Page 2 of 12

0901177 Rev: A (10/15)

CAUTION: Wear protective clothing and eyewear when dispensing chemicals or other materials.

Observe safety handling instructions (MSDS) of chemical mfrs.

CAUTION: To avoid severe or fatal shock, always disconnect main power when servicing the unit.

CAUTION: When installing any equipment, ensure that all national and local safety, electrical, and

plumbing codes are met.

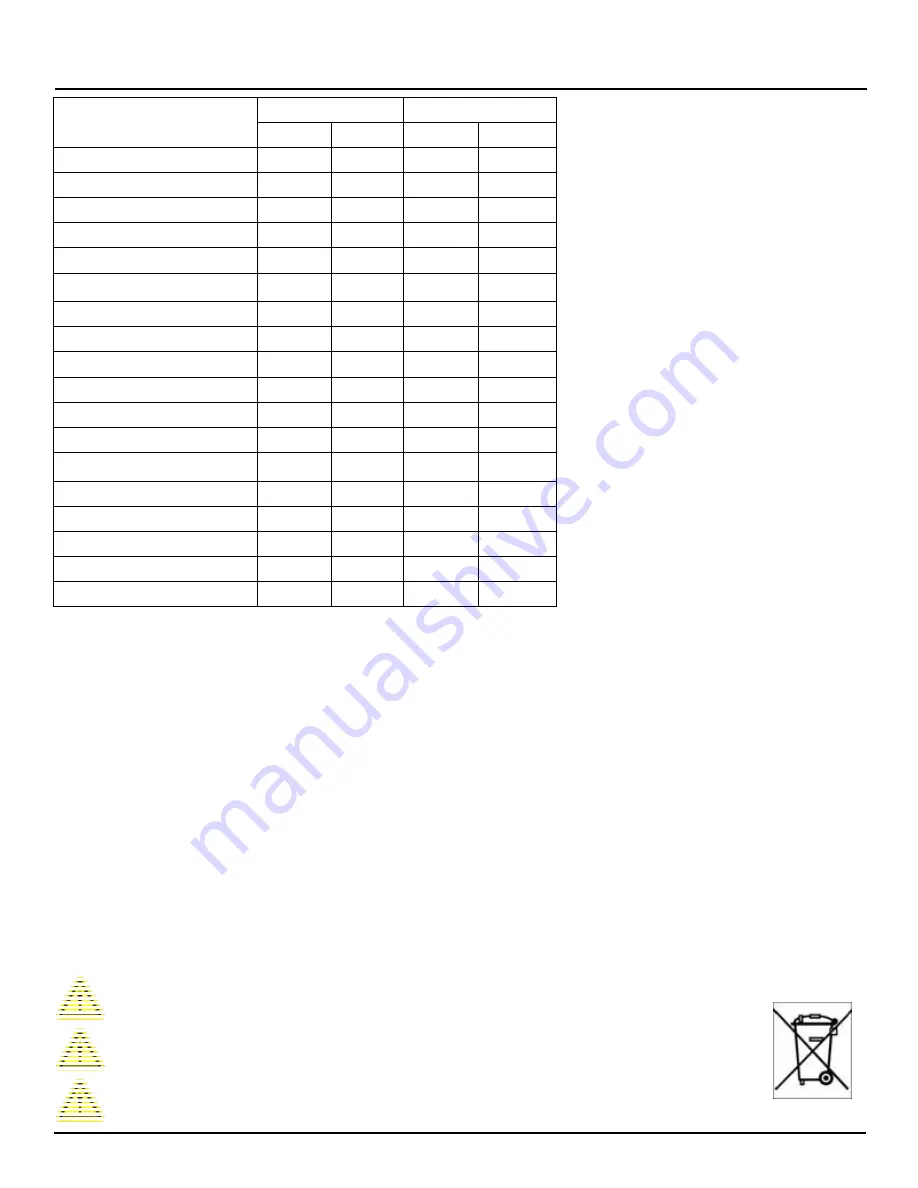

PROBE MODE

PROBELESS MODE

DOOR CONVEYOR DOOR CONVEYOR

RINSE SPEED

0 -100%

0 -100%

0 -100%

0 -100%

RINSE LIMIT

0 - 30s

NO

0 - 30s

NO

RINSE DELAY

0 - 14s

NO

0 - 14s

NO

INITIAL CHARGE

NO

NO

0 - 150s

0 - 128s

RECHARGE

NO

NO

0 - 30s

0 - 20s

RECHARGE AFTER N RACKS NO

NO

1 - 20

1 - 20

CONCENTRATION

0 - 199K

0 - 199K

NO

NO

ALARM DELAY

0 - 512s

0 - 512s

NO

NO

PASSWORD YES

YES

YES

YES

LANGUAGE YES

YES

YES

YES

RESET RACK COUNT

YES

YES

YES

YES

LOW LEVEL ALARM

YES

YES

YES

YES

CONCENTRATION ALARM

YES

YES

NO

NO

RACK TIME

NO

0 - 30s

NO

0 - 30s

INITIAL CHARGE REPEAT

NO

NO

YES

YES

WATER CHANGE COUNT

0 - 999

0 - 999

0 - 999

0 - 999

DETERGENT PULSE %

10 - 90%

10 - 90%

NO

NO

DETERGENT PULSE RATE

3 - 15s

3 - 15s

NO

NO

SETTINGS GUIDE

Default Settings

System is in Conductive Probe Mode

System is set for Door Machines

Detergent Pulse Rate is 5 Seconds (dry) or 3

Seconds (liquid)

Default Password is 0000

Rinse Pump Speed is 50%

Detergent Concentration Setpoint is 25

Detergent Alarm Delay is set to 64 Seconds

Rinse Limit is 30 Seconds

Detergent Percentage Pulse is 50% (dry) or

85% (liquid)

Rinse Delay is 0 Seconds

Initial Charge is 30 Seconds

Initial Charge Repeat is On

Recharge is 5 Seconds

Change Water Count is 0 Racks

Number of Racks between Recharge is 1

Rack Time is 12 Seconds

Equipment Ratings

This includes equipment supply, description of I/O

connections, duty cycle and operating environmental

conditions.

Pollution degree 2

Installation category 2

Altitude <2187 yard (<2000 m)

Humidity 50% to 80%

Electrical supply 120, 208, or 240 Vac, 50/60 Hz

Mains supply voltage fluctuations are not to exceed 10

percent of the nominal supply voltage

Indoor use only

Temperature 41°F to 104°F (5°C to 40°C)

Rinse flow rate: .135 oz/min—1.96 oz/min (4-58 ml)

Detergent flow rate: 16.9 oz/min (500ml/min)