15

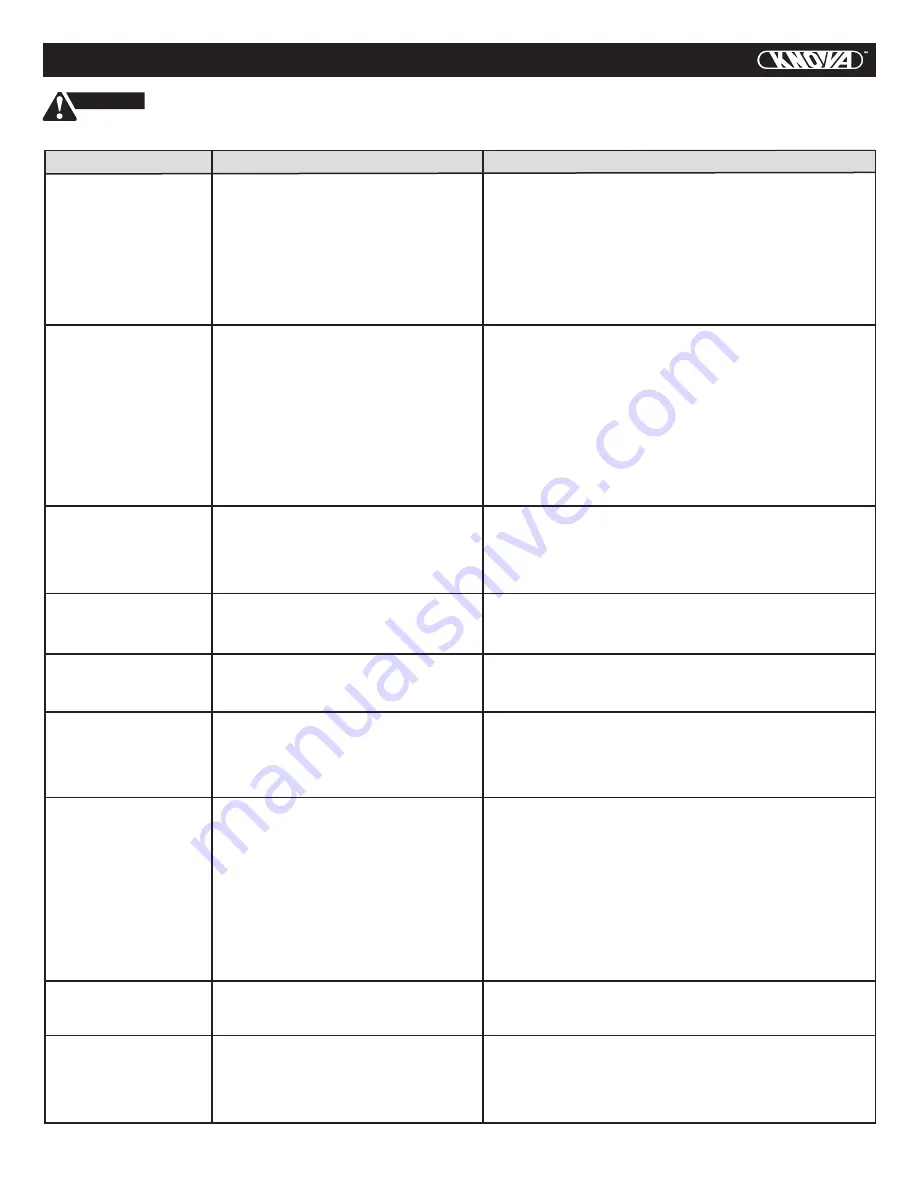

TROUBLESHOOTING

POSSIBLE SOLUTION

PROBLEM

POSSIBLE CAUSES

• Drill bit burns

• Run out of drill bit

point/drilled hole

not round.

• Wood splinters

on underside.

• Workpiece torn

loose from hand.

• Drill bit binds

in workpiece.

• Excessive drill bit

runout or wobble.

• Quill returns too

slow or too fast.

• Chuck will not stay

attached to spindle.

It falls off when

trying to install.

• Incorrect speed.

• Chips

not coming out of hole.

• Dull

drill bit.

• Feeding

too slowly.

• Not

lubricated.

• Grain in wood or lengths of cutting

flutes and/or angles not equal.

• Bent

drill bit.

• No backup material under

workpiece.

• Not supported or clamped properly

• Workpiece pinching drill bit,

or excessive feed pressure.

• Improper

belt tension.

• Bent drill bit.

• Worn

bearings.

• Drill

bit not properly installed

in chuck.

• Chuck not properly installed.

• Coil spring has improper tension.

• Dirt, grease, or oil on the tapered

inside surface of chuck or on the

spindle’s tapered surface.

• Change speed. See section

“SPEEDS AND BELT PLACEMENT”.

• Retract

drill frequently to clear chips.

• Resharpen

drill bit.

• Feed

fast enough – allow drill to cut.

• Lubricate

drill.

• Resharpen drill bit correctly.

• Replace

drill bit.

• Use backup material. See section

“BASIC DRILL PRESS OPERATION”.

• Support workpiece or clamp it. See section

“BASIC DRILL PRESS OPERATION”.

• Support workpiece or clamp it. See section

“BASIC DRILL PRESS OPERATION”.

• Adjust

tension. See section “BELT TENSION”.

• Replace drill bit.

• Replace

bearings.

• Install

drill bit properly. See section “BASIC DRILL

PRESS OPERATION” and “INSTALLING DRILL

BIT IN CHUCK”.

• Install chuck properly. See section

“INSTALLING THE CHUCK”.

• Adjust spring tension. See section

“QUILL RETURN SPRING”.

• Using a non-alcohol based cleaner, clean the tapered

surface of the chuck and spindle to remove all dirt,

grease and oil. See section

“INSTALLING THE CHUCK”.

• Noisy operation

• Incorrect belt tension.

• Dry

spindle.

• Loose

spindle pulley.

• Loose

motor pulley.

WARNING

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power source

before making any adjustments.

• Adjust tension. See section “BELT TENSION”.

• Lubricate

spindle.

• Check

tightness of retaining nut on pulley,

and tighten if necessary.

• Tighten

set screw in motor pulley.

Summary of Contents for KN DP-2000N

Page 1: ...KN DP 2000N Bench drill press8 Taladro de columna de banco 203 2 mm ...

Page 18: ...EXPLODED VIEW 17 Bench drill press8 Taladro de columna de banco 203 2 mm KN DP 2000N ...

Page 36: ...Bench drill press8 Taladro de columna de banco 203 2 mm KN DP 2000N DIAGRAMA DE ENSAMBLADO 35 ...

Page 37: ...NOTES NOTAS 36 ...

Page 38: ...NOTES NOTAS 37 ...

Page 39: ...NOTES NOTAS 38 ...

Page 40: ...www knova com mx ...