Duct

200mm(7.87in) or more

300mm(11.81in) or more

600mmx600mm/23.62inx23.62in

Check orifice

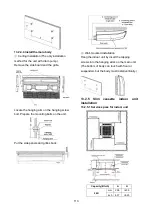

13.2.1.2 Bolt pitch

Model

Size of outline dimension

mounted plug

L

M

KDIR09-H2

KDIR12-H2

740

350

29.13

13.78

KDIR18-H2

960

350

37.80

13.78

KDIR24-H2

960

350

37.80

13.78

Summary of Contents for KDIP012-H2

Page 8: ...5 2 2 Part names of Indoor Outdoor units Cassette Units ...

Page 9: ...6 KDIR Duct Units ...

Page 10: ...7 KDIP Duct Units ...

Page 11: ...9 Ceiling floor Units ...

Page 12: ...10 HESP DUCT Units ...

Page 19: ...19 2 3 4 7 Outside Water Pump for Optional When Ceiling Installation ...

Page 31: ...33 KSIE024 H220 O KSIR036 H218 inch 37 2 16 1 31 9 40 6 26 5 15 9 ...

Page 34: ...36 Ceiling floor Units ...

Page 39: ...41 KTIR036 H2G1 KTIR048 H2G1 ...

Page 40: ...43 KUIR18 H2 KUIR24 H2 ...

Page 41: ...44 KFUF036 H2G1 KFUF048 H2G1 ...

Page 42: ...45 KFUF060 H2G1 ...

Page 43: ...46 KFUF036 H2G1 KFUF048 H2G1 ...

Page 44: ...47 KDIP090 H2 KDIP012 H2 KDIP018 H2 KDIP24 H2 ...

Page 69: ...74 6 2 Outdoor Unit KSIE018 H220 O KSIE024 H220 O ...

Page 70: ...75 KSIE009 H221 O KSIE012 H220 O ...

Page 71: ...77 KSIR036 H218 ...

Page 77: ...83 KDIR09 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 78: ...84 KDIR12 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 79: ...85 KDIR18 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 80: ...86 KDIR24 H2 Code 0 Code 1 Code 2 Code 3 Code 4 ...

Page 96: ...104 12 Field Wiring 9K 24K 36K 48K 60K ...

Page 97: ...105 ...

Page 147: ...155 P U P V ...

Page 148: ...156 P W P N ...

Page 181: ...191 4 Remove the evaporator fixing clamps to disassemble the evaporator Fixing clamps 1 screw ...

Page 188: ...221 5 Remove the four fixing screws of the fan motor then remove the motor 5 ...