5

Introduction

1

1 1 Service Intervals

The service interval is the length of time from the vehicle

first entering service, or from the last service, until the point

in time – or distance travelled by the vehicle (whichever is

the earlier) – when it is recommended that the specified

braking system device is serviced using a genuine

Knorr-Bremse service kit or replaced with a new part, or in

the case of ABS subjected to a system functionality check.

This service interval is provided for preventative

maintenance purposes so as to minimize the probability of a

vehicle breakdown.

The service interval does not preclude the intermediate

testing of the device on the vehicle to ensure that it is

functioning in a correct manner, or the correct maintenance

of other devices in the system that may influence the

service interval.

The service interval can be influenced by the application

and the operating conditions of the vehicle. The following

service intervals are based on the assumption that each

device is positioned so it cannot be inadvertently abused

or that external rubber boots/seals are not exposed to

abnormal influences.

In general, Knorr-Bremse service kits contain all of the

components that can deteriorate with use, such as rubber

parts (O-rings, special seals, bonded inlet/exhaust valves,

exhaust flaps), plastic and metal parts (filter elements and

springs), fasteners and the correct grease. The range of

kits is designed to enable each device to be serviced in

part or completely.

Knorr-Bremse service kits are only designed for use with

genuine Knorr-Bremse devices and are only to be used

in the manner detailed in these service instructions.

After servicing, the device must also be checked in

accordance with Knorr-Bremse service instructions to

ensure correct operation before the vehicle is placed back

in service.

Additional checks

In addition to the above, and any legally required periodic

vehicle inspections, it is recommended that simple routine

inspections of a general nature are carried out to maintain

the braking system at a high level of functionality. These

simple routine inspections should be (1) the weekly checking

for excess water in the reservoirs by operation of the

reservoir drain valves, and (2) the 6 monthly / (50,000 km)

checking of the complete braking system for excessive air

leakage during a maximum pressure foot brake application

with the vehicle stationary and the parking brake released.

Service interval

Service

Notes

Refer to vehicle manufacturer.

30 000 km recommended.

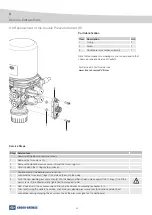

Clean the oil separator and replace the O-Rings

(If necessary the service interval can be revised,

depending on the amount of oil carryover).

Failure of the air processing unit to purge

or non-replacement of the desiccant

cartridge at the recommended interval

can cause a reduction in the service

interval of downstream components.

Refer to vehicle manufacturer.

1 year recommended.

Replace the desiccant cartridge.

Replace the oil separator, if necessary.