TEMON 4-C

Doc. N°

MO-0368-ING

Microener. - Copyright 2010

2.1

Date

01.12.2008

Rev.

0

Pag.

11

of

14

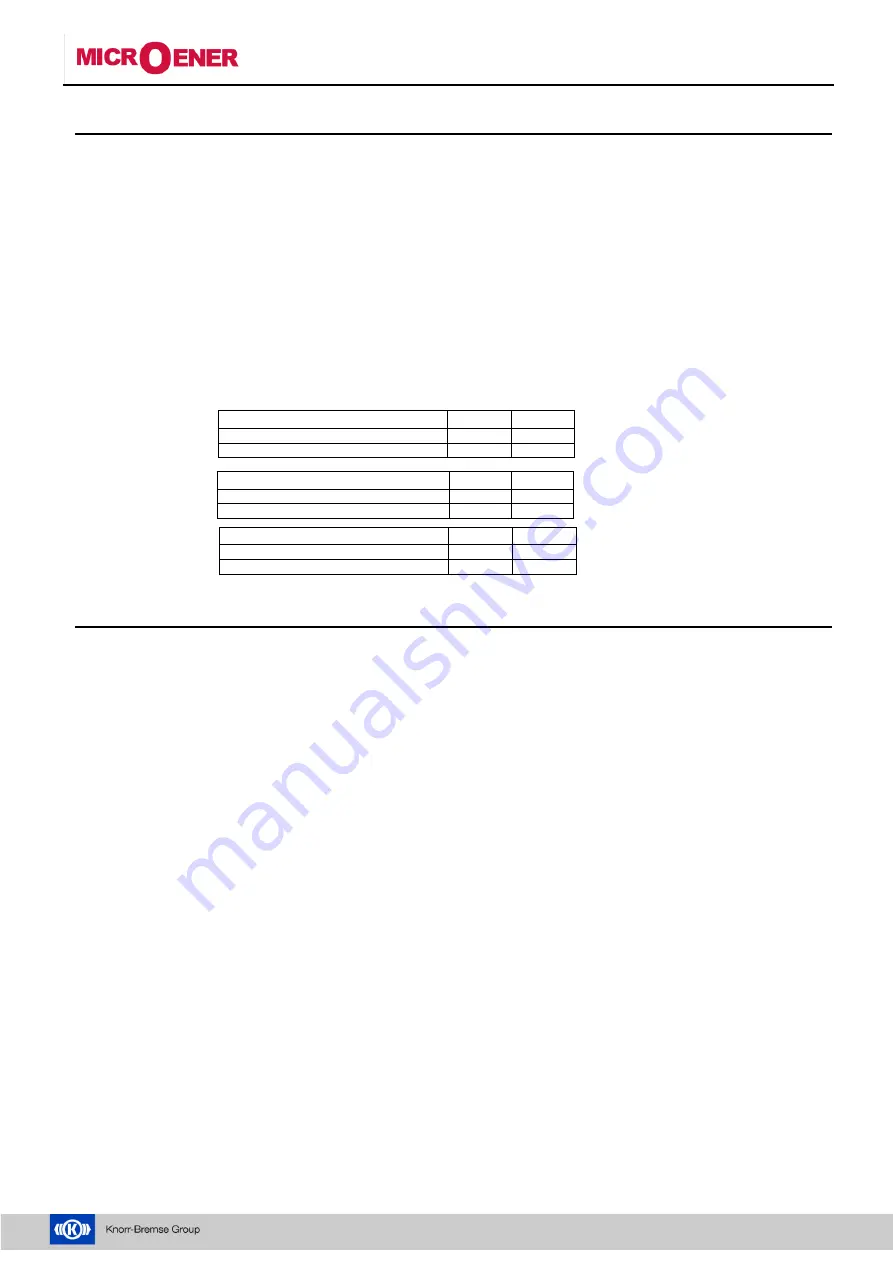

9.13 - Configuration diagnostic probes

This function allows to enable or to disable the control on the probes.

The function control the variation of the temperature in a defined time. There is a problem if this variation is higher

than a set value.

It’s necessary to set the maximum variation temperature:

FDC: min 5 °C

– max 30 °C

and after the time in which to do the control:

FDC: min 10” – max 90” (period in seconds)

The

+

key is used to increase the values while the

-

key to decrease.

Confirm with ENTER.

9.14 - The exit of the programming phase

Press the SET key or wait for about 8 seconds without to press any key to come out of the programming phase.

Setting FDC modality

T1-T2 T3-T4

FDC mode disabled

FDC

Off

FDC mode enabled

FDC

ON

Temperature

configuration

FDC

T1-T2

T3-T4

Min °C

FDC

-5°

Max ° C

FDC

30°

Period configuration FDC

T1-T2

T3-T4

Min in seconds

FDC

10’’

Max in seconds

FDC

90’’