10

Knorr-Bremse Group

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring..

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

Doc. No. Y250910 (EN - Rev. 001)

September 2016

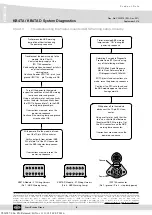

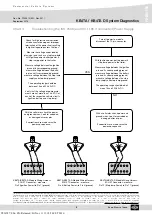

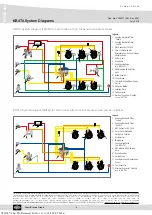

KB4TA / KB4TA D System Diagnostics

P r o d u c t D a t a

PD-203-390

Chart 5

Troubleshooting the Wheel Speed Sensors

* Note: Both static and dynamic wheel speed

sensor DTCs may be present.

X1

X2

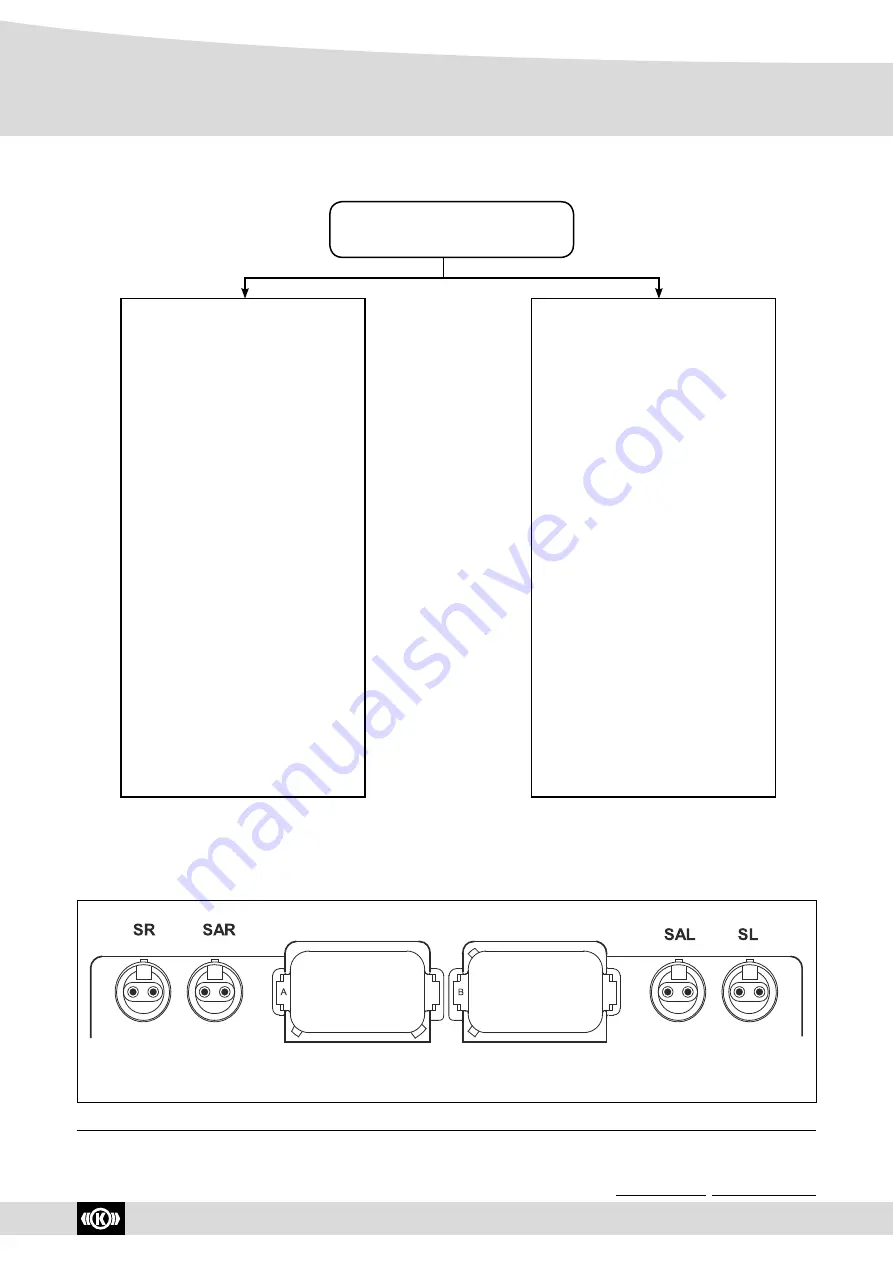

KB4TA and KB4TA D Modules - WSS Pinning

SR -

Right Sensor

SAR- Additional Right Sensor

SL -

Left Sensor

SAL- Additional Left Sensor

Turn off power to module.

If Dynamic WSS DTC(s) is present: *

Rotate the effected wheel and verify

a minimum of 0.25 Volts AC

sensor output at 0,5 rev/sec across the

wheel speed sensor pins. A correctly

adjusted sensor can output more than

2.0 Volts AC at 1 rev/sec.

Verify/Inspect the following:

–

Is the speed sensor pushed in

completely?

–

Condition and retention force of sensor

clips.

–

Correct sensor lead routing and

clamping.

–

Condition of sensing ring mounting

and teeth.

–

Correct number of sensing ring teeth

per sensed wheel.

–

Correct adjustment of wheel bearings.

–

Condition of foundation brakes.

Make corrections as needed (replace

wiring and/or ABS components). Re-

connect all connectors to the module.

Then rerun the power-up sequence.

If static WSS DTC(s) is present: *

Using a volt/ohm meter to measure the

connector pins of the problem sensor,

verify 950-1950 Ohms across sensor

connector pins.

Verify/Inspect the following:

–

No continuity from sensor connector pins

to ground.

–

Vbat not measured at either sensor

connector pins.

–

Sensor/ECU wiring and connectors are

not damaged or corroded.

–

Correct sensor lead routing and

clamping.

If an issue with the wiring is found isolate

the area needing correction by repeating

the measurements at all connections.

Make corrections as needed (replace

wiring and/or ABS components). Recon-

nect all connectors to the module.

Then check for dynamic wheel speed

sensor DTCs, see left column.

Then rerun the power-up sequence.

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: