OPERATION AND MAINTENANCE MANUAL

DTR MCK v.2.4

PAGE

GDYNIA

MODULAR AIR HANDLING UNITS

MCKS, MCKH, MCKP

2017 EN

10/45

KLIMOR Spółka z ograniczon

ą

odpowiedzialno

ś

ci

ą

Sp.k., 81-035 Gdynia, ul. B. Krzywoustego 5

Fax: (+48 58) 783-98-88; Tel.: (+48 58) 783-99-99

Service -

Fax: (+48 58) 783-98-88; Tel.: (+48 58) 783-99-50/51 Mobile: (+48) 510 098 081

Information in this document is subject to change

email:

klimor@klimor.pl

-

office

serwis@klimor.pl

-

service

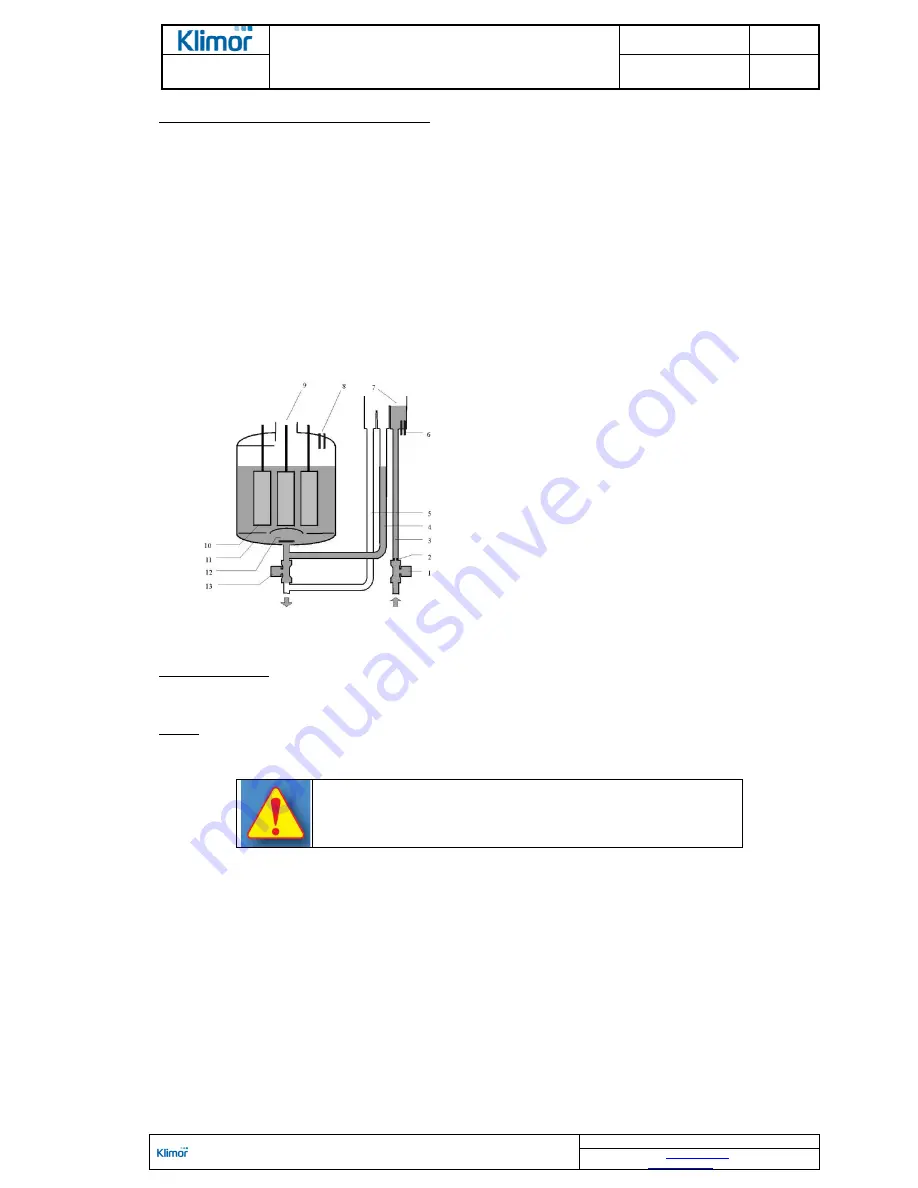

Humidifier with an electrical steam generator

The humidifiers with electrical steam generator use passage of current between electrodes immersed in water, to

heat up water and generate water steam. To enable passage of current between the electrodes, it is necessary to

use water containing mineral elements. The recommended composition of the water:

Required water parameters:

pH reaction: 7÷8.5

- conductivity: 350÷1250 uS/cm

- hardness: 100÷400 mg/l CaCo3

- iron and magnesium: 0,2 mg/l Fe+Mg

- silica: max 20 mg/l SiO2

- no organic contamination

- supply pressure: 1÷6 bar

- temperature: 1÷40°C

- water flow according to requirements of a particular generator

Higher concentration of mineral elements in water will lead to premature damage of electrodes and lower

concentration will cause drop of capacity of the steam generator

1. Supply solenoid valve

2. Flow limiter

3. Supply pipe

4. Filling pipe

5. Overflow pipe

6. Electrodes for conductivity measurement

7. Supply reservoir

8. Protection against excessive water level

9. Steam output

10. Electrodes

11. Cylinder

12. Water filters

13. Drain solenoid valve

Figure No. 7

Construction of the electrical water steam generator

Operation principle:

Once the supply valve is opened water flows through the supply reservoir into the cylinder. Once the cylinder is filled

the electrodes are heated and steam generation proceeds. Required steam generator capacity is achieved by setting

with the automatics control system an appropriate value of the current passing through the electrodes.

NOTE!

Type of a steam generator, amount and size of lances

–

all these parameters are determined individually for

a particular AHU and required amount of steam.

Method of starting up and operating humidifiers (water humidifiers, process

steam humidifiers and electrical steam generators) should be carried out

based on the instructions supplied by the humidifier manufacturer.

2.3.2.4 WC, DX cooling block

The task of this block is to lower the air temperature down to the temperature required according to the design data.

This task is accomplished by the water cooler, glycol cooler or direct expansion cooler (DX).

Standard cooler consists of a galvanized steel sheet casing and CuAl package with copper pipes and aluminum fins.

Manifolds and connectors are made of copper or steel.

The water and glycol exchanger is equipped with plugs: drain plug and venting plug. During assembly of hydraulic

system it is recommended to install drain and vent valves at the pipes leading to the heat exchanger.

When connecting coolers to the supplying system it is necessary to consider recommendations listed in the section 6.

A droplet separator is installed downstream the cooler to catch water drops.

In sectional coolers, in versions with double exchangers, the droplet separator is installed downstream the second

cooler.

Under the cooling block there is located a drip tray with a connector to drain off the condensate, led to the operational

side. In case of the AHU size 11 there is also provided another connector leading to the opposite side.

Drain traps are also provided and please make sure to install them in accordance with the guidelines listed in the

point 6.2.5

A cooler assembly and disassembly method in the AHU acc. to

Fig No. 3

.