8

explosion-proof roof fan

WPA-D-N /Ex

04.06.2019

Fan

Motor rate

[kW]

Current

[A]

Motor type

Cable

W1, W2

G-Y protective

cable W3, W4

WP-5-D-N/Ex

0,55

1,4

SKh 71-2B; 3x400V; 50 Hz

2720 r.p.m.; IMV1; BESEL

should be

selected

by User

H05V-K 1G6

WP-6-D-N/Ex

0,75

1,8

SKh 80-2A; 3x400V; 50 Hz;

2760 r.p.m.; IMV1; BESEL

WP-7-D-N/Ex

1,1

2,4

SKh80-2B; 3x400V; 50 Hz;

2780 r.p.m.; IMV1; BESEL

WP-8-D-N/Ex

1,5

3,5

SKh 90S-2; 3x400V; 50 Hz;

2850 r.p.m.; IMV1; INDUKTA

WP-9-D-N/Ex

2,2

4,7

SKg 90L-2; 3x400V; 50 Hz;

2860 r.p.m.; IMV1; INDUKTA

WP-10-D-N/Ex

4,0

7,5

SKg 112M-2; 3x400V; 50 Hz

2875 r.p.m.; IMV1; INDUKTA

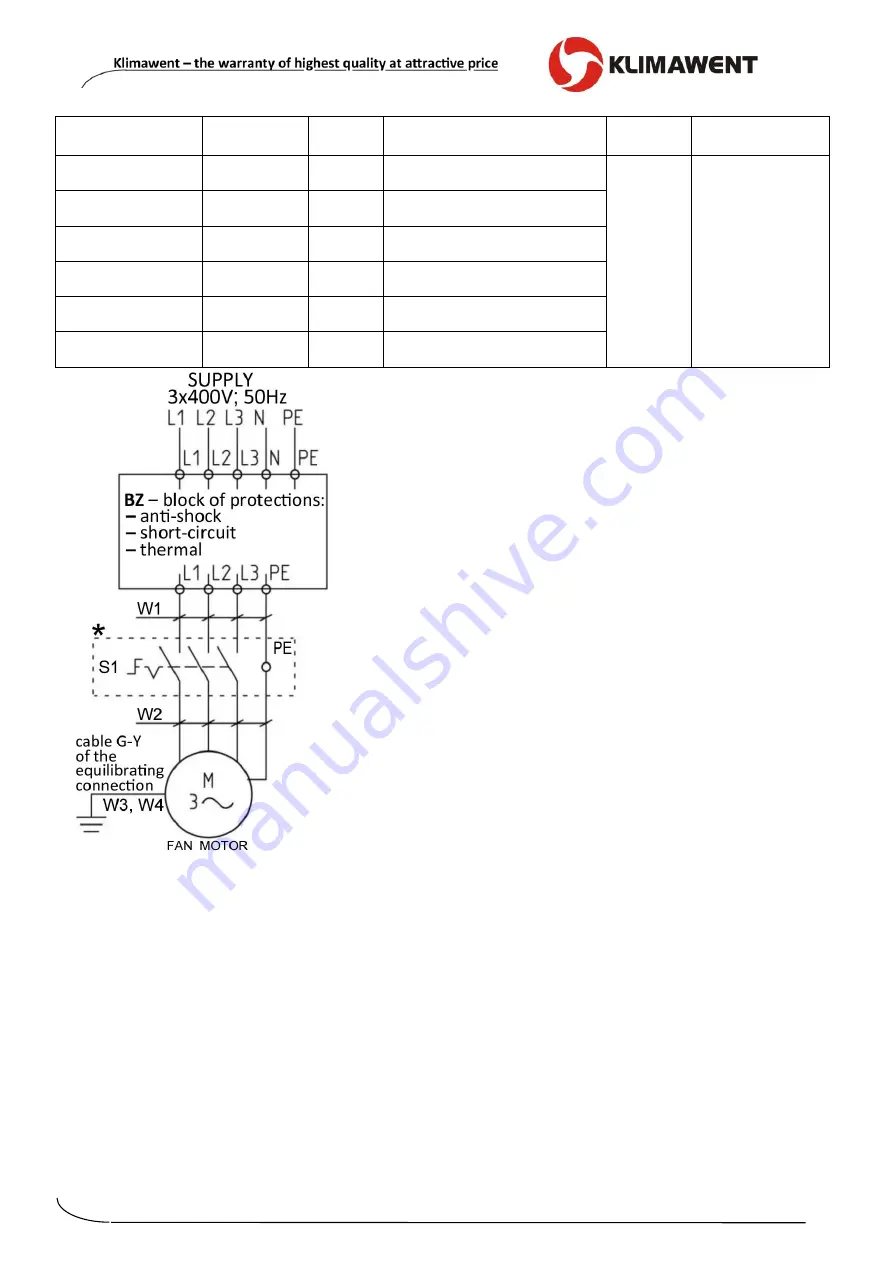

Caution

: The steel plate for current-equilibrating connections

– as in the Fig. No 1012-017078 of mechanical documentation

– referring the fans

WPA-10-D-N/Ex

;

WPA-10-E-N/Ex

.

Caution

:

1. Supply voltage:

3x400V

;

50Hz

2. Continuous work

S1

3. Ingress protection

IP56

4. Ambient temperature: -

20ºC

up to +

40ºC

5. Insulation class

F

6. To the fan housing connect the grounding cable

of length 400mm, ended with a

KOI

terminal.

7. Installations and devices for use in areas of

explosion risk

– should be executed according to

–

arrangements of the 2014/34/EC ATEX Directive,

–

valid regulations and standards.

*

S1

isolating switch

– in Ex execution. It is suggested to install

it near the fan. The application of the isolating switch is not

obligatory and depends on the decision of Investor.

Cables

W1

,

W2

have to be selected by Investor, with reference

to the fan motor rate, cable length, outline of the cable, voltage

drop.

W3

,

W4

are cables for local equilibrating connections of cross-

section 6mm

2

, length 300 mm, ended with adequately selected

eye terminals, designed for connection to the fan fitting pieces.

CAUTION

: The motor windings must be connected according

to the data on the nominal data plate of the motor and the

connection diagram (placed on the terminal box of the motor).

Fig. No. 4

– Connection diagram of the fan WPA-D-N/Ex