Klindex

S.r.l.

Data ultimo aggiornamento: 6 / 08 / 2004

Pag. 13 di 33

INSTRUCTIONS

GB

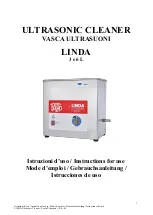

MACHINE STARTING UP

Make sure you have followed everything

described before.

Place resistance switch n°1 on location 1 and

wait for steam red pilot light to be on.

“Steam ready” pilot light switching correspond

to boiler pressure elevation of about 6 bar.

NOTE: simultaneous use of both resistances

allows reaching a faster working mode .

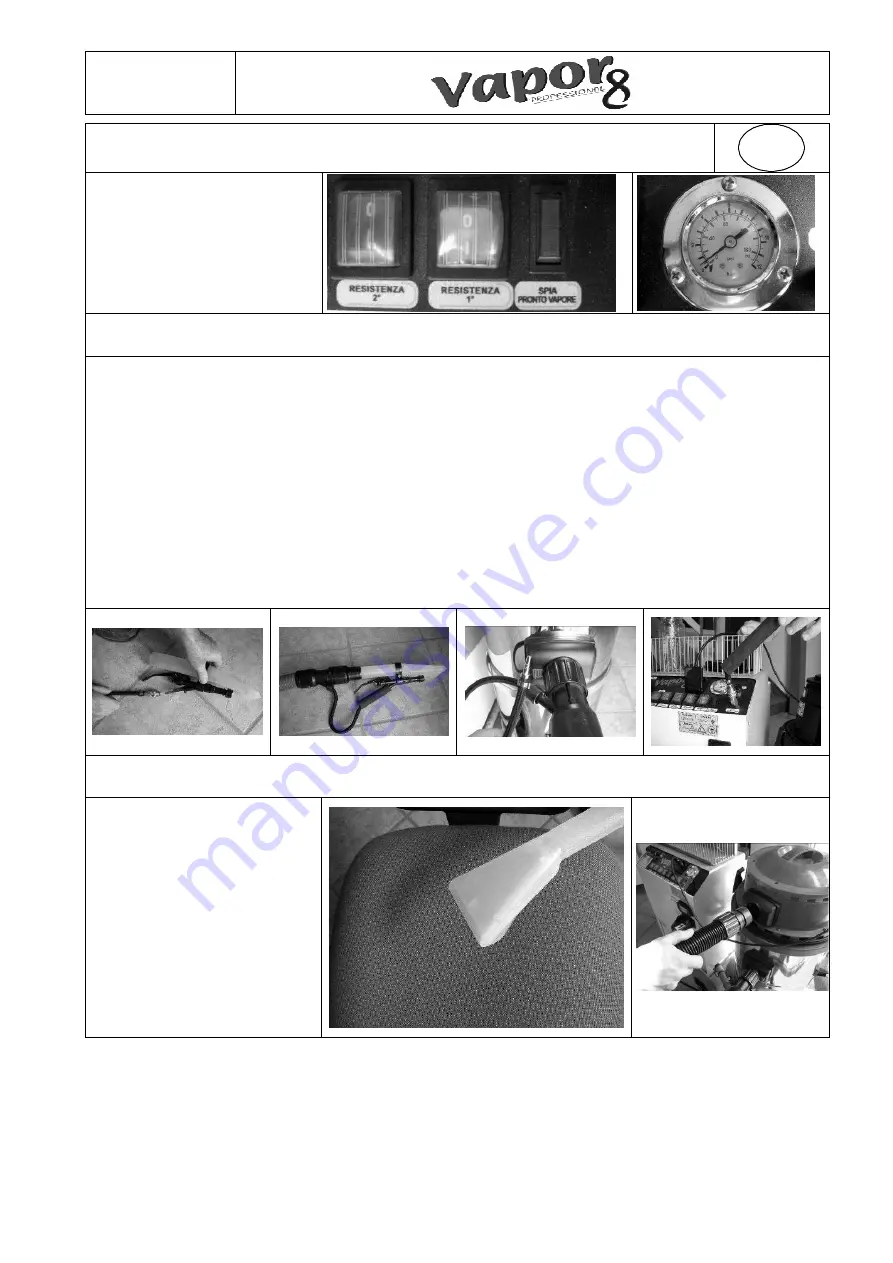

TAPESTRY CLEANING WITH HOT WATER INJECTION/EXTRACTION

It is possible to clean tapestry with hot water injection and the following extraction after switching the machine on as described above. The accessory to

be used is pictured below; moreover the right connection can be seen on pictures

Insert steam pipe into the location as pictured through fast coupling, covering metallic part with thermal sheath.

•

Insert vacuum pipe into the tool.

•

Insert vacuum pipe into the drum (do not insert into the filler on top of the machine).

•

Insert steam pipe, on the machine side, into the location as pictured through fast coupling, covering metallic part with thermal sheath.

Move hot water pump switch to position 1.

Hot water can be released by operating the lever placed on the accessory.

Hot water flow can be regulated by the knob placed on top of “presa acqua calda” as pictured.

Vacuum cleaner can be switched on by green switch.

NOTE: Hot air filler is located on top of the vacuum system, do not confuse it with vacuum filler located on the

drum.

WARNING: Do not turn boiling water jet towards any part of the body, use protective gloves.

USING HOT AIR

It is possible to use hot air jet produced by

vacuum system to dry tapestry after switching

the machine on as described above. Hot air

accessory and the attendant filler can be seen

on the pictures beside. After connecting the

accessory as indicated, hot air can be released

by moving GREEN switch named “accensione

aspiratore” on location 1.

NOTE: Hot air filler is located on

top of the vacuum system, do not

confuse with vacuum filler located

on the drum.

Summary of Contents for Vapor 8 PROFESSIONAL

Page 15: ...Klindex S r l Data ultimo aggiornamento 6 08 2004 Pag 15 di 33 ESPLOSO MACCHINA ...

Page 16: ...Klindex S r l Data ultimo aggiornamento 6 08 2004 Pag 16 di 33 ACCESSORI IN DOTAZIONE I ...

Page 18: ...Klindex S r l Data ultimo aggiornamento 6 08 2004 Pag 18 di 33 ACCESSOIRES DOTATION F ...

Page 23: ...Klindex S r l Data ultimo aggiornamento 6 08 2004 Pag 23 di 33 ACCESSORI OPTIONAL ...

Page 29: ...Klindex S r l Data ultimo aggiornamento 6 08 2004 Pag 29 di 33 VALVOLA DI SICUREZZA ...