Knorr-Bremse Group

5

Doc. No. Y250910 (EN - Rev. 001)

September 2016

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

KB4TA / KB4TA D System Diagnostics

C o m m e r c i a l V e h i c l e S y s t e m s

PD-203-390

Diagnostic Trouble Codes — Blink Code Quick Reference

1st Blink Code

2nd Blink Code

Information on action required

Code

Location

Code

Description

1

All

1

No Faults

System fully operational - no faults detected

2

3

4

5

Sensor SL

Sensor SR

Sensor SAL

Sensor SAR

1

Wheel speed sensor air gap is too big

Go to Chart 5

2

Loss of wheel speed sensor signal

Go to Chart 5

3

Noisy wheel speed sensor signal

Go to Chart 5

4

Short or open circuit wheel speed sensor

Go to Chart 5

5

Tyre size differential out of range

Verify correct tyre size, proper tyre inflation & correct number

of sensing ring teeth. Verify that the ECU has the correct tyre

size settings.

6

Wheel speed sensor configuration error

Verify correct ABS configuration.

6

Power Supply

1

Voltage too high

Go to Chart 4

2

Voltage too low

Go to Chart 4

3

Excessive resistance ISO 7638 pin 1

Go to Chart 4

7

8

9

Modulator M22

Modulator M21

AUXIO1 / Modulator

2

Exhaust solenoid shorted or open circuit

Go to Chart 6

3

ABS valve installation error

Go to Chart 6

4

Valve configuration error

Verify correct ABS configuration.

10

Common

1

Internal short to ground

Check for damaged or corroded connectors. Check for

damaged wiring. After corrections or if no issues found, then

clear trouble codes. If problems return, replace the module.

2

AUXIO1 or modulator 2 short to ground

Go to Chart 6

3

ABS modulator dynamic error - all valves

Go to Chart 6

4

Excessive ABS activity

Go to Chart 4 or Chart 6

5

AUXIO1 or modulator 2 short to battery

Go to Chart 6

11

ECU

1

Internal error

Check for damaged or corroded connectors. Check for

damaged wiring. After corrections or if no issues found, then

clear trouble codes. If problems return, replace the module.

2

Configuration error

Verify correct ABS configuration.

12

AUXIO2

1

Shorted or open circuit

Check for corroded/damaged wiring or connectors

13

AUXIO3

1

Shorted or open circuit

Check for corroded/damaged wiring or connectors

14

System

2

Service Interval Exceeded

...

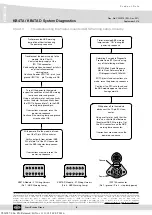

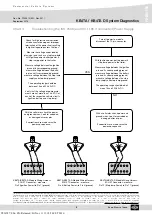

To Read Diagnostic Trouble Codes (DTCs):

1) Apply constant power to the trailer (towing vehicle ignition switch).

2) Within 15 seconds, apply/release the brake pedal at 1 second intervals:

(a) 3 times for displaying “Active” DTCs.

(b) 4 times for displaying “Inactive” DTCs.

3) Observe the dashboard mounted ABS warning lamp and record blink code(s).

4) Refer to blink code chart for description.

5) After resolving problems, verify that the warning lamp is no longer illuminated.

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: