Diaphragm liquid pump NF 25, NFB 25

Servicing

KNF Flodos AG BA_NF25_NFB25_EN_07_159615

Translated from the Original Operating and Installation Instructions

19

8. Servicing

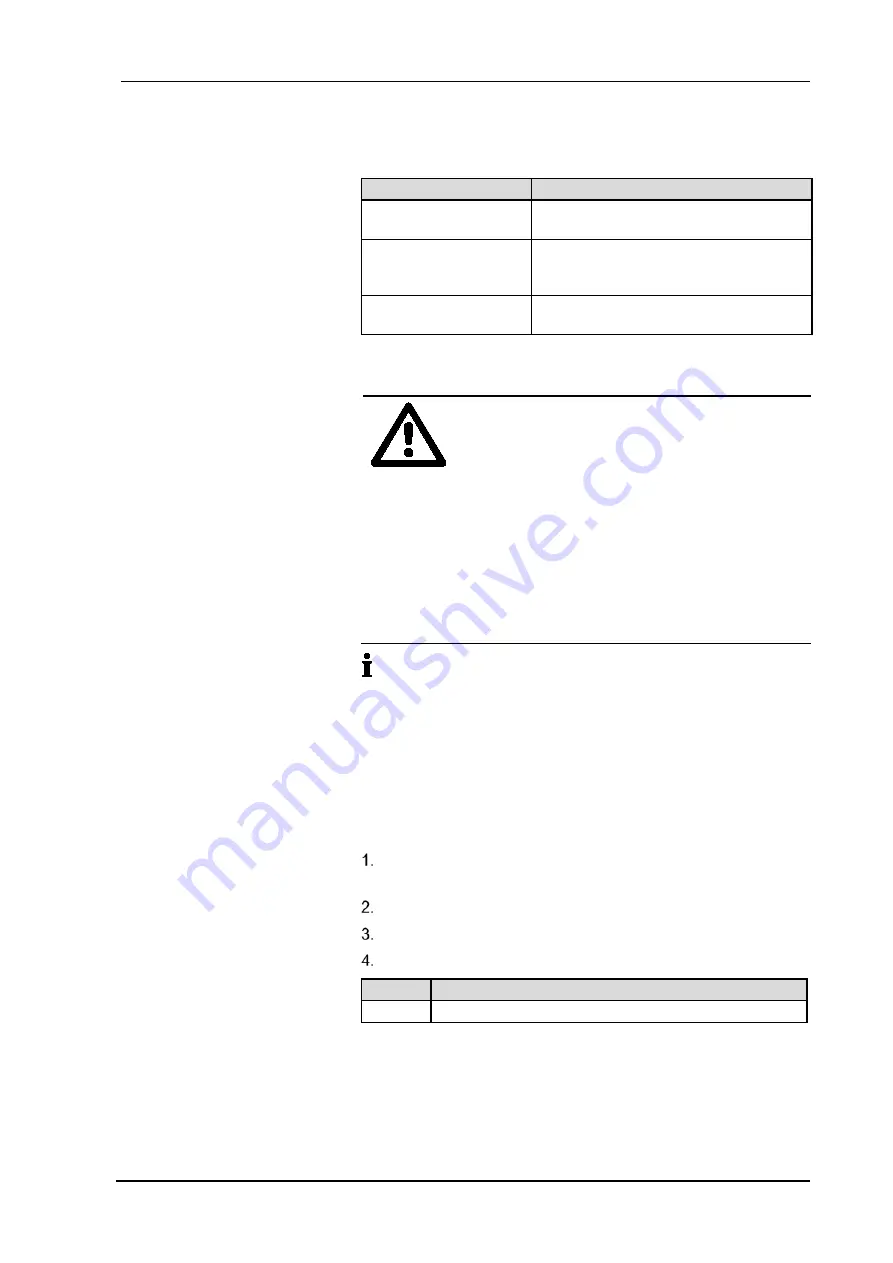

8.1. Servicing schedule

Component

Servicing interval

Pump

-

Regular inspection for external

damage or leaks

Pump head

-

Clean if the flow rate decreases, the

pump does not work or no vacuum

is created (Chapter 8.2)

Diaphragm, valve

plates and seals

-

Change as soon as pumping capac-

ity decreases, preferably sooner

Tab. 11

8.2. Cleaning and dismantling

WARNING

Health hazard due to dangerous

substances in the pump

Depending on the medium transferred, caustic burns

or poisoning are possible.

Wear protective clothing if necessary, e.g. pro-

tective gloves.

Flush the pump with a neutral liquid and pump

empty.

With NFB pumps, make sure that both pump

heads are flushed.

With NFB pumps the necessary steps are repeated for the

second pump head.

8.2.1. Flushing the pump

If transferring aggressive media, KNF recommends flushing

the pump with a neutral fluid under atmospheric conditions for

a few minutes before switching off, to extend the service life of

valves and diaphragm.

8.2.2. Preparations for disassembly

Flush the pump with a suitable neutralising liquid, and make

sure that no dangerous substances are left in the pump.

Pump empty.

Separate electrical connections.

Disconnect hoses from pump head.

Qty

Tools

1

T6 Torx screwdriver

Tab. 12

Information on procedure

Tools