Assembly and Repair Instructions

page 1 of 5

release 0

RK-Proball KH 1T M

file:

provide: BNi

approval:

printed pages will not be updated

date: 01.01.2006

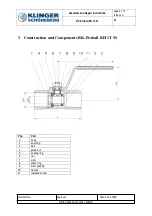

Assembly and Repair Instructions for KLINGER SCHÖNEBERG Ball Valves,

Type RK-Proball KH 1T M

Table of Contents

1

Validity ........................................................................................................................................................... 2

2

General Remarks........................................................................................................................................... 2

3

Construction and Components of the RK-Proball KH 1T M ........................................................................... 3

4

Assembly of the RK-Proball KH 1T M............................................................................................................ 4

4.1

Preparing for Assembly ........................................................................................................................ 4

4.2

Assembling the valve............................................................................................................................ 4

4.3

Function, Strength and Tightness Test................................................................................................. 4

4.4

Independent Conversion and Manufacture of Spare Parts................................................................... 4

4.5

Incorrect Operation............................................................................................................................... 4

5

Dismantling of the RK-Proball KH 1T M......................................................................................................... 5

5.1

Precautionary Measures....................................................................................................................... 5

5.2

Preparing for Dismantling..................................................................................................................... 5

5.3

Dismantling........................................................................................................................................... 5

5.4

Check of the Parts................................................................................................................................ 5