Assembly and Repair Instructions

page 5 of 7

release 0

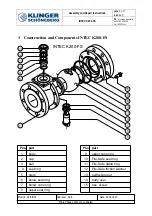

INTEC K200-FS

file:

Montage-Reparatur-

Anl INTEC K200-FS-

EN_100222.doc

Provide: Roth/BNi

Approval: Roth

Printed pages will not be updated

Date: 01.02.2010

In the case of valves stated as being oil- and grease-free assembly is performed without grease and

without other auxiliary substances.

Tighten hexagon screws (15) crosswise gradually until the seal is evenly pressed out and cap (2) is metallically

on block with body (1).

4.3

Assembling the Hand Lever

Push on hand lever, push on screw of the hand lever and tighten. Loosely tighten limit stop by means of the

screws. Bring ball into an exactly aligned open position. In this position press the limit stop against the manual

lever limit stop and tighten the screws of the limit stop. The limit stop is now perfectly aligned.

Starting from ISO flange F12 the adjustments of the manual lever limit stop are made using eccentric screws. The

eccentric screw is turned until it hits against the exactly aligned manual lever limit stop. Fix position of the screws

using the nut.

4.4

Function, Strength and Tightness Test

After assembling the ball valve it must be checked whether it can move freely and whether the ball can turn un-

hampered. Finally the ball valve must be subjected to a strength and tightness test in accordance with EN12266 -

1 Nr. P10 / P11 / P12.

4.5

Independent Conversion and Manufacture of Spare Parts

Conversion while changing the valve is only permissible after agreement and written declaration by the manufac-

turer. Original spare parts and accessories authorised by the manufacturer serve the purposes of safety.

If other spare parts are used and consequences result KLINGER SCHÖNEBERG GmbH shall not assume liabil-

ity.

4.6

Incorrect Operation

The operationally reliability of the valve is only guaranteed if it is used correctly in accordance with the operating

instructions for KLINGER SCHÖNEBERG ball valves. The limit value specified in the technical documentation

may under no circumstances be undercut.