12

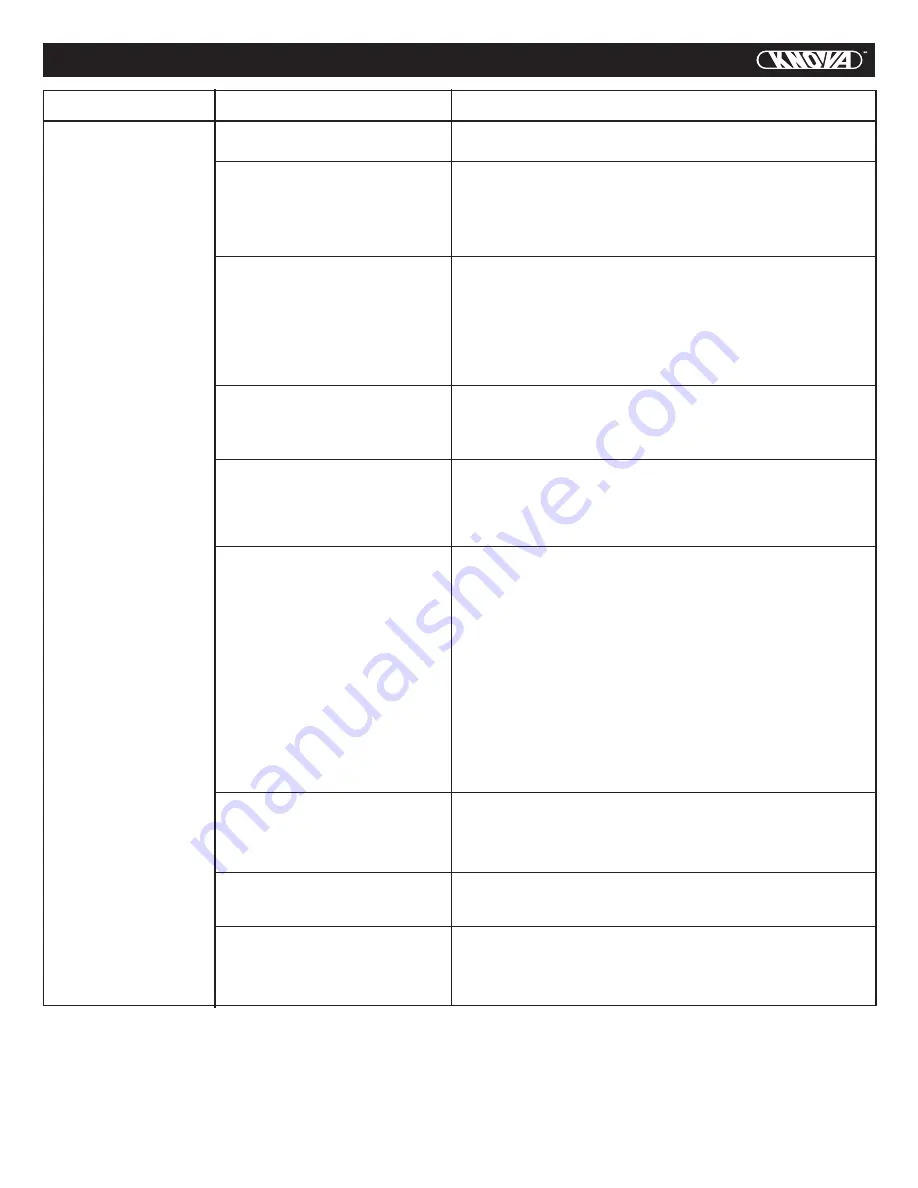

TROUblEShOOTING: MEChANICAl AND ElECTRICAl PROblEMS

Machine will not

start/restart or

repeatedly trips

circuit breaker

or blows fuses.

Overload automatic re-set

has not reset.

Planer frequently trips.

Building circuit breaker

trips or fuse blows.

Loosen electrical connections.

Motor starter failure.

Motor failure.

Miswiring of the machine.

On/off switch failure.

When the planer overloads on the circuit breaker built into

the motor starter, it takes time for the machine to cool down

before restart. Allow unit to adequately cool before

attempting restart. If problem persists, check amp setting

on the motor starter inside the electrical box.

One cause of overloading trips which are not electrical in

nature is too heavy a cut. The solution is to take a lighter

cut. If too deep a cut is not the problem, then check the amp

setting on the overload relay. Match the full load amps on

the motor as noted on the motor plate. If amp setting is

correct then there is probably a loose electrical lead. Check

amp setting on motor starter.

Verify that planer is on a circuit of correct size. If circuit size

is correct, there is probably a loose electrical lead. Check

amp setting on motor starter.

Go through all the electrical connections on the planer

including motor connections, verifying the tightness of each.

Look for any signs of electrical arcing which is a sure

indicator of loose connections or circuit overload.

If electric motor is suspect, you have two options: Have a

qualified electrician test the motor for function, or remove

the motor and take it to a qualified electric motor repair

shop and have it tested.

If the on/off switch is suspect, you have two options: Have

a qualified electrician test the switch for function,

or purchase a new on/off switch and establish if that was

the problem on changeout.

Double check to confirm all electrical connections

are correct and tight.

Examine motor starter for burned or failed components.

If damage is found, replace motor starter. If motor starter

looks okay but is still suspect, you have two options: Have

a qualified electrician test the motor starter for function, or

purchase a new starter and establish if that was the

problem on changeout.

If you have access to a voltmeter, you can separate a

starter failure from a motor failure by first, verifying

incoming voltage and second, checking the voltage between

starter and motor. If incoming voltage is incorrect, you have

a power supply problem.

If voltage between starter and motor is incorrect, you have

a starter problem. If voltage between starter and motor is

correct, you have a motor problem.

Probable Cause

Remedy

Verify unit is connected to power

No incoming power.

Trouble

Summary of Contents for KN CM-15W3

Page 43: ...42 NOTES NOTAS ...

Page 44: ...www knova com mx ...