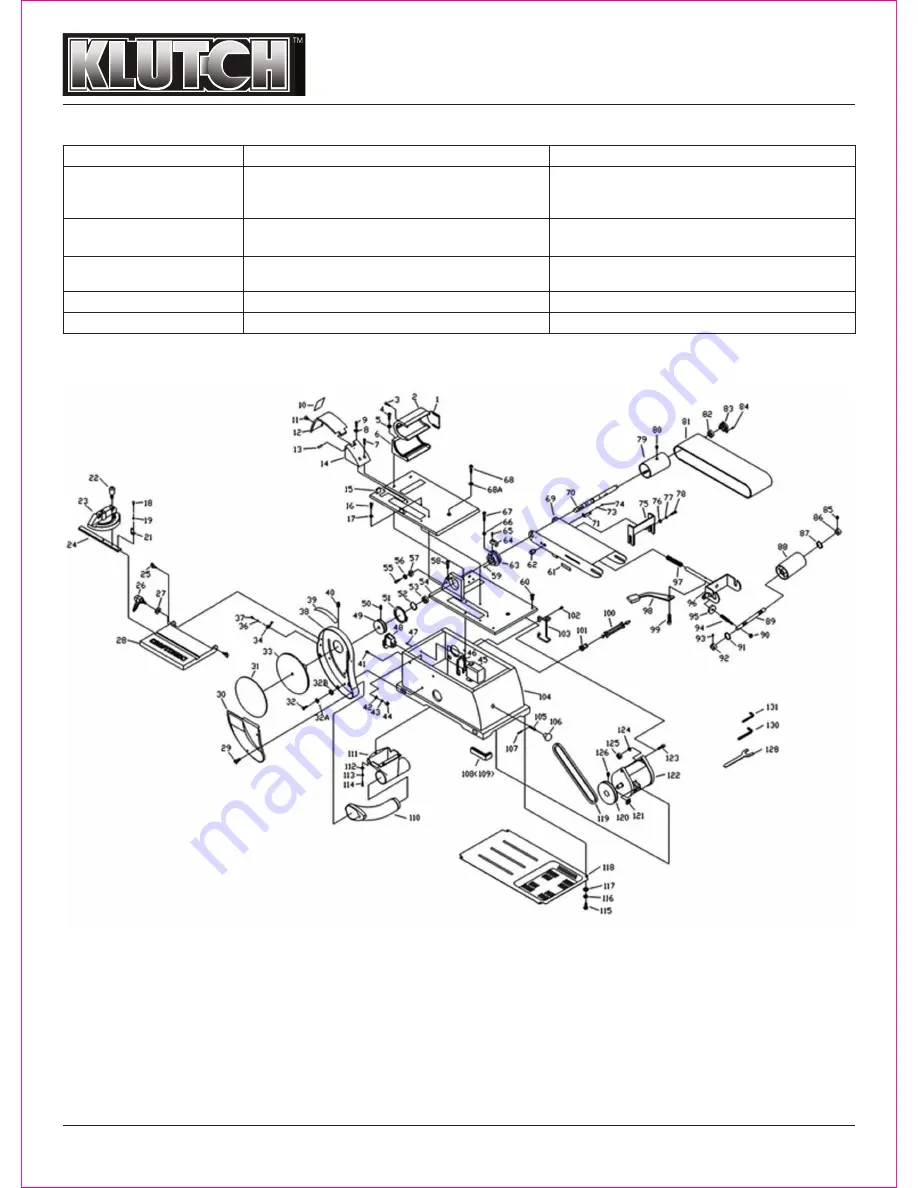

4IN. x 36IN. BELT/6IN. DISC SANDER

OWNER’S MANUAL

6 of 7

TROUBLE SHOOTING

ASSEMBLY DIAGRAM

SYMPTOM

The Belt Sander does not

turn on.

The Motor slows when

Sanding.

The Abrasive Belt runs off

of theIdler Roller.

Wood burns while Sanding.

Sander makes excessive noise.

PROBABLE CAUSE

The Sanders is not plugged in to the electrical outlet.

The Power Switch is defective/a Motor or wiring

problem.

The V-Belt is too tight.

You’re sanding with too much pressure on the stock.

The Belt is not tracking properly, it goes either left

side or right side of idler roller.

The Abrasive Disc or Belt is loaded with debris.

The V-Belt is too tight.

REMEDY

Plug it in.

Replace the Switch.

Repair with a qualified technician.

Have a qualified technician loosen the tension.

Apply less pressure when sanding.

Adjust the Abrasive Belt Tracking to make at center

of the idler roller.

Clean or replace the Disc or Belt.

A qualified technician needs to loosen the Belt.