4

dust separator

EGO-2

;

EGO-4

11.10.2019

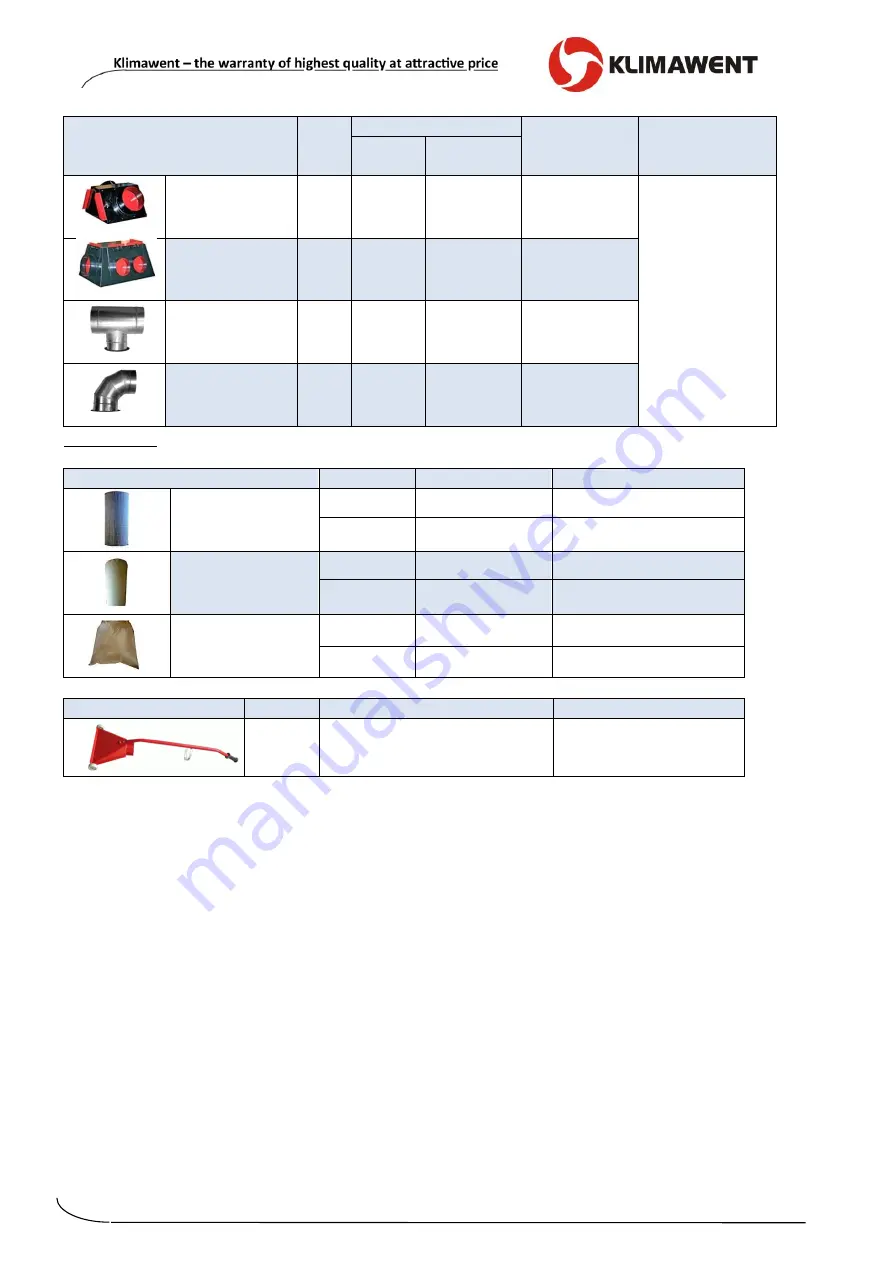

Table No.3

Sort of the connection fitting

piece

Type

Connections

Application

Remarks

Quantity

[pieces]

Diameter

[mm]

connection

head

G-2

2

125

EGO-2

Each fitting piece

can be equipped

with a suitable

reducer (see

catalogue card

“INSTALLATION

ELEMENTS”)

connection

head

G-4

2

2

125

160

EGO-4

connection T-

piece

TR-2

TR-4

2

2

160

200

EGO-2

EGO-4

connection

bend

K-2

K-4

1

1

160

200

EGO-2

EGO-4

Spare parts

Table No.4

Sort

Type

Weight

[kg]

Application

cartridge filter

CP-2

7,85

EGO-2-N/M

CP-4

9

EGO-4-N/M

filtration bag

WF-2

0,4

EGO-2-W/M

WF-4

0,5

EGO-4-W/M

collective waste

bag

T2

0,1

EGO-2

T4

0,1

EGO-4

Table No.5

Dust collecting nozzle

Type

Connection diameter

[mm]

slot length

[mm]

S-100/L

S-125/L

100

125

300

500

5. Structure and Function

Dust separator consists of a housing based on a trolley for a convenient displacement. To the

housing is fastened a motor with impeller (conveying the air with impurities). On the motor is

placed a motor protective switch with short-circuit- and overload protection and a power lead

cord ended with a plug.

Underneath the housing is located a waste bag, whereas above the housing is installed a bag

filter of filtration fabric (EGO-2 W/M, EGO-4 W/M) or cartridge filter (EGO-2 N/M, EGO-4 N/M)

Fig. No.1; Fig. No.2. Nearby, on the housing is placed a head with connections equipped

with slide dampers.

Instead of

the connection head can be installed an elbow Ø200 mm (EGO-4), elbow Ø160 mm

(EGO-2), or a T-

piece 2x Ø200 mm (EGO-4) a T-piece 2x Ø160 mm (EGO-2).

Elbows and T-pieces are not equipped with slide dampers.

The suction-inlets on the processing machines (or workplaces) have to be connected by hose

with the connections of the EGO dust separator.

To the terminations of hoses can be fastened a dust collecting nozzle to clean the workplace

after the finished work.

In the EGO dust separator proceeds separation of the impurities: heavy particles drop into the

waste bag, whereas light fraction deposit on the filter walls.