19

HYDRAULIC CONNECTION

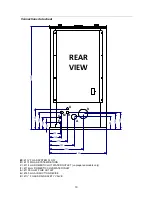

The hydraulic connections must be made in a rational way using the connections on the boiler

template. To ease connection of the pipes, we have prepared all hydraulic connections on the rear,

leaving space to make the connections easily.

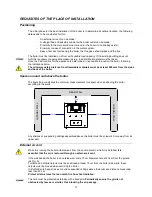

The boiler can be coupled to any other boiler already installed in the system; naturally it is

indispensable to insert the due safety devices and shut-offs according to the system used.

When installing the boiler, an anti-condensation mixer valve should be inserted between the

flow and return of the boiler's heating system.

N.B.: The boiler can be installed with closed expansion vessel, as it is equipped with fuel

loading stop device, safety manual rearm thermostat and acoustic alarm, which intervene if

temperatures are too high.

The boiler can be installed in the same room as another boiler as long has this has a sealed

chamber.

THE BOILER MUST BE INSTALLED EXCLUSIVELY BY QUALIFIED STAFF.

SCRUPULOUSLY

COMPLY WITH THAT STATED IN THIS GUIDE;

THE MANUFACTURER DECLINES ANY RESPONSIBILITY FOR DAMAGE CAUSED BY

INCORRECT ASSEMBLY.

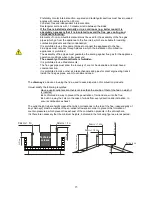

THE NETWORK WATER INLET PRESSURE MUST NEVER EXCEED 3 BAR; RECOMMENDED

WORK PRESSURE: 1.2 BAR.

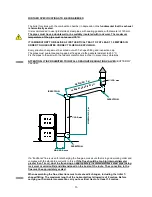

DO NOT PASS ELECTRIC CABLES IN THE IMMEDIATE VICINITY OF THE FLUE GAS PIPE,

UNLESS THEY ARE INSULATED WITH SUITABLE MATERIALS.

IF THE WATER HAS HARDNESS EXCEEDING 28 °f, AN ANTI-LIME SCALE DEVICE MUST BE

INSTALLED. THIS MUST BE SELECTED ON THE BASIS OF THE FEATURES OF THE WATER.

Summary of Contents for pellet boiler 24

Page 1: ...Pellet boiler PELLET BOILER 24 INSTALLATION USE AND MAINTENANCE USEFUL ADVICE User guide EN ...

Page 2: ......

Page 4: ...4 ...

Page 47: ...47 ...