ADjUSTMENTS

10

Depth of Cut

The cutting depth scale (Figure 31) is a combination

inch/metric scale, with a cutting range from 0 to 6” (152.4mm).

The distance of upward or downward movement is controlled

by the handwheel. Before moving the table up or down, loosen

the locking handles (Figure 31). After obtaining proper table

position, tighten the locking handles.

Maximum depth of cut is 3/16”. A limiter on the front of the

head casting limits the depth of cut on full width planing under

1/8”.

Periodic inspections are required to ensure that the machine

is in proper adjustment, that all screws are tight, that belts

are in good condition and properly tensioned, that dust has

not accumulated in the electrical enclosures, and that there

are no worn or loose electrical connections.

Buildup of sawdust and other debris can cause your machine

to plane inaccurately. Periodic cleaning is not only

recommended but mandatory for accurate operation.

Close-fitting parts, such as the cutterhead slots and gibs,

should be cleaned with a cloth or brush and non-flammable

solvent, and freed from clinging foreign matter.

Remove resin and other accumulations from feed rollers and

table with a soft rag and nonflammable solvent.

Periodically check all the chains for proper tension and adjust

accordingly if needed.

The table should be kept clean and free of rust. Some users

prefer a paste wax on exposed steel and cast iron surfaces.

The wax provides a layer of protection as well as reducing

friction between lumber and the table, making cuts faster and

smoother. Avoid any wax that contains silicone or other

synthetic ingredients. These materials can find their way into

lumber and can make staining and finishing difficult.

Another option is talcum powder applied with a blackboard

eraser rubbed in vigorously once a week; this will fill casting

pores and form a moisture barrier. This method provides a

table top that is slick and allows rust rings to be easily wiped

from the surface. Important also is the fact that talcum

powder will not stain wood or mar finishes as wax pickup does.

Figure 31

Limiter

Locking

handle

Scale

MAINTENANCE

Before doing maintenance on the machine,

disconnect it from the electrical supply by

pulling out the plug or switching off the main

switch! Failure to comply may cause serious

injury.

WARNING

Lubrication

All ball bearings are factory lubricated and sealed for life.

They require no further lubrication.

The lubricant in the gear box must be drained and replaced

every 2,500 hours. Multi-purpose gear box lubricant will be

suitable.

To replace the lubricant:

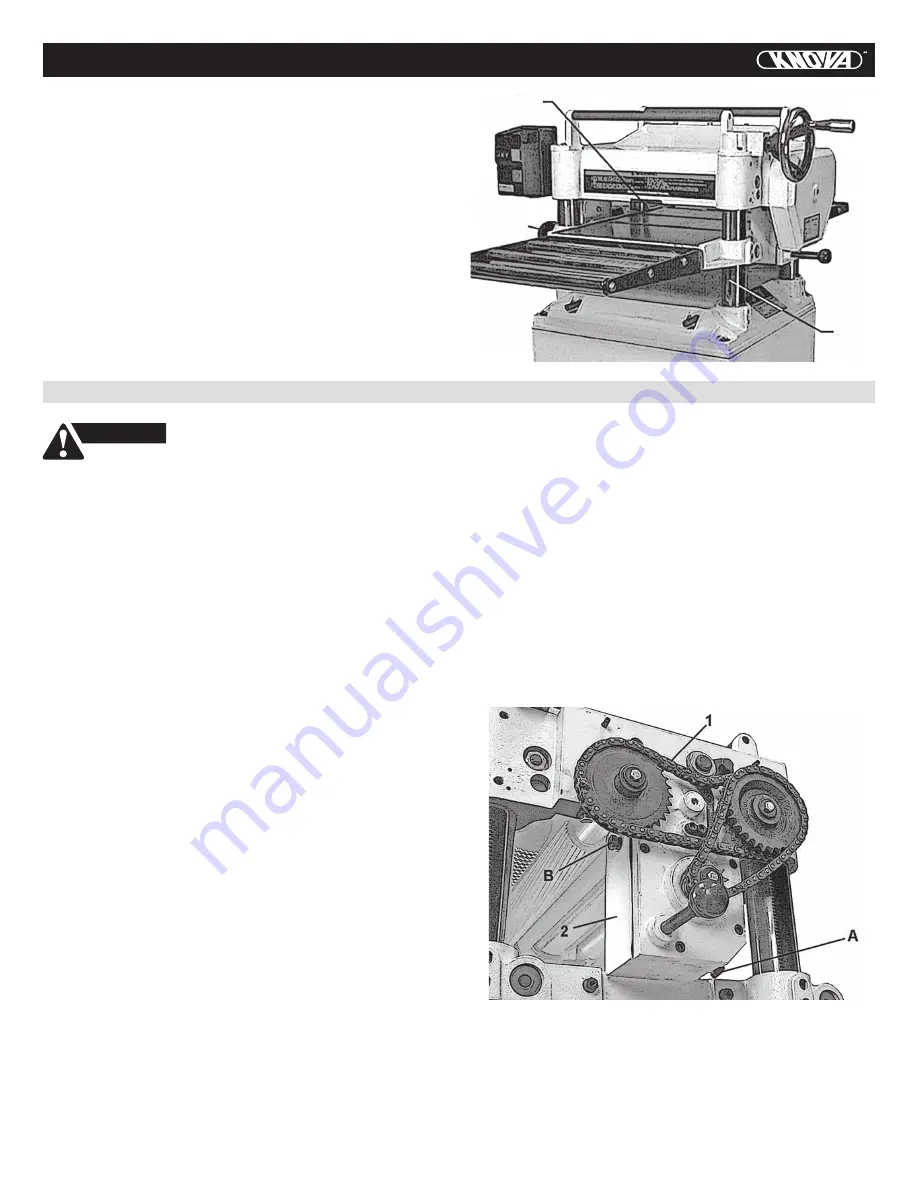

1. Remove the drain plug (A, Figure 32) with a 14mm wrench.

Drain dirty oil thoroughly.

2. Insert and tighten the drain plug. (A, Figure 32).

3. Remove filler cap (B, Figure 32) and fill with clean lubricant

through the hole. Fill until the oil reaches the top of the filler

plug port for correct oil level.

4. Install and tighten filler cap (B, Figure 32).

Figure 32

Summary of Contents for KN CM-15W3

Page 43: ...42 NOTES NOTAS ...

Page 44: ...www knova com mx ...