Diaphragm pump N96_DC-B-M

Technical data

Translation of Original Operating and Installation Instruction, English, KNF 316836-316838 06/22

11

3 Technical data

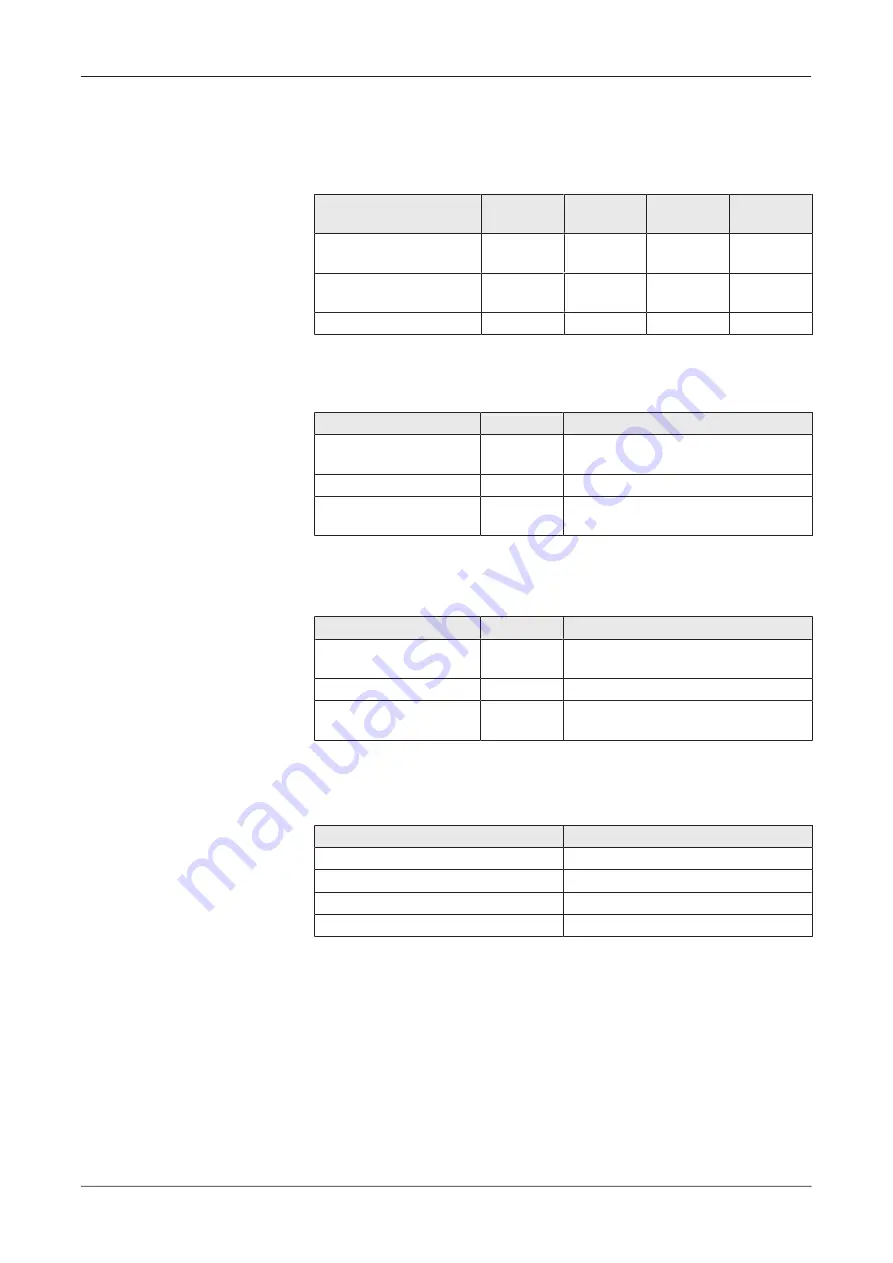

Technical data

Pump materials

Assembly

Material

KN

Material

KT

Material

AT

Material

ST

Pump head

PPS

PPS

Aluminum

Stainless

steel

Diaphragm

EPDM

PTFE-

coated

PTFE-

coated

PTFE-

coated

Valves

FKM

FKM

FKM

FFKM

Tab.5 Pump materials KN/KT/AT/ST variant

Pneumatic values

N96KNDC-B-M

Parameter

Unit

Value

Max. permissible oper-

ating pressure

[bar rel* /

psig]

2.5 / 36.4

Ultimate vacuum

[mbar abs.] <100

Flow rate at atm. pres-

sure

[l/min]**

8.5 ± 10%

Tab.6 Pneumatic values

*Bar rel related to 1013 hPa

**Liters in standard state (1013 hPa, 20°C)

N96_TDC-B-M

Parameter

Unit

Value

Max. permissible oper-

ating pressure

[bar rel*]

2.5

Ultimate vacuum

[mbar abs.] <130

Flow rate at atm. pres-

sure

[l/min]**

7.0 ± 10%

Tab.7 Pneumatic values

*Bar rel related to 1013 hPa

**Liters in standard state (1013 hPa, 20°C)

Pneumatic connections

Pump type

Value

N96K_DC-B-M

G 1/8

N96K_DC-B-M-NPT

NPT 1/8

N96ATDC-B-M

G 1/8

N96STDC-B-M

G 1/8

Tab.8 Pneumatic connections