Assembly and Repair Instructions

page 2 of 6

release 0

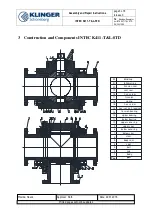

INTEC K411- T&L-STD

file:

Montage-Reparatur-

Anl INTE K411 T&L STD-

EN_22012016

Provide: Hauck

Approval: Roth

Printed pages will not be updated

Date: 22.01.2016

1

Validity

These Assembly and Repair Instructions are applicable to the type series listed below:

INTEC K411-T&L-STD

2

General Remarks

These Assembly and Repair Instructions are designed to provide assistance in assembling, servicing and repair-

ing the ball valve INTEC K411-T&L-STD.

The valves may only be dismantled and taken apart by skilled personnel acquainted with the assembly,

commissioning and operation of this product.

Trained personnel within the meaning of these Assembly and Repair Instructions are individuals who are able to

assess the work which they have been entrusted and to recognise possible risks in view of their special training,

their know-how and experience and their knowledge of the pertinent standards.

These instructions as well as the

Operating Instructions for KLINGER SCHÖNEBERG Ball Valves

must be

observed. KLINGER SCHÖNEBERG GmbH shall no assume no liability for damage or interruptions to operation

arising from incorrect handling or failure to observe these Repair Instructions.