7

Knorr-Bremse Group

PD-203-430

ES1305

Doc. No. Y250906 (EN - Rev. 000)

July 2016

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring.

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

KB4TA ABS Module

C o m m e r c i a l V e h i c l e S y s t e m s

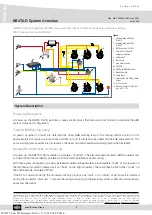

1) Fit the KB4TA module to the trailer, normally on a cross member in the centre of the rear axle bogie.

2) If required fit the additional axle modulator, normally on a cross member in the centre of the front axle bogie.

3) Make the necessary pneumatic connections.

4) Make the necessary electrical connections - see PD-203-380, Document No.

Y250909.

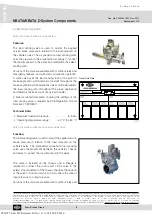

Required checks after installation

1) Before performing the checks, chock the wheels.

2) Fully charge air brake system and verify proper brake adjustment.

3) Make several trailer brake applications and check for prompt application and release at each wheel brake.

4) Check the module, modulator valve(s) and all air hose fittings for leakage using a soap solution.

5) Apply power and monitor the power-up sequence to verify proper system operation.

6) Determine the current ABS configuration by activating blink code diagnostics or using the PC diagnostic tool

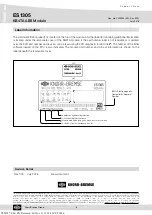

ECU

talk

®

(see PD-203-390, Document No.

Y250910

).

7) Where necessary configure the required ABS configuration and Auxiliary configuration using the diagnostic tool

ECU

talk

®

.

8) It is recommended that a full EOL check is carried out using the diagnostic tool ECU

talk

®

.

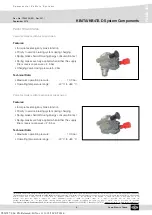

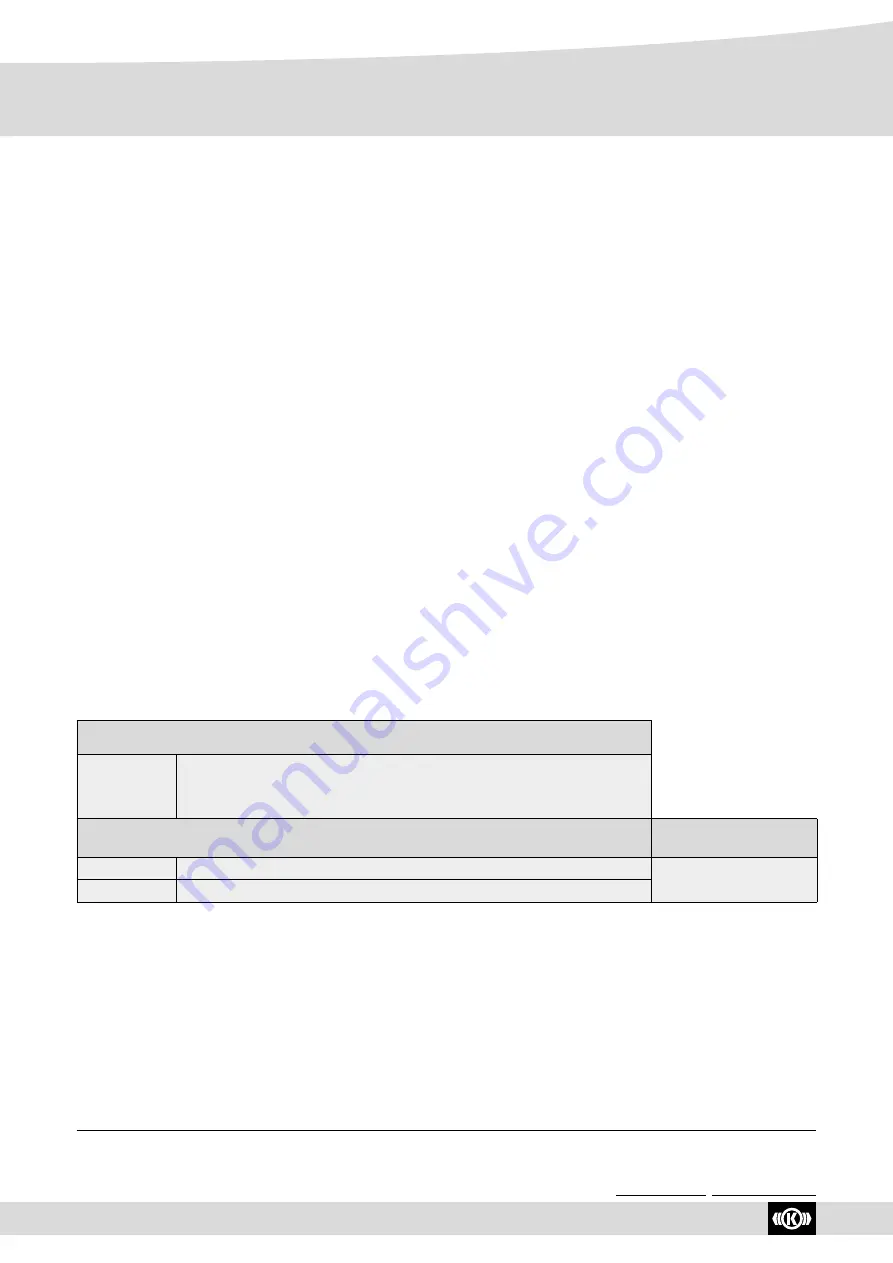

Pipe sizes

The following table defines the minimum bore of piping to be used to connect the reservoir to the module and the

module to the respective brake actuators.

Pipe size for the connection between the air reservoir and the module

Plastic pipe

Minimum inside diameter 12 mm

It is recommended that both Supply ports are used and each is

connected to the reservoir.

Pipe size for the connection between the module and the service brake actuators

Maximum length

Plastic pipe

Minimum inside diameter 9 mm

5 m

Rubber hose

Minimum inside diameter 11 mm

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: