4IN. x 36IN. BELT/6IN. DISC SANDER

OWNER’S MANUAL

2 of 7

TOOL USE SAFETY

•

Know your tool.

Learn the tool’s operation, application and

specific limitations.

•

Use clamps (not included) or other practical means to

secure and support the workpiece to a stable platform.

Holding the work by hand or against your body is unstable

and may lead to lose of control.

•

Do not force the tool. Use the correct tool for your applica

tion.

The correct tool will do the job better and more safely

when it is used for the application it was designed for.

•

Do not use the power tool with a malfunctioning power

switch.

Any tool that cannot be controlled with the power

switch is dangerous and must be repaired by a qualified

technician.

•

Avoid accidental start-up.

Make sure that the tool is in the

“OFF” position before plugging in.

•

Disconnect tool before making any adjustments, changing

accessories, or storing the tool.

•

Never leave tool running unattended.

Turn the power off

and do not leave tool until it comes to a complete stop.

•

Do not overreach.

Keep proper footing and balance.

•

Never stand on tool.

Serious injury could occur if tool is

tipped or if belt or disc are unintentionally contacted.

•

Keep hands away from moving parts and sanding surfaces.

•

Keep extension cords off the ground and away from water.

•

Use recommended accessories.

Accessories designed for

one tool may be hazardous when used on another. Use of

improper accessories may cause risk of injury to persons.

•

Turn machine off if it jams.

Belt jams when it digs too deeply

into workpiece. (Motor force keeps it stuck in the work.)

•

Support a workpiece

with miter gauge, belt platen or work

table.

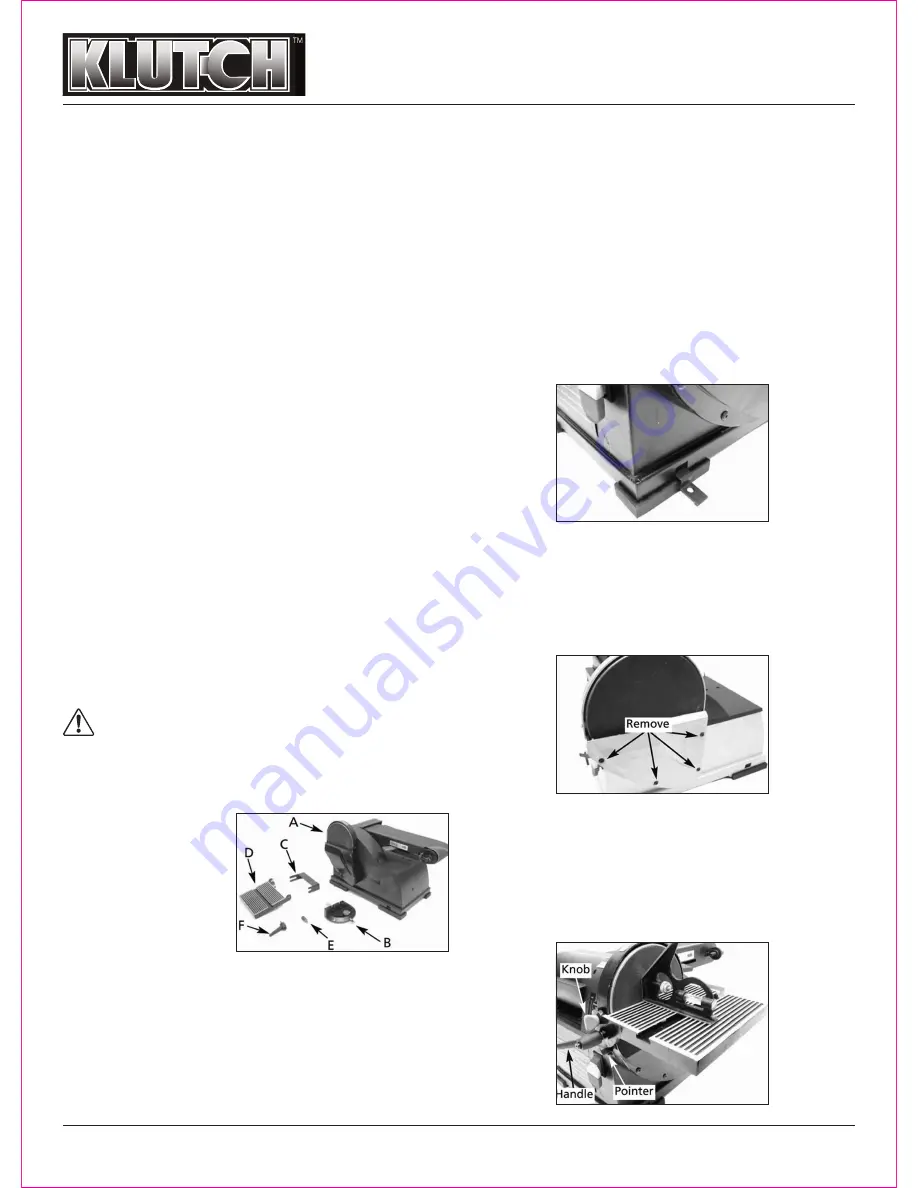

UNPACKAGING

WARNING:

Do not operate machine until completely

assembled. Do not operate machine until you have

completely read and understood this manual.

When unpacking, check for shipping damage and make sure

that the following parts are included:

A. Sander

B. Miter Gauge Assembly

C. Back stop

D. Table

E. Stud

F. Locking Handle

Not shown:

Abrasive Disc Knobs

4 Feet 4 Mounting Brackets

2 M6X16 Socket Head Bolts 4 M6X16 Hex Head Bolts

2 M6 Lock Washers 6 M6 Flat Washers

4 M6 Hex Nuts Hex Wrench and Open Wrench

4 M6 Hex 6 M6 flat washer 4 M6 hex nut

While assembling or adjusting your belt and disc sander, you

will need the following tools:

13mm Wrench

3 and 5mm Hex Wrenches

Combination Square

Phillips Screwdriver

ASSEMBLY INSTRUCTIONS

MOUNT SANDER

Make sure there is plenty of room for installing and allow for

table assembly and belt assembly in horizontal position.

• The sander must be bolted to a firm, level surface.

• Find the 4 rubber feet in the parts bag, press a foot onto

each corner of the base of the sander..

• Press-fit each Rubber Foot over the lip of the Base corner.

• The Sander can be installed on a workbench or a tool stand

using bolts, lock washers, hex nuts and mounting brackets.

ATTACH ABRASIVE DISC

• Remove the Disc Cover by loosening and removing the four

screws.

• Peel the protective paper from the back of the Abrasive Disc.

• Center the Abrasive Disc on to the Aluminum Disc and press

it on firmly and evenly.

• Replace the Disc Cover.

TABLE INSTALLATION

The included table is used with both the disc and belt.

• Position the Table on the Disc Guard and attach it using the

Knobs.

• Thread the Locking Handle through the Table and in to the

Disc Guard.

• Using a combination square, set the table perpendicular to

the Disc and secure in position. If necessary, set the Pointer

at 0º.