6

Introduction

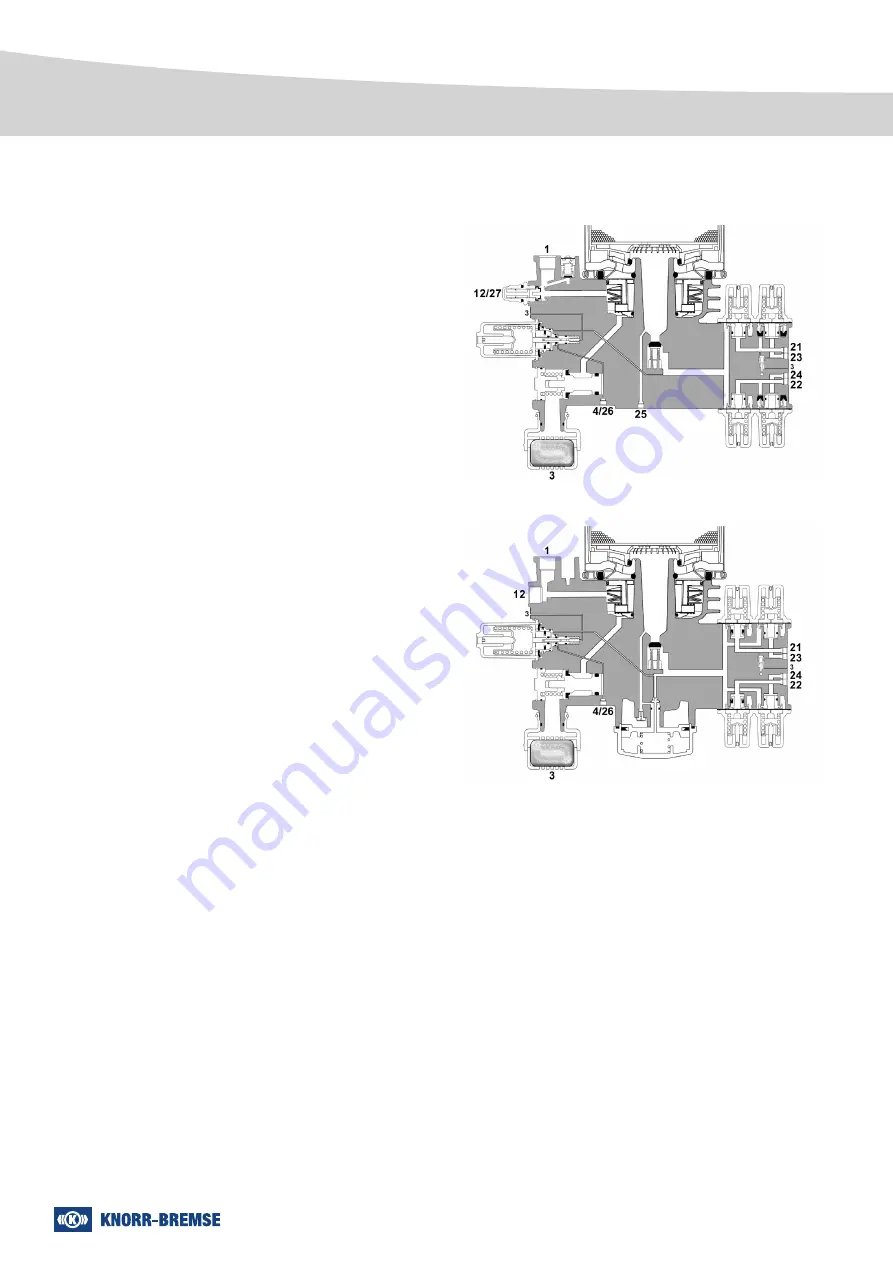

1

1 2

Basic principles

The ZB44.. range of air processing units combines

the functions of a conventional air dryer with those of a

pressure regulator and multi-circuit protection valve in one

monoblock

housing.

1 2 1 Features

• Classic air drying functionality

• Multi-circuit protection valve functionality

• Integrated unloader function

• Integral safety function (air dryer)

• Exhaust safety function (Multi-circuit protection valve,

EC

)

• Two integrated pressure sensors (Optional)

• ESS Compressor control (Optional but recommended)

• Regeneration either via reservoir or by time switch

• High pressure tyre inflation with safety valve (Optional)

• System pressure tyre inflation (Optional)

• Air suspension supply (Optional)

• Heater (Optional)

• Oil separator (Optional)

• Silencer type (Optional)

1 2 2 Functionality

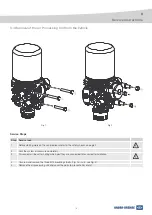

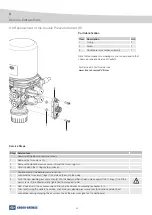

The air processing unit is fitted in the compressor discharge

line of an air braking system to remove water, dirt, carbon

and oil from the compressed air and therefore prevent it

entering the vehicle air reservoirs during the

Charge

phase.

It controls the system pressure (unloader function). It also

maintains a pre-set pressure in the unaffected circuits of a

multi circuit braking system in the event of a failure in one

circuit (multi-circuit protection valve function).

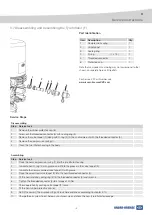

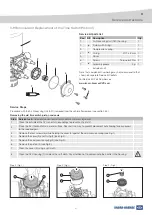

When the increasing air pressure in the braking system

reaches a preset value (cut-out pressure), the unloader

valve signals the purge valve to open and the air processing

unit enters the

Purge

phase. This allows the trapped dirt

and condensate to be expelled and the desiccant to be

regenerated with clean, dry air from a separate purge

reservoir or with air from the brake system using an integral

timer. During this phase, air delivered by the compressor is

discharged to atmosphere and does not enter the braking

system. When, due to normal usage, the air pressure in

the braking system drops, to the closing pressure of the

unloader valve, it signals the purge valve to close and the

Charge

phase begins again.

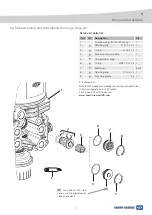

1 2 3

Air dryer element

Drying function

During the

Charge

phase, compressed air enters the air

processing unit through port

1

and passes through the

oil separator element to remove particles and oil from the

air using the cyclotron principle. This helps to maintain

the quality of the desiccant bed, prolonging its life and

effectiveness. It continues up the outside of the inner

desiccant cartridge and then passes down through the

desiccant bed to remove the water vapour. The now clean,

dry air opens the delivery check valve, flows through the

multi-circuit protection valve, and is delivered from ports

21

,

22

,

23

and

24

to charge the vehicle braking system.