Servicing

Diaphragm pump N87.9 EX

30

Translation of Original Operation and Installation Instruction, english, KNF 323252 04/21

3. Properly dispose of the replaced structured diaphragm and valve

plates/seals.

To ensure the required gas tightness of the pump following servic-

ing, a leak test is to be performed.

WARNING

Risk of explosion from leaks

à

Before recommissioning the pump, check the

pump heads and pneumatic connections for

leaks. Leaks may lead to a risk of explosion.

WARNING

Risk of injury and poisoning from leaks

à

Before recommissioning the pump, check the

pump heads and pneumatic connections for

leaks. Leaks may lead to poisoning, chemical

burns or similar injuries.

Before recommissioning, observe the applicable standards, guide-

lines, regulations and technical standards at the electrical connec-

tion.

9.4 Changing the structured diaphragm and valve plates/

seals (S_-/A_ design based on project)

Requirements

à

Disconnect the motor from mains and ensure that it is voltage-free.

à

Clean the pump and free the pump of hazardous materials.

Spare parts

Spare part*

Item designation**

Number per pump

head

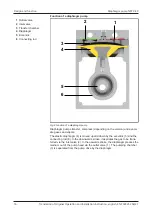

Structured diaphragm

(7) in Fig. 8

1

Valve plates/seals

(12) in Fig. 8

2

Tab.17 *According to spare parts list, Chapter 11.1 Spare parts

Tool and material

Quantity

Tool/material

1

TORX® screwdriver T20

1

Phillips screwdriver

Thread locker

(Loctite 222 or comparable product)

1

Felt-tip pen

Tab.18

Information on the procedure

à

Always replace diaphragm and valve plate/seals together to maintain

the performance of the pump.