EN - 7

Device-specific additional instructions for nailer

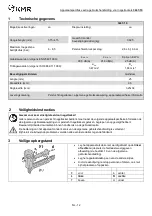

3447-10

4

Filling the magazine

•

Ensure that nailer and fasteners are compatible (Chap. 1) with

each other.

•

Check fasteners for proper condition.

•

Press the latch button 1 and push the magazine cover 2 to the

rear. Insert the shaft nails into the magazine 3 with the red side

facing upwards. Then push the magazine cover 2 forward.

5

Adjusting drive-in depth

•

Reduce pneumatic operating pressure as far as possible to minimize blowback,

noise and air consumption (see General operating instructions).

Mechanical adjustment of drive-in depth:

•

Disconnect nailer from pneumatic supply.

•

Turn adjustment ring ('

qu

' in Fig. 1 right) with supplied hexagon screwdriver or

with pin (max. diameter 4.5 mm (0.18 in)).

Each turn from hole to hole equals a height change of 0.2 mm (0.01 in); max.

possible height change is 6 mm (0.24 in).

Turning to the right increases the drive-in depth, turning to the left decreases it.

•

Check current setting: It equals the distance between the screw head and the

flange's contact surface. (max. distance = 6 mm; greatest drive-in depth)

6

EU Declaration of conformity

The BeA GmbH, manufacturer or importer, address as on cover sheet, declares under sole responsibility this product's conformity with all

relevant provisions of the EU Machine Directive 2006/42/EG. The following standards are applied:

EN ISO 12100:2010 (Machine safety); ISO 11148-13:2017-11 (Hand-held non-el. machines - Fastener driving tools);

EN 12549:1999+A1:2008 (Noise measuring for driving tools); ISO 8662 (Vibrations at driving tools).

------------------------------------------

-----------------------------------------------------------

Dr. Jörg Dalhöfer, CEO

Joachim Bauer, Documentation responsible

Summary of Contents for 3447-10

Page 3: ...3 ...