4IN. x 36IN. BELT/6IN. DISC SANDER

OWNER’S MANUAL

5 of 7

work being sanded. Keep end butted against back stop and

move work evenly across abrasive belt. Use extra caution

when finishing very thin pieces.

• Finishing curved edges: Finish outside curves on flat

por¬tion of abrasive belt. Finish inside curves on idler drum

por¬tion of abrasive belt.

• Finishing end grain: It is more convenient to finish ends of

long workpieces with the abrasive belt in a vertical position.

Position table on belt side of sander. Move work evenly

across abrasive belt. For accuracy, use miter gauge. Table

may be tilted for beveled work.

ABRASIVE DISC SANDING

• Abrasive disc sanding is well suited for finishing small flat

surfaces and convex edges.

• Move workpiece across down side (left) of abrasive disc.

Hold workpiece firmly with both hands; keep fingers away

from abrasive disc.

• Abrasive disc moves fastest and removes more material at

outer edge.

• For accuracy, use miter gauge.

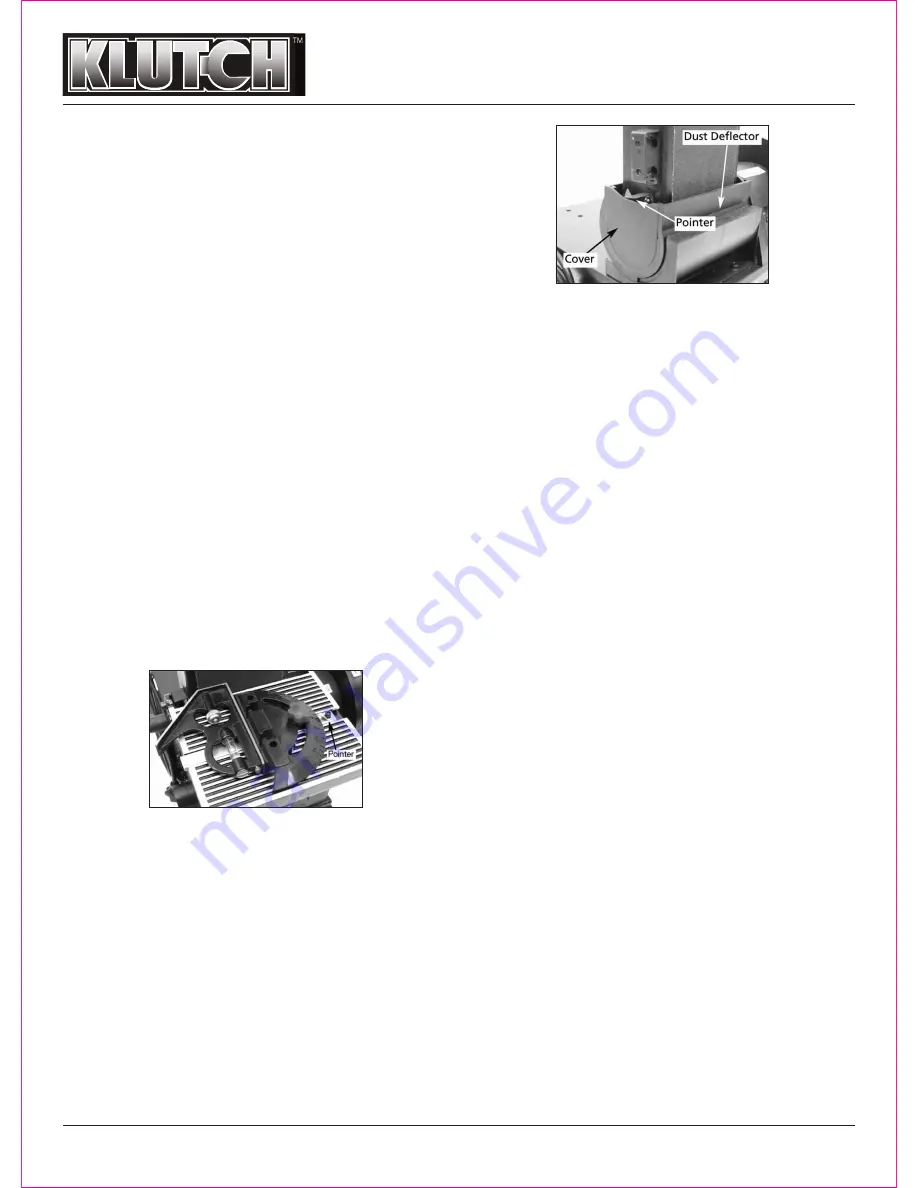

USING MITER GAUGE

• Use the miter gauge for securing the work and holding the

proper angle while sanding.

• Use a combination square to adjust miter gauge square to

belt /disc.

• Pointer should be at zero. Loosen screw and reposition

Pointer if necessary.

After setting miter gauge square to belt (disc), adjust to

desired angle by repositioning the miter gauge scale and

locking it into place with knob.

ABBRASIVE BELT REPLACEMENT

• Remove the Table Assembly and Back stop.

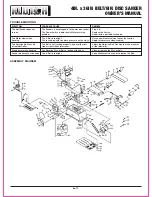

• Remove the Pointer, then slide the Side Cover up and out

from the Dust Deflector.

• Release the Belt tension by pushing the Tension Lever

toward the Idler Drum. Slide the old Belt off of the Drive and

Idler Drums.

• Slide the new Belt over the Drive and Idler Drums; Center the

Belt on the Drums.

• Push the Tension Lever towards the Drive Drum to tension

the Belt.

• Check the Tracking.

• Assemble in reverse order.

ABBRASIVEDISC REPLACEMENT

• Remove table assembly.

• Remove disc cover by loosening and removing four screws.

• Remove old abrasive disc by peeling it from the aluminum

disc.

Removing aluminum disc is not necessary.

• Clean aluminum disc if necessary. Select the desired

abrasive disc and apply to aluminum disc.

• Replace disc cover

MAINTENANCE REQUIREMENTS

•

Consult manual for specific maintaining and adjusting

procedures.

Or ask for qualified repair personnel. Service or

maintenance performed by untrained personnel could result

in a risk of injury.

•

Store tools out of reach of children and other untrained

persons.

Tools are dangerous in the hands of untrained

users.

•

Maintain tools with care.

Keep cutting tools sharp and

clean.Properly maintained tools with a sharp cutting edge are

less likely to bind and are easier to control. Do not use a

damaged tool. Tag damaged tools “Do Not Use” until

repaired.

•

Always unplug tool prior to inspection.

•

Keep tool lubricated and clean for safest operation.

•

Remove adjusting tools.

It is importantto ensure that any

adjusting tools are removed before switching machine on.

• K

eep all parts in working order.

Check to determine that the

guard or other parts will operate properly and perform their

intended function.

•

Use a dust extractor unit for eliminating wood chips.

The

airflow rate at the suction connector must be 65.6ft/s

(20m/s).

•

When servicing a tool, use only identical replacement

parts.

Use of unauthorized parts or failure to follow mainte-

nance instructions may create a risk of electric shock or

injury.

•

Check for damaged parts.

Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a tool’s operation.

•

A guard or other part that is damaged should be properly

repaired or replaced.

Do not perform makeshift repairs. (Use

parts list provided to order replacement parts.)