OPERATION AND MAINTENANCE MANUAL

DTR MCK v.2.4

PAGE

GDYNIA

MODULAR AIR HANDLING UNITS

MCKS, MCKH, MCKP

2017 EN

38/45

KLIMOR Spółka z ograniczon

ą

odpowiedzialno

ś

ci

ą

Sp.k., 81-035 Gdynia, ul. B. Krzywoustego 5

Fax: (+48 58) 783-98-88; Tel.: (+48 58) 783-99-99

Service -

Fax: (+48 58) 783-98-88; Tel.: (+48 58) 783-99-50/51 Mobile: (+48) 510 098 081

Information in this document is subject to change

email:

klimor@klimor.pl

-

office

serwis@klimor.pl

-

service

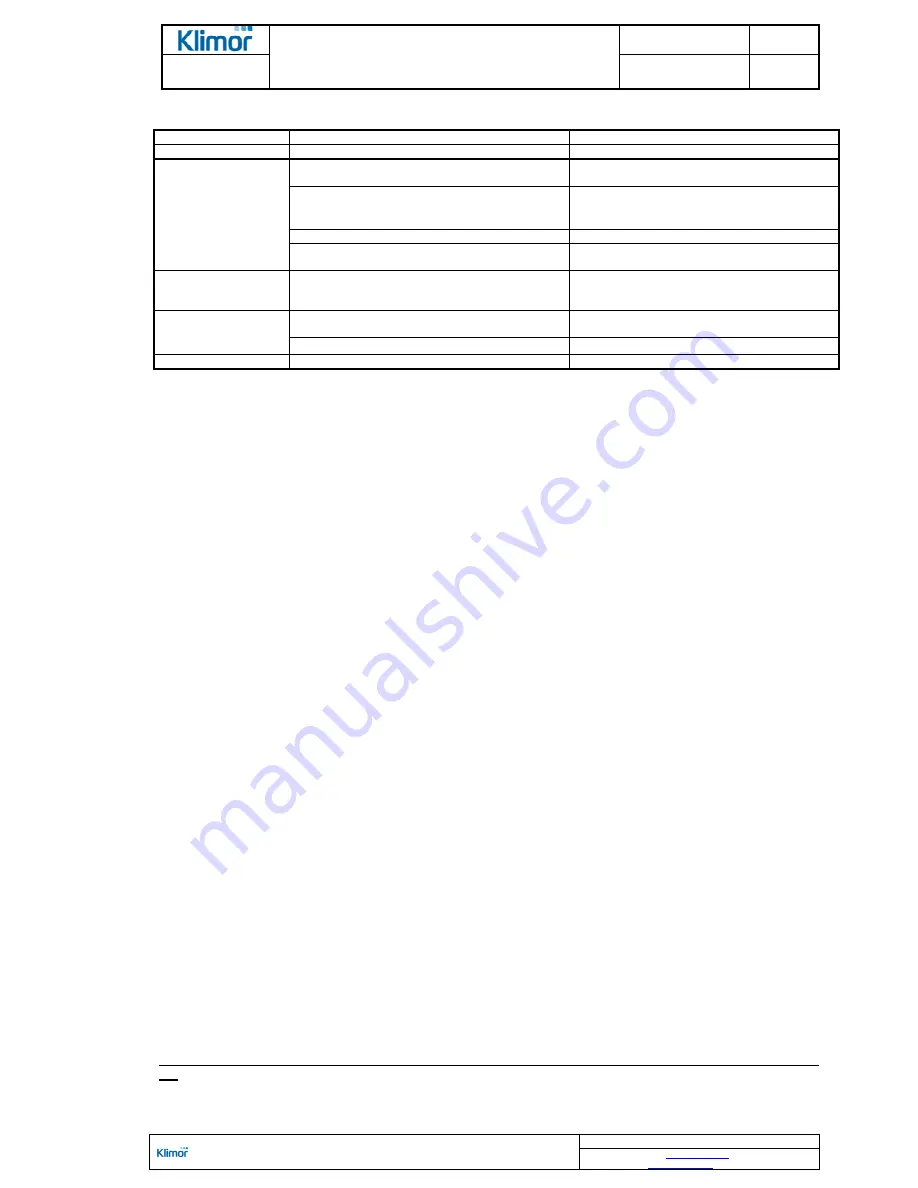

Table No. 22

List of the most common problems related to the CM and HPM cooling sets

Failure type

Cause

Remedy

1

2

3

Too high temperature

downstream the air

cooler

Incorrect adjustment of the thermostatic valve

Re-adjust

Not enough cooling medium delivered to the cooler

Contaminated filter

–

dehydrator at the cooler supply

(contamination) can be observed in the eyehole as a

different indicator color

Replace the filter with a new one

Faulty thermostatic valve

Replace with a new one

Oiled up air cooler

Remove oil from the cooler by reducing the over-

heating level at the thermostatic valve

The cooler compressor

turns on and off too of-

ten

Too low air stream: contaminated air filters

Clean or replace with a new one

Cooler frosting

Too low cooling medium evaporation temperature

Set an appropriate evaporation pressure using the

control valve (injection)

Too low air stream: contaminated air filters

Clean or replace with a new one

Escaping freon

Leakage at screwed or soldered connections

Locate the leakage and seal it properly.

9. PLANNING AND ASSEMBLY INDICATIONS

9.1 General indications

a)

If the device is located near the air intake or exhaust or duct system which may lead to autonomous cold air in-

flow into the device which is shut down, it is recommended to install at the internal air intake wall an additional air

damper to be closed during the shutdown.

b)

In case of water system supplying the heat exchangers with water it is necessary to install drain and vent valves,

thermometers and manometers near the devices.

c)

In case of heaters it is recommended to apply bypass of the control valve using the

∅

15 pipe with manual control

valve or adjustable orifice to allow residual cooling medium flow at very low temperatures in the heater when the

device is shut down.

d)

In case of AHU operation at temperatures below the cooling medium freezing point in the shutdown exchanger it

is necessary to drain the cooling medium. Once the water is drained it is necessary to blow the exchanger with

compressed air in order to remove any remaining fluid.

9.2 Indications for the water heaters

a)

It is recommended to use heating water with so called low parameters at 90/70°C.

b)

If the heaters are supplied with water at high parameters it is necessary to use high-pressure fittings (at least

1,6 MPa).

c)

Use counter flow unit operations.

9.3 Indications for the control system designer

Description of typical control systems can be found in separate materials.

9.4 Protecting the water heaters against freezing

It is recommended to apply the water heater protection systems to eliminate a risk of the cooling medium's tempera-

ture drop below its freezing point.

9.5 Protecting the electrical heaters against overheating

It is recommended to apply the system to control air flow through the electrical heater.

Enable turning off the electrical heater when the protecting thermostat is triggered and when the air flow drops.

9.6 Basic dependencies in operation of air conditioning and ventilation devices

a)

If the air supply and exhaust is connected mechanically, operation of air supply and exhaust fans is linked.

b)

Fans' starting and stopping time set at the inverter should be at least 30 seconds.

c)

If air flow through the AHU is stopped, supply of heating water should be stopped with the control valve at the

supply section. Only residual medium flow is allowed

Supplying the heaters without the air flow may lead to AHU damage. It is especially related to electrical heat-

ers.

d)

Operation of the humidifier and electrical heater is allowed only when air flows through the device.