Introduction:

Thank you for selecting the Arc De Triomphe Desk Clock plan. Please

take ample time to thoroughly review the plan and assembly instruction materials before

beginning work on the clock assembly. If you should have any questions, concerns, or

comments, please feel free to contact Klockit (1-800-556-2548).

Required Components:

The components required for assembly can be purchased

separately through Klockit: You may use any 2-13/16” diameter non-alarm clock insert

(providing it has a 2-3/8” mounting diameter with a mounting depth of ¾” or less). 2-3/4”

diameter inserts can also be used providing that you also purchase as use the #15612

rubber gasket. Note that the plastic mount ring (included with 2-3/4” diameter inserts)

must be removed.

To assemble your desk clock, you will require the following from your local hardware

retailer: Yellow (Woodworking) Glue.

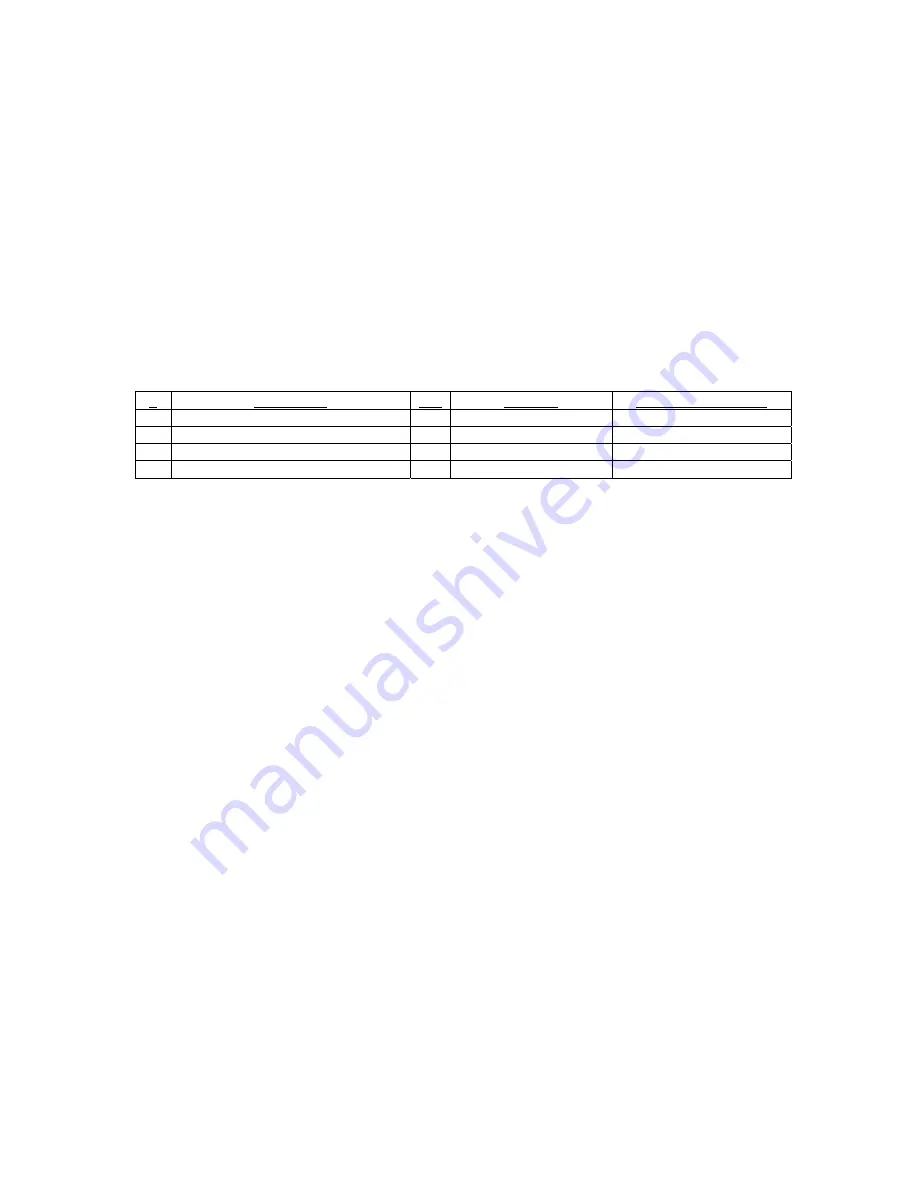

Parts Listing:

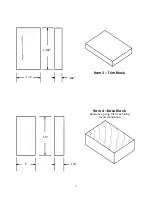

Note that finished dimensions are listed as L X W X Th.

#

Description

Qty

Material

Finished Dimensions

1 Case

Top/Bottom

Plate 2 Solid Wood

6-1/8” X 2-1/2” X ¾”

2

Clock Body

1

Solid Wood

5-15/16” X 4-5/8” X 1-¾”

3

Trim Block

2

Solid Wood

1-7/8” X 1-1/4” X 3/8”

4

Base Block

2

Solid Wood

1-3/4” X 1” X ½”

Before Machining:

Please note that we do not provide a cut list. Please take time to

review all wood parts and determine the lumber requirements to complete the Arc De

Triomphe Desk Clock (your local lumber dealer may be able to assist you with this). You

are welcome to select any lumber of your choice. Please note that you should always

figure excess lumber into your calculations (to account for saw cut thickness, possible

wood defects, etc). Laminated stock may be required for the clock body (Item 2).

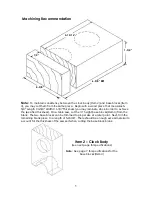

Machining Notes:

Recommended machinery to complete this project will include a

scroll saw, drill press, router, and table saw. The base will require a 3/8” radius cove bit,

while the movement housing (on the clock body) will require a 2-3/8” forstner bit (a shop-

made guide template can also be used in conjunction with a router to machine the 2-

3/8” diameter counter-bore). Note that a 2-5/8” diameter forstner bit may be used for

the lower arch (if available). Otherwise, the arch profile may be rough cut on a scroll

saw and then finish sanded with a drum sanding bit or spindle sander.

No matter what tools and/or accessories you should prefer to use to complete

machining, it is important to exercise proper shop safety (as per the instruction manuals

included with your power tools and accessories). Also make certain to wear the

recommended protective equipment (ear plugs, safety glasses, dust mask, etc.).

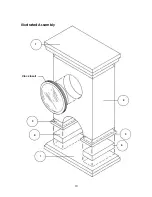

Upon completing machining of all wood parts, please refer to the assembly instructions

and illustration to assemble your clock. Please note that all illustrations are not drawn to

exact scale. Also note that the illustrated assembly and front/side elevation drawings

are not drawn to exact scale as well (in order to better illustrate certain assembly

procedures and proper mounting). Do not scale any of the drawings for dimensional

verification. If you should have any questions at any point prior to or during assembly,

please feel free to contact Klockit technical support (1-800-556-6474). Please allow 24

hours (max) for a response.

General Specifications:

The following specifications mirror Klockit’s engineering

specifications for kit products produced for Klockit retail sale.

Select a clear grained, kiln dried lumber of your choice.

2