15

3

Service Instructions

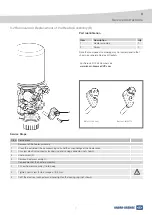

Fig. 2

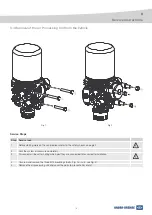

Fig. 3

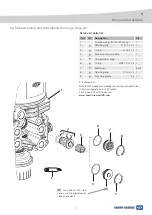

Fig. 4

Fitting the oil separator

Step

Service task

1

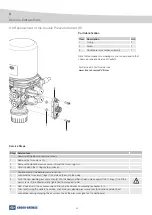

Check that the sealing surfaces of the oil separator unit (1) and the cartridge neck (not shown) are clean. Fit the

new O-rings (2 and 3) (Fig. 1 on Page 15) and lightly grease them.

2

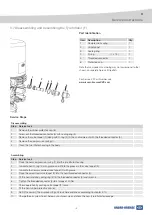

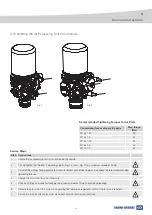

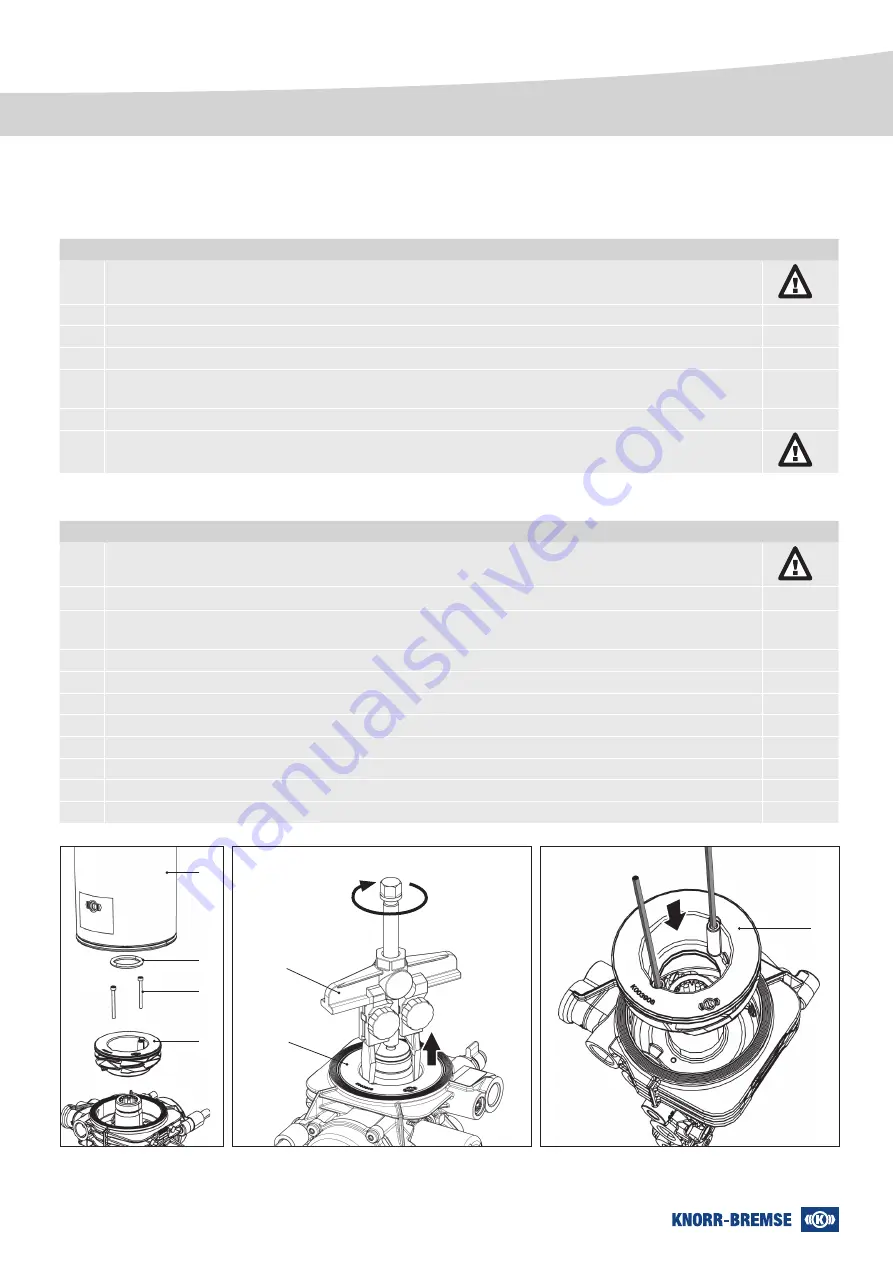

Put 2 rods (Ø 2.5 mm) (Fig. 4) into the threads for screws (4) to guide the oil separator into the body (Fig. 4).

3

Place the new oil separator unit (1) or cleaned original unit (dependent on kit purchased) into the body. Push the

unit down until it is correctly seated.

4

Fit and tighten screws (4) to a torque of 2.5 Nm.

5

Lightly lubricate the gasket at the base of the cartridge (6) with grease.

6

Lubricate new O-ring (5) with grease.

7

Fit O-ring (5) over the cartridge retaining thread.

8

Screw desiccant cartridge (6) up to stop.

9

Fully tighten desiccant cartridge (6) by turning a further ½ turn using a suitable strap wrench.

10

Refit (if necessary) the air processing unit to vehicle and check according to chapter 3.10.

11

Charge the air system to just below cut-out pressure and check the desiccant cartridge for leakage.

Removing the oil separator

Step

Service task

1

Clean the outside of the air processing unit and its surroundings to prevent entry of dirt.

2

Secure the ZB44.. either to a simple fixture or using the mounting bolts/studs to make it stable.

3

Unscrew desiccant cartridge (6) counter-clockwise, using suitable strap wrench.

4

Remove the screws (4) and O-ring (5).

5

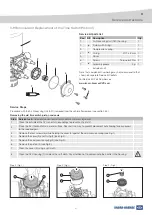

Fit a suitable pulling tool (7) into oil separator unit (Fig. 3). For detailed specification and correct fitting of

recommended tool see page 16.

6

Pull out the oil separator unit (1) by using of pulling tool (7).

7

If the oil separator unit (1) is not being replaced (depending on kit purchased), clean the the original unit (1) with

water using a high pressure hose or alternatively with gasoline. Also clean the housing using a soft cloth.

Service Steps

1

4

5

6

1

1

7