1

Knorr-Bremse Group

PD-203-500

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring.

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

DATA

P r o d u c t

C o m m e r c i a l V e h i c l e S y s t e m s

KB4TA D System Overview

Doc. No. Y250905 (EN - Rev. 000)

July 2016

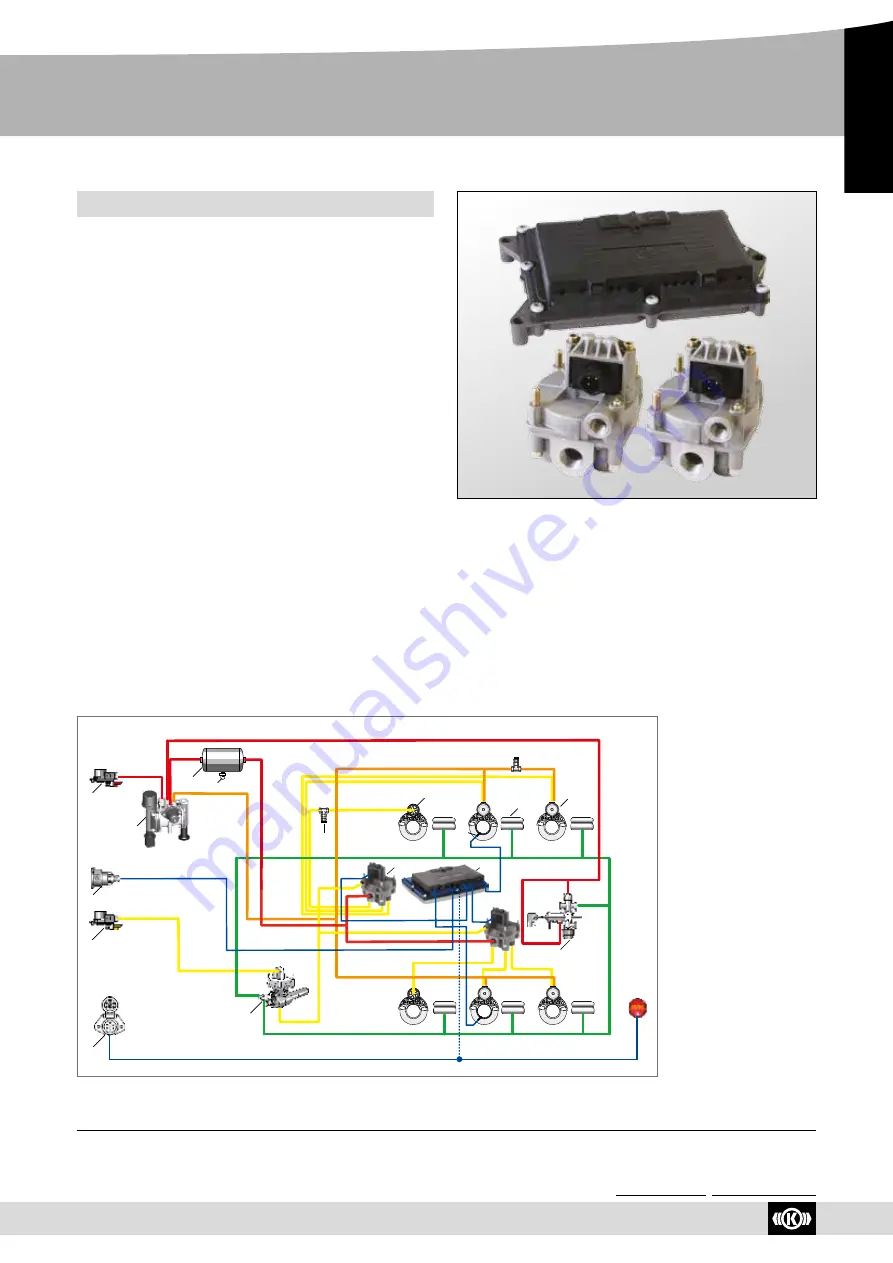

The Basic Knorr-Bremse

KB4TA D

brake system

comprises a KB4TA D ECU ES1220

(see PD-203-530,

Document No.

Y250907

) plus two ABS Modulator

Valves (see PD-203-360, Document No.

Y250908

) and

is designed for air braked trailers with mechanical or air

suspension.

KB4TA D

is designed to work in trailer systems powered

via ISO 7638 but the addition of ISO 1185 stop lamp

powering is included as standard as a safety feature so,

in the event that there is no ISO 7638 powering, the ABS

function is maintained.

Note: Stop lamp powering should only be considered

as a backup in the event of failure of the ISO 7638

connection.

The

KB4TA D

ECU is designed for all normal

system variants from 2S/2M up to 4S/3M. The configuration as supplied is 2S/2M, but with the integrated

auto-configuration the ECU detects additional sensors and adjusts upward to 4S/2M automatically.

Other configurations and additional functions can be quickly and effectively achieved using PC Software

ECU

talk

®

. For 4S/3M applications an additional external (third) ABS modulator is necessary (see

PD 203-360, Document No.

Y250908

).

The

KB4TA D

brake system is capable of working with drum brake or disc brakes and the systems shown below are

only typical. For more systems see PD-203-580, Document No.

Y250913

.

Function

KB4TA D System diagram (2S/2M) for semi-trailer with air suspension and disc brakes

(ECU mounted above centre of bogie)

Legend:

1 Coupling Head with Filter -

“Supply”

2 Coupling Head with Filter -

“Control”

3 ABS Connector ISO 7638

4 Park / Shunt Valve with

Emergency Function and

integral Charging Valve

5 Air Reservoir

6 Drain Valve

7 Load Sensing Valve

8a ABS ECU

8b ABS Relay Modulator Valve

9 Brake Chamber

10 Spring Brake

11 Sensing Ring and Wheel Speed

Sensor

12 Air Spring Bellow

13 Levelling Valve

14 Test Connector

15 Electrical Connector “Lighting”

acc. to ISO 1185

kb4tad_sys_001

1

2

3

7

5

6

4

8a

14

9

12

10

13

8b

11

15

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: