ASSEMBLY AND ADJUSTMENTS

11

1

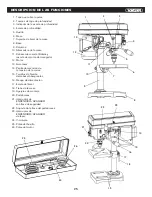

Fig. M

3

4

5

2

10

8

9

11

6

7

10

Fig. N

Vertical Alignment (Fig. M, N)

• Loosen the hex screws (3) using a 3 mm hex wrench,

manually rotate the laser adjusting knob (5) and move

the board from side to side as required until the laser

beam (10) lines up with the marked line (7). Keep

adjusting until the laser beam (10) and the marked line (7)

are aligned. Then carefully tighten the hex screws (3).

• Adjust the other laser beam (11) in the same manner.

Two parallel laser beams (10, 11) should look like

the right side drawing in Fig. N.

NOTE:

The distance between the laser beams will vary

with board thickness; however, the laser beams must be

parallel.

Crosshairs Alignment (Fig. M, O)

• Place a board (12) flat on the table. Do not allow the board

to move from this position; use clamps if needed. Bring

the bit down until it leaves a slight perforation in the

board; then raise it back up.

• Using a 10 mm wrench, slightly loosen the nut (4) so

the laser beam crosses the perforation (13).

Tighten the nut (4).

• Adjust the other laser assembly in the same manner until

the laser beams form crosshairs (14) exactly over

the perforation (13) on the board (12).

• Re-check the vertical alignment

to ensure that the laser

beams did not shift during

the tightening process.

The drilling hole

is now at the center

of crosshairs for

accurate drilling.

• Replace the covers (1)

with the screws (2)

over the laser

assembly on

each side.

14

12

13

Fig. O

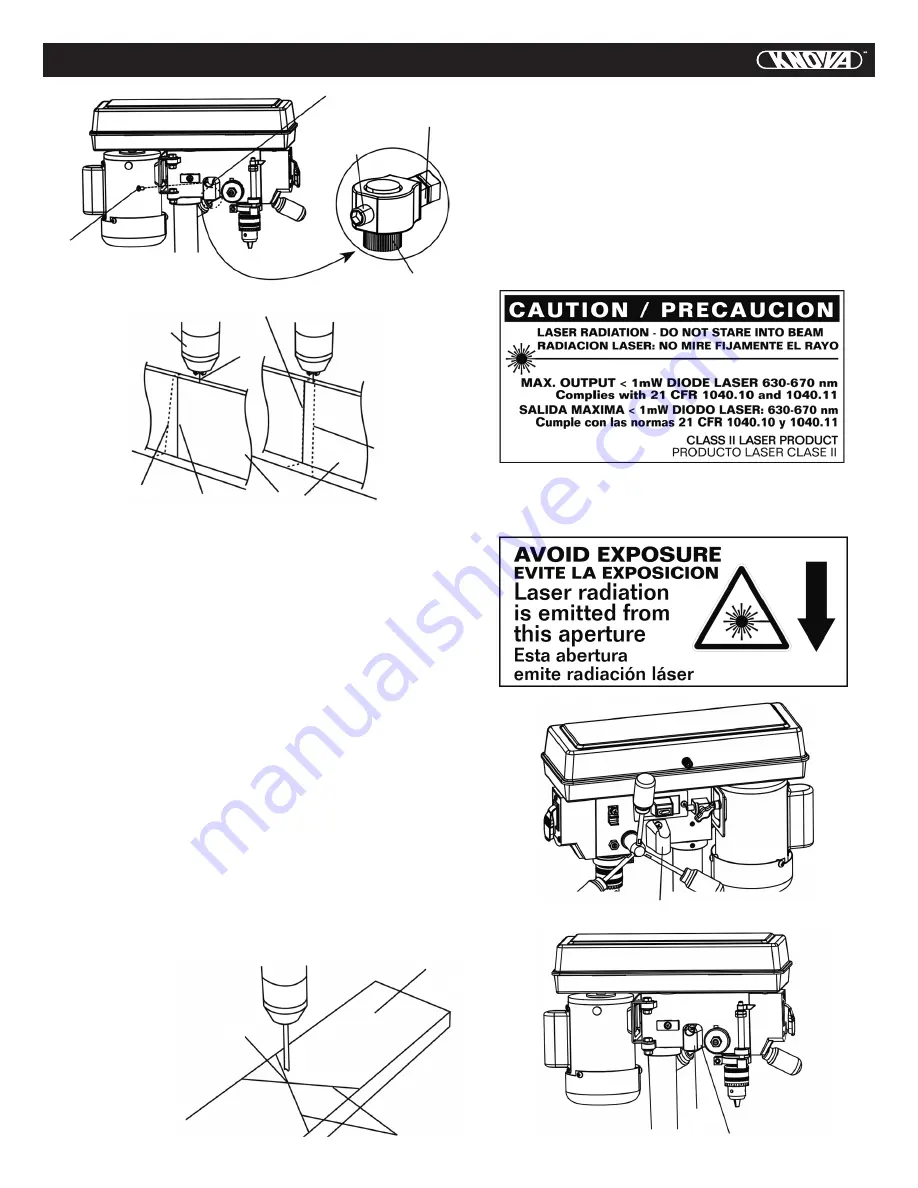

LASER LABEL (FIG. P)

For your convenience and safety, the following labels are

on your laser.

The label (1) on your laser may include the following symbols.

(Fig. P)

V ................................................................................. volts

mW .......................................................................... milliwatts

nm ............................................... wavelength in nanometers

II .................................................................... Class Il Laser

Laser Aperture Label (2): AVOID

EXPOSURE: Laser radiation is emitted from this aperture.

(Fig. P)

2

1

2

Fig. P

Summary of Contents for KN DP-2000N

Page 1: ...KN DP 2000N Bench drill press8 Taladro de columna de banco 203 2 mm ...

Page 18: ...EXPLODED VIEW 17 Bench drill press8 Taladro de columna de banco 203 2 mm KN DP 2000N ...

Page 36: ...Bench drill press8 Taladro de columna de banco 203 2 mm KN DP 2000N DIAGRAMA DE ENSAMBLADO 35 ...

Page 37: ...NOTES NOTAS 36 ...

Page 38: ...NOTES NOTAS 37 ...

Page 39: ...NOTES NOTAS 38 ...

Page 40: ...www knova com mx ...