10

Knorr-Bremse Group

PD-203-360

Doc. No. Y250908 (EN - Rev. 001)

September 2016

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring.

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

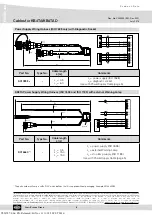

KB4TA/KB4TA D System Components

P r o d u c t D a t a

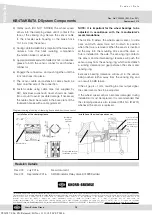

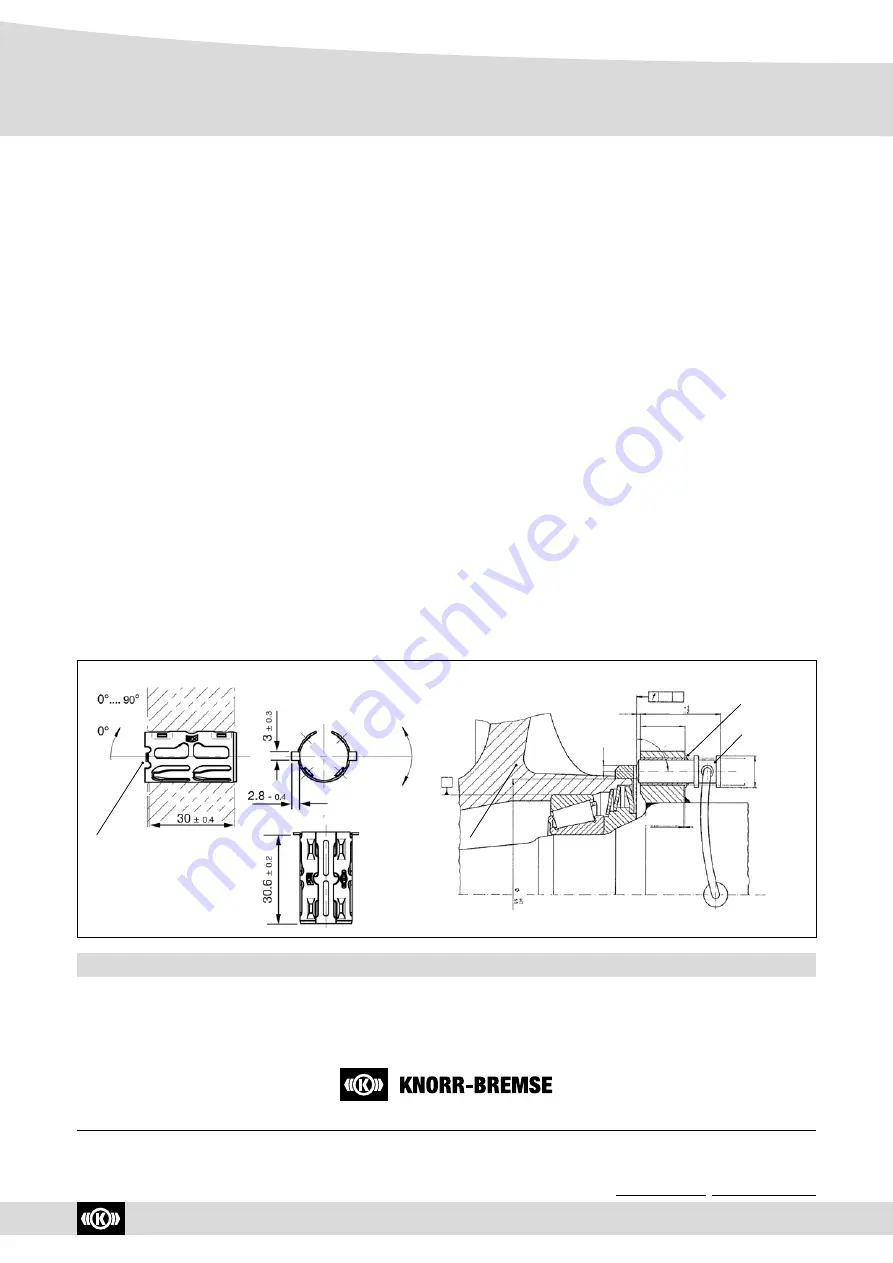

Diagram showing mounting of clamping sleeve and wheel speed sensor

Installation of the clamping sleeve

Pressed in fully

Permissible vertical

installation position

Installation

position

optional

Installation of the wheel speed sensor

3

+2

54

0.2 A

>3.5

0.6

±0.2

x45°

A

Ø18

H11

Ø21

30

±0.4

90

± 2.5

Sleeve pressed in

against the stop

Sensor carefully

inserted (do not

use a hammer!)

Rev. 000

July 2016

New document.

Rev. 001

September 2016

ABS Modulator Relay Valve K019299 added.

3) Gently push (DO NOT STRIKE) the wheel speed

sensor into the clamping sleeve until it contacts the

face of the sensing ring. Secure the sensor cable

to the knuckle/ axle housing or the brake hose

10-15 cm from the sensor.

4) During cable installation it is important that maximum

distance from the heat radiating components

(foundation brake) is achieved.

5) Apply a moderate amount of dielectric non-conductive

grease to both the sensor connector and harness

connector.

6) Engage the connectors, and push together until the

lock tab snaps into place.

7) The sensor cable and extension cable should be

fixed on either side of the connection.

8) Fasten cables using cable clips (not supplied by

KB), individual suspension travel should be taken

into account to avoid possible damage. If necessary

the cable should be secured in the back plate of the

foundation brake with a cable grommet!

NOTE: It is important for the wheel bearings to be

adjusted in accordance with the manufacturer’s

recommendations.

The friction fit allows the wheel speed sensor to slide

back and forth under force but to retain its position

when the force is removed. When the sensor is inserted

all the way into the mounting block and the drum or

hub is installed on the axle, the sensing ring contacts

the sensor and normal bearing clearance will push the

sensor away from the sensing ring, which will establish

a running clearance (air gap) between the sensor and

sensing ring.

Excessive bearing clearance will result in the sensor

being pushed further away from the sensing ring and

can result in ABS failure.

If the air gap is >1 mm, resulting in a low output signal,

the speed sensor has to be adjusted.

If the wheel speed sensor becomes damaged during

installation it must be replaced. It is recommended that

the clamping sleeve is also replaced (Part No.

II

16774)

whenever the sensor is replaced.

Revision Details

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: