OPERATION AND MAINTENANCE MANUAL

DTR MCK v.2.4

PAGE

GDYNIA

MODULAR AIR HANDLING UNITS

MCKS, MCKH, MCKP

2017 EN

15/45

KLIMOR Spółka z ograniczon

ą

odpowiedzialno

ś

ci

ą

Sp.k., 81-035 Gdynia, ul. B. Krzywoustego 5

Fax: (+48 58) 783-98-88; Tel.: (+48 58) 783-99-99

Service -

Fax: (+48 58) 783-98-88; Tel.: (+48 58) 783-99-50/51 Mobile: (+48) 510 098 081

Information in this document is subject to change

email:

klimor@klimor.pl

-

office

serwis@klimor.pl

-

service

Increasing resistance at the glycol cooler, caused by frosting, activates the pressure gauge and sends a signal to the

control system. The inverter lowers down frequency of the motor, which reduces the pump output and increases the

medium temperature in the system.

NOTE! As standard, the glycol heat exchanger block is delivered without the anti-frost system. Type of the system is

determined by an AHU or control system designer. Pressure system is recommended.

The pressure gauge setting should be 150% of the nominal air pressure drop at the heat exchanger. Nominal value

of the pressure drop is provided in the AHU technical data.

Settings of the inverters should be performed in line with instructions provided in section 2.3.2.7 (table no. 7 and No.

8)

,

however, data of the pumps motors should be applied from the table no. 10.

Wiring of inverters make according to their respective OMMs.

If the AHU has been delivered together with the Klimor control system, do not use these settings. Please use

information provided in corresponding control system OMMs.

Table no. 10

The parameters required for correct setting of the pump inverter

Symbol of glycol

system

Symbol of

pump

Min. motor

operation

frequency Fz min

[Hz]

Max motor

operation

frequency, FZ max

[Hz] [Hz]

Rated motor

output

[kW]

Rated motor

RPM

[rpm]

Rated motor

current

[A]

INST.GLKL.LE_HE 1

PUMP CM1-2

5

50

0,46

2790

2,2

INST.GLKL.LE_HE 2

PUMP CM1-2

5

50

0,46

2790

2,2

INST.GLKL.LE_HE 3

PUMP CM1-4

5

50

0,46

2790

2,2

INST.GLKL.LE_HE 4

PUMP CM3-3

5

50

0,46

2790

2,2

INST.GLKL.LE_HE 5

PUMP CM3-5

5

50

0,65

2790

3,1

INST.GLKL.LE_HE 6

PUMP CM5-6

5

50

1,2

2840

5,2

INST.GLKL.LE_HE 7

PUMP CM10-2

5

50

1,2

2840

5,2

INST.GLKL.LE_HE 8

PUMP CM10-2

5

50

1,2

2840

5,2

INST.GLKL.LE_HE 9

PUMP CM10-3

5

50

2,2

2895

8,15

INST.GLKL.LE_HE 10

PUMP CM10-3

5

50

2,2

2895

8,15

INST.GLKL.LE_HE 11

PUMP CM15-2

5

50

2,2

2895

8,15

Sets with the glycol system as standard are supplied in empty condition. Scope of pipeline assembly to be carried out

by Klimor in each case is determined while submitting an order. It has to be filled with glycol before starting the sys-

tem.

System filling procedure:

1.

Connect a manual or electrical pump to the #8 drain valve. Check opening of all ball valves in the system.

2.

Fill up the glycol gradually so that pressure at the #10 manometer does not exceed 0,25 MPa. The system is equipped with a safety valve

with the 0,3 MPa setting.

3.

Watch the breather once some amount of glycol is supplied. Releasing air indicates removing air from the system. Lack of air bubbles

means that you can fill some more glycol to the system. Repeat steps 2 and 3 till the system is filled with appropriate amount of glycol.

4.

During the filling procedure open the solenoid valve once in order to vent the bypass.

5.

The circulating pump before startup has to be primed with medium in line with the manufacturer's OMM documentation.

NOTE!

Strictly follow the instructions regarding glycol type and concentration stated in the AHU Data Sheet. Glycol type provided

depends on the AHU intended use. Ethylene glycol is dangerous for people and can be used only in facilities which have

received appropriate approval. In hygienic AHUs it is recommended to use propylene glycol.

Glycol concentration determines the freezing temperature

–

too low concentration value (and in turn

–

freezing tempera-

ture) can lead to permanent damage of the system and glycol leakage.

