KNF Micro BA317001-316999 NMP830_HP-EN 0221.docx

Translation of original Operating and Installation Instructions, English

Keep for future use

Operating and Installation Instructions

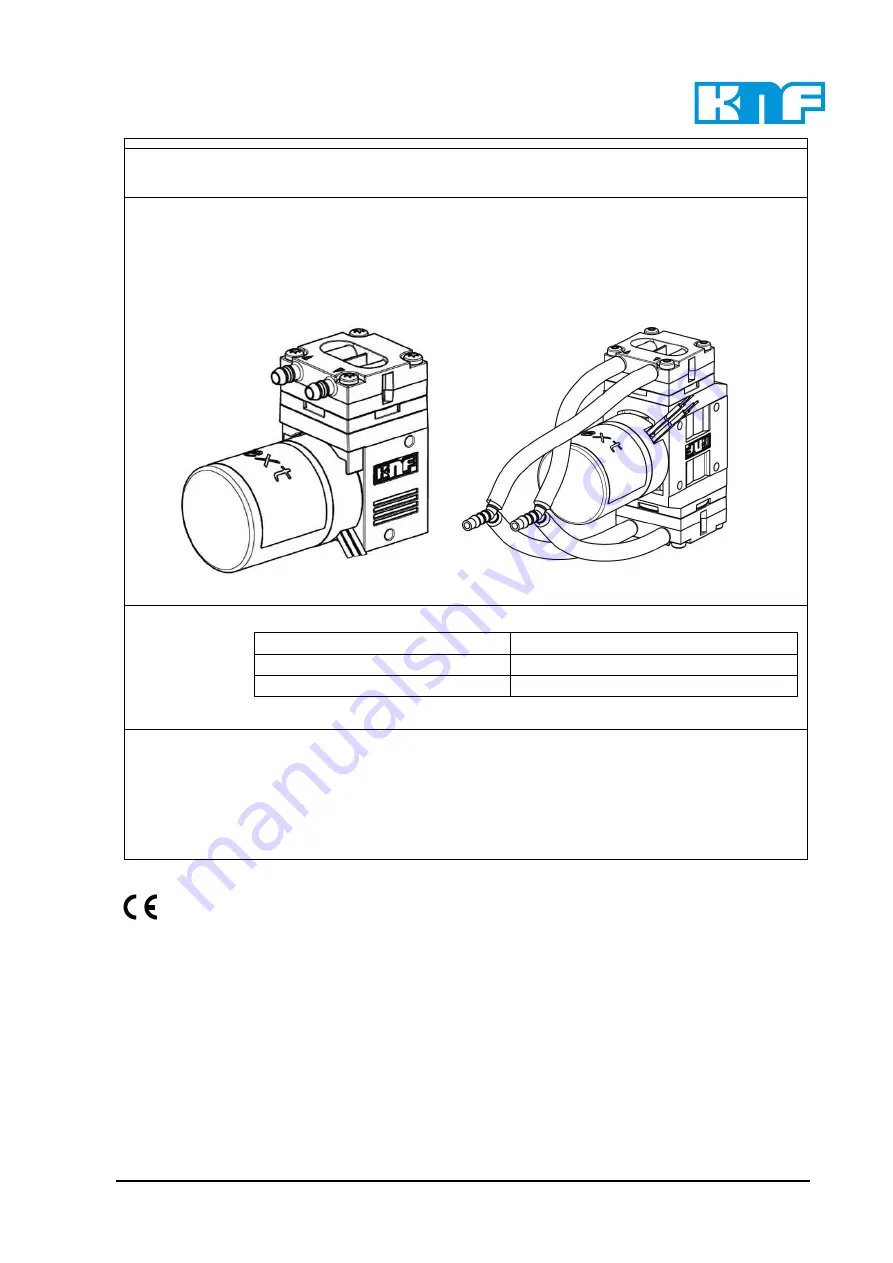

Micro Diaphragm Gas Sampling Pumps

Type range:

NMP830K_DC HP

NMP830K_DC-B HP

NMP830.1.2K_DC-B HP

NMP830K_DC-B4 HP

NMP830.1.2K_DC-B4 HP

You have selected a high-quality KNF product; the following tips will help you operate it safely, and

reliably over a long period of time. Carefully study the Operating and Installation Instructions before

using the pumps and observe at all times the relevant instructions to avoid dangerous situations. The

manual was produced for the serial pumps stated above. With customer-specified projects (pump

types starting with “PJM”, “PMM”, “PU” or “MPU“) there could be differences in detail. For customer-

specified projects please therefore take into account any agreed technical specifications, as well as

these instructions.

Contents

Page

About this document ................................................................. 2

Use ........................................................................................... 3

Safety ....................................................................................... 4

Technical data .......................................................................... 6

Assembly and function ........................................................... 10

Operation ................................................................................ 13

Servicing ................................................................................. 15

Troubleshooting ...................................................................... 16

Returns ................................................................................... 17

Product centre for

micro pumps

KNF Micro AG

Zelglimatte 1b

CH-6260 Reiden

Switzerland

Tel.

+41(0) 62 787 88 88

www.knf.com