ADjUSTMENTS

8

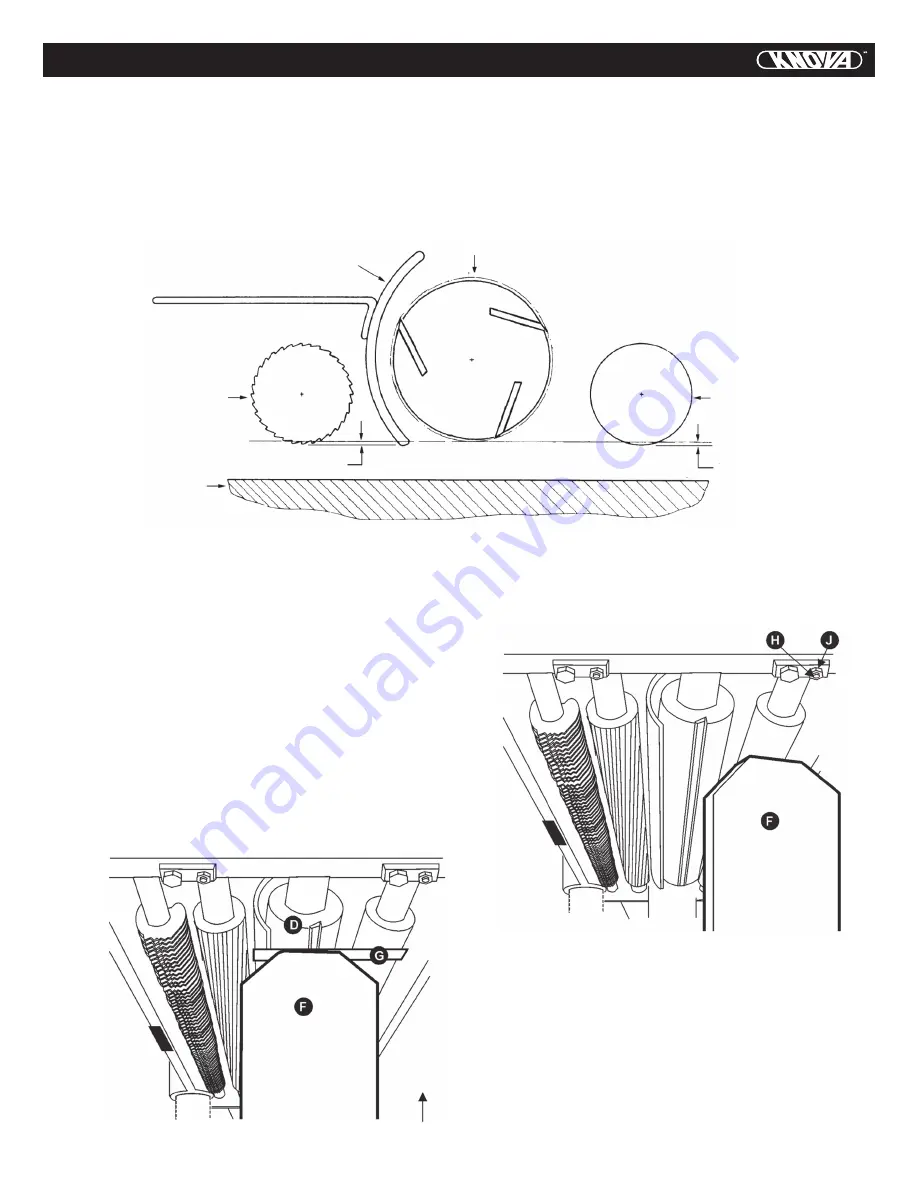

Height of infeed roller, chip breaker and outfeed roller

The infeed roller, chip breaker and outfeed roller are adjusted

at the factory. The height relationship between these items

and the cutterhead is crucial for accurate and safe planing.

The infeed roller, chipbreaker, and outfeed roller should each

be set at 0.02” (0.5mm) below the cutting circle.

See Figure 24.

Figure 24

Figure 26

0.02” (0.5 mm)

0.02” (0.5 mm)

Outfeed roller

If any adjustments are necessary for the infeed roller, chip

breaker, or outfeed roller, they should be done carefully.

Use the following steps as an example of procedure.

NOTE: This procedure uses a home-made gauge block and

feeler gauges, which should be sufficient for most planer

operations. If very precise measurements are desired,

however, use a dial indicator device.

Table

Infeed roller

Chip breaker

Cutterhead

Cutting & roller assembly (side view)

Outfeed Roller Height

1. Disconnect machine from power source.

2. Make sure the knives are set properly as previously

explained under “Knife Adjustment.”

3. Place the gauge block (F, Figure 25) on the table directly

beneath the cutterhead (D, Figure 25).

4. Using a 0.02” (0.5mm) feeler gauge (G, Figure 25) placed

on top of the gauge block, raise the work table until the

knife just touches the feeler gauge when the knife is at its

lowest point. Do not move the work table any farther until

the outfeed roller is adjusted.

5. Remove the feeler gauge and move the gauge block

(F, Figure 25) under one end of the outfeed roller. The

bottom of the outfeed roller should just touch the top of

the gauge block. If an adjustment to the outfeed roller is

necessary, loosen the lock nut (J, Figure 26) and turn

screw (H, Figure 26) until the outfeed roller just touches

the gauge block. Then tighten lock nut (J, Figure 26).

6. Check and

adjust the

opposite end

of the outfeed

roller in the

same manner.

Infeed Roller Height

Use the exact same procedure for checking the infeed roller

as you did for the outfeed roller, Use the .02” (0.5mm) feeler

gauge atop the gauge block. If adjustment is necessary, use

the lock nut and screw on each end of the infeed roller.

Chip breaker Height

The chip breaker breaks off the larger chips before the stock

reaches the cutterhead. Use the gauge block and a

.02” (0.5mm) feeler gauge to check the height of

the chip breaker, following the same procedure as explained

in the previous sections. If adjustment is needed:

1. Remove top cover of planer.

2. Loosen the lock nuts (A, Figure 27) at both ends of the

chip breaker, and turn the set screws (B, Figure 27) to

raise or lower the chip breaker as needed. The set screws

should be turned the same amount.

Figure 25

Gauge

block

Gauge

block

Raise

table

Summary of Contents for KN CM-15W3

Page 43: ...42 NOTES NOTAS ...

Page 44: ...www knova com mx ...