Table No. 11

Initial freezing temperature for ethylene and propylene glycol

Initial freezing temperature [

°

C]

-15

-20

-25

-35

Ethylene glycol concentration (% volume)

28

35

40

48

Initial freezing temperature [

°

C]

-15

-20

-25

-35

Propylene glycol concentration (% volume)

33

37

42

60

Glycol concentration stated in the table initiates the freezing process in a given temperature. The concentration in the sys-

tem for a given temperature should be higher in order to enable safe system operation.

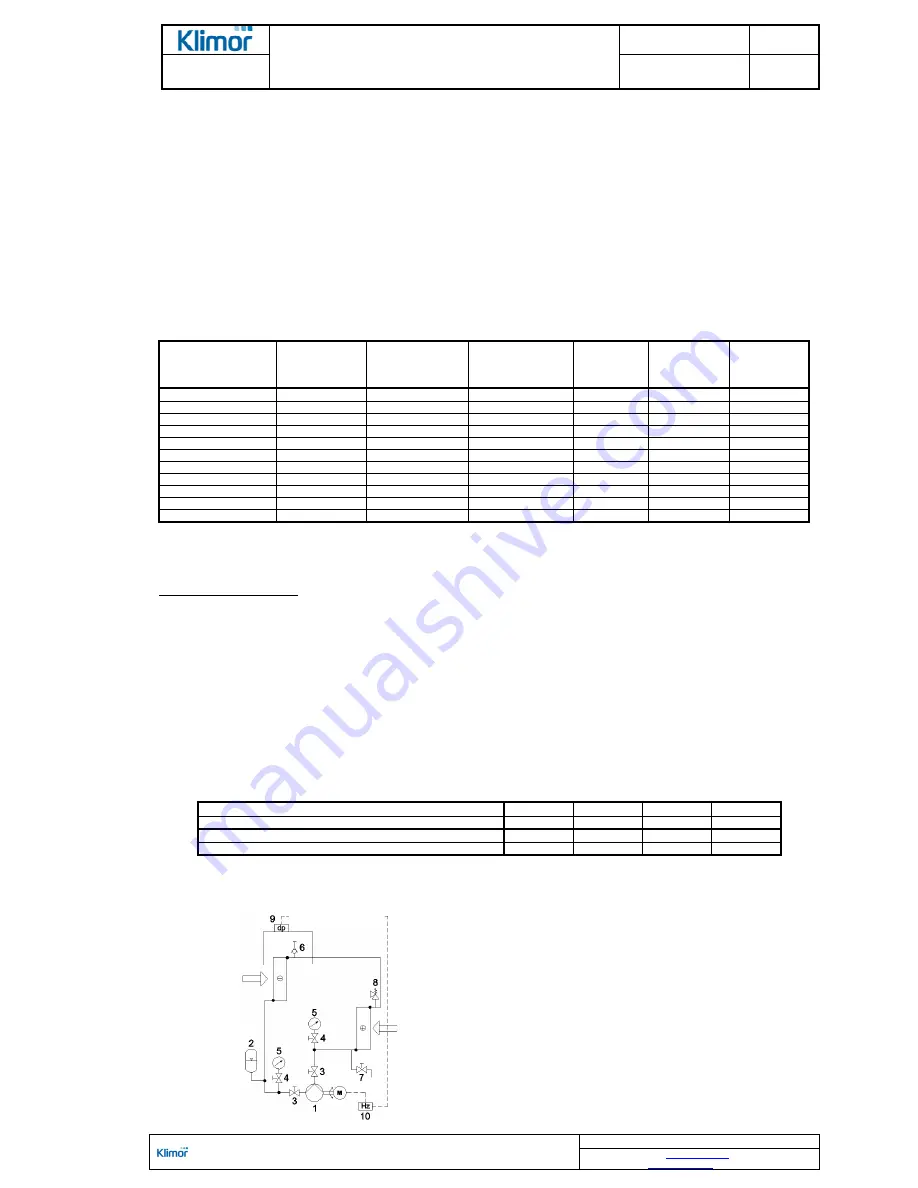

1. Circulation pump

2. Expansion vessel

3. Ball cut-off valve

4. Solenoid valve

5. Solenoid cut-off valve

6. Automatic breather

7. Manometer tap

8. Drain valve

9. Pressure gauge

10. Manometer

11. Safety valve

Figure No. 9

Glycol system diagram

automatic